Innovative Raumfahrttechnologien live entfaltet und präsentiert.

November 2025

Innovative Raumfahrttechnologien live entfaltet und präsentiert.

November 2025

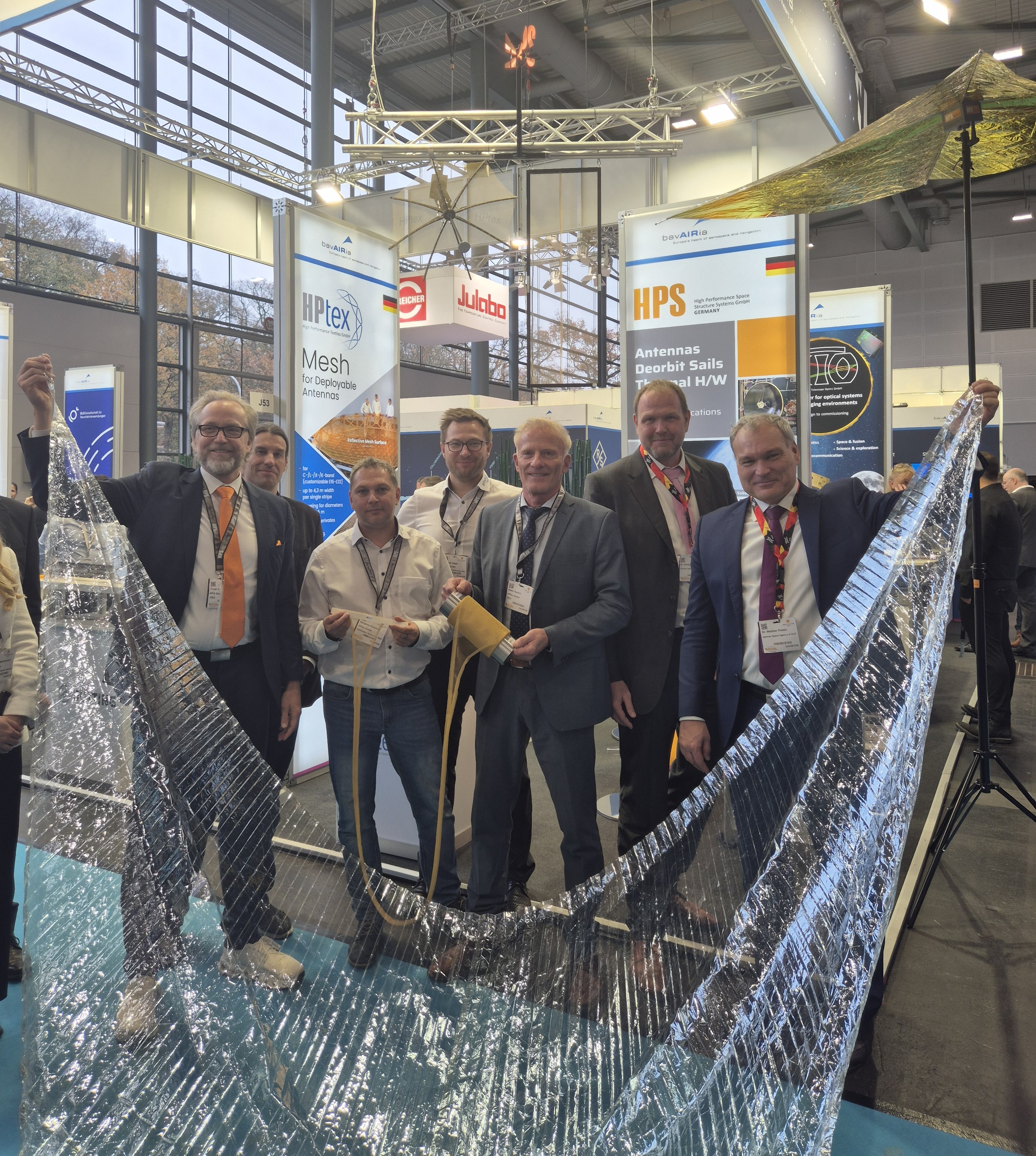

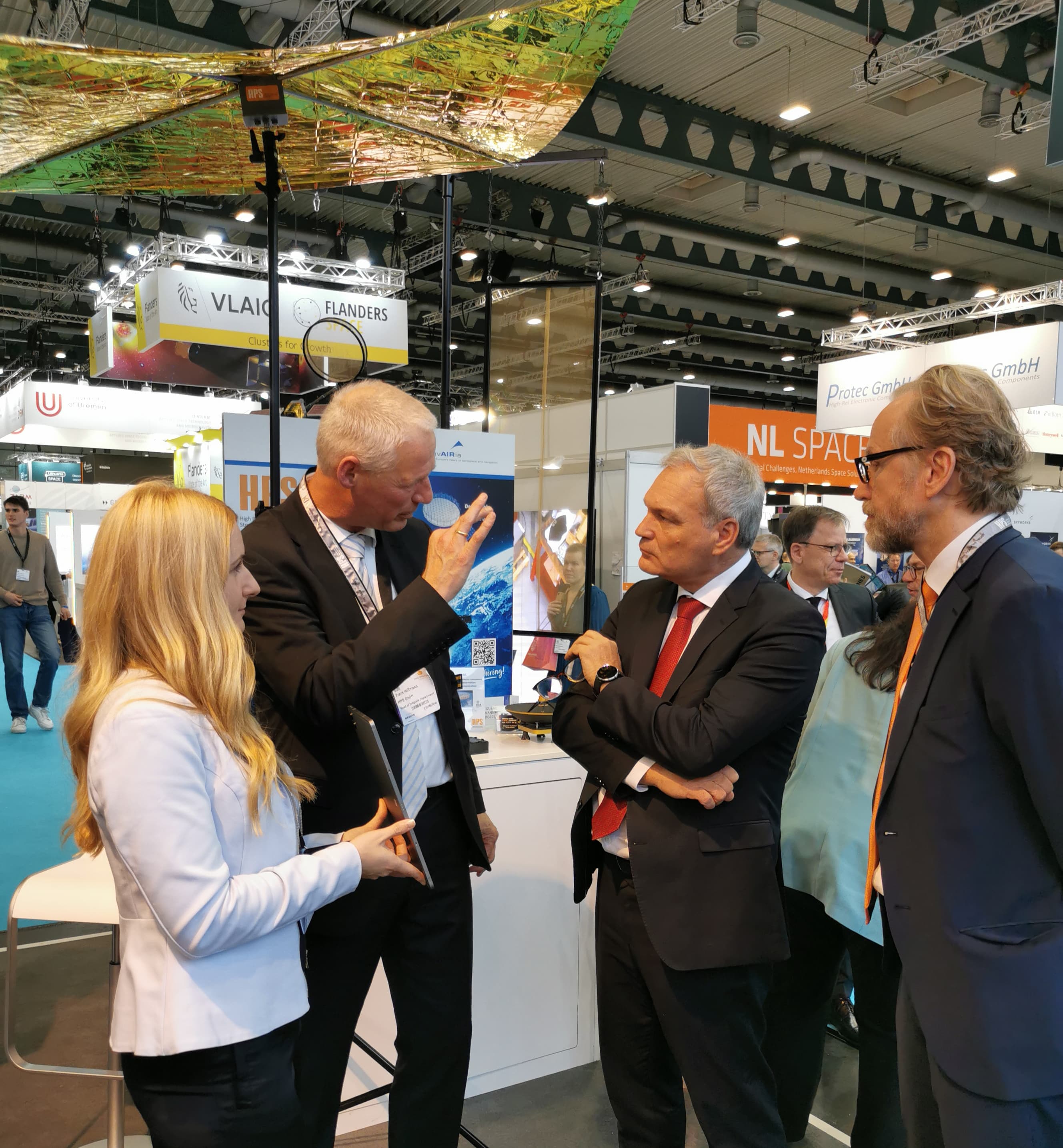

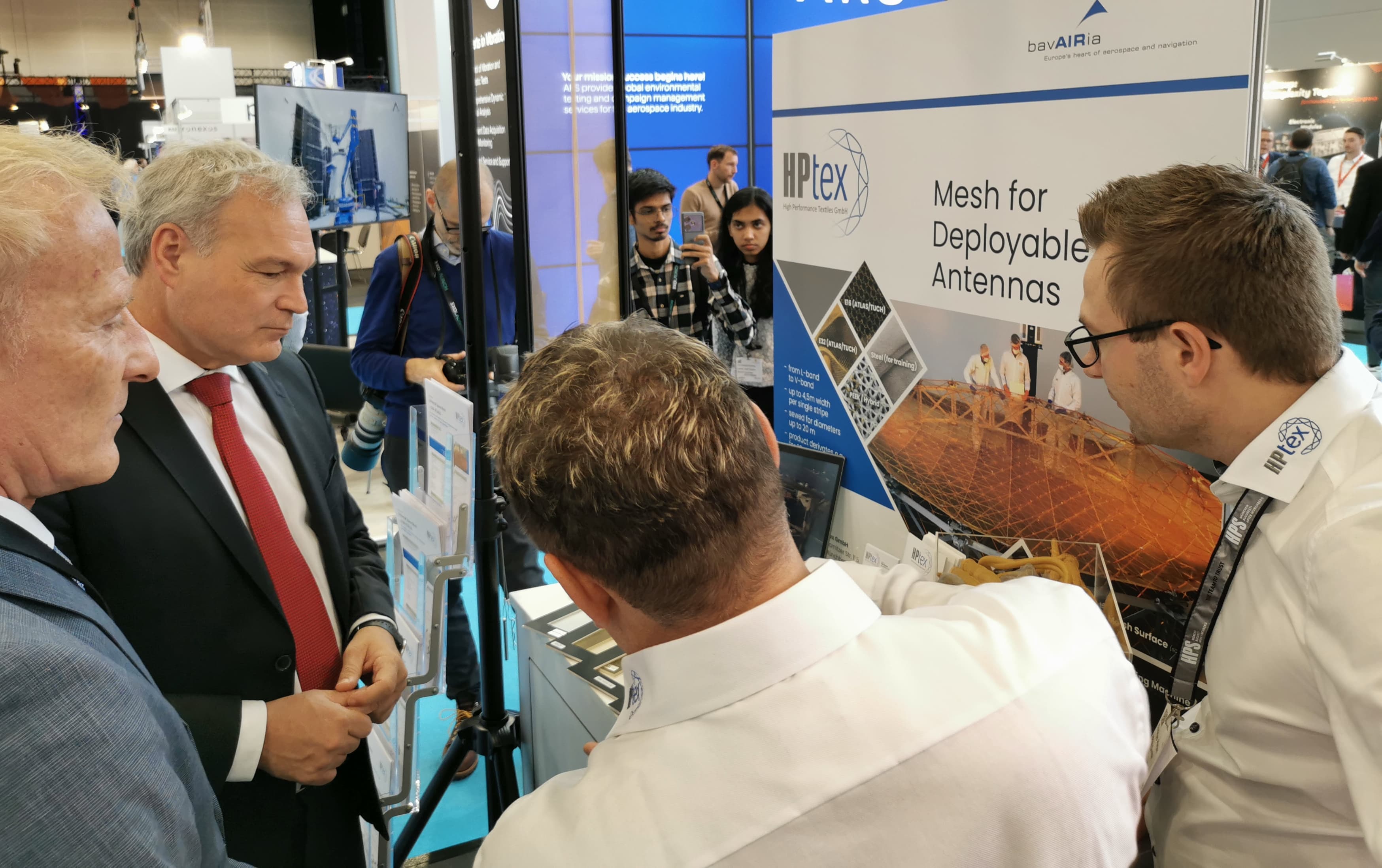

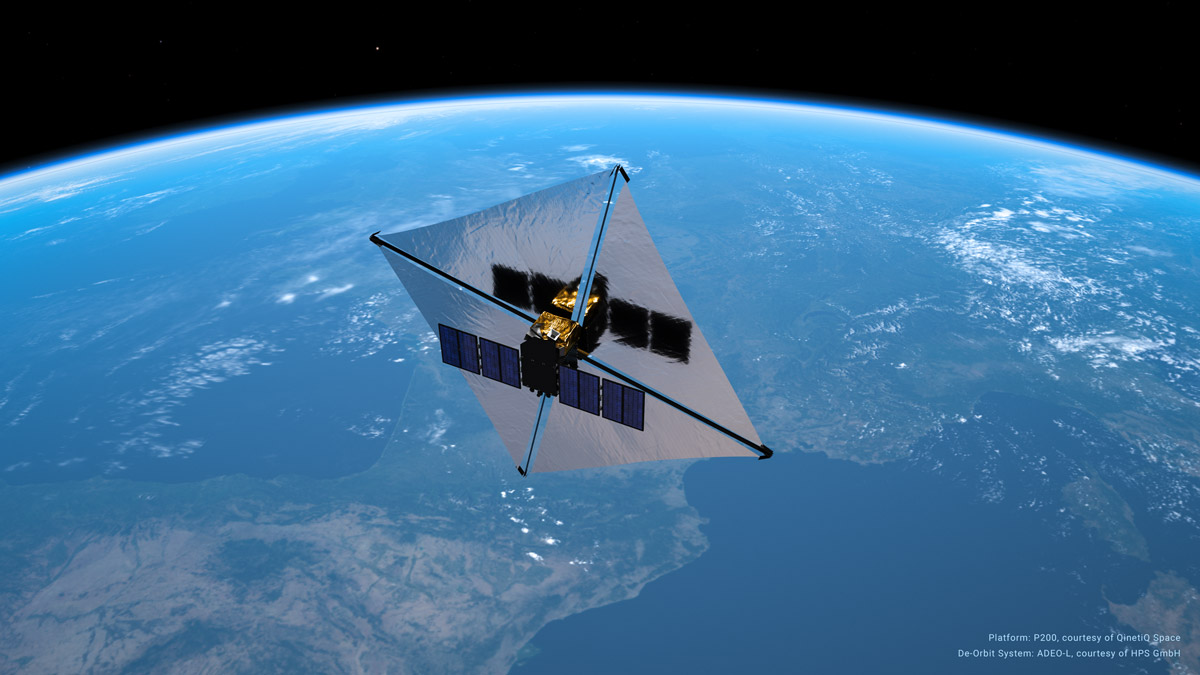

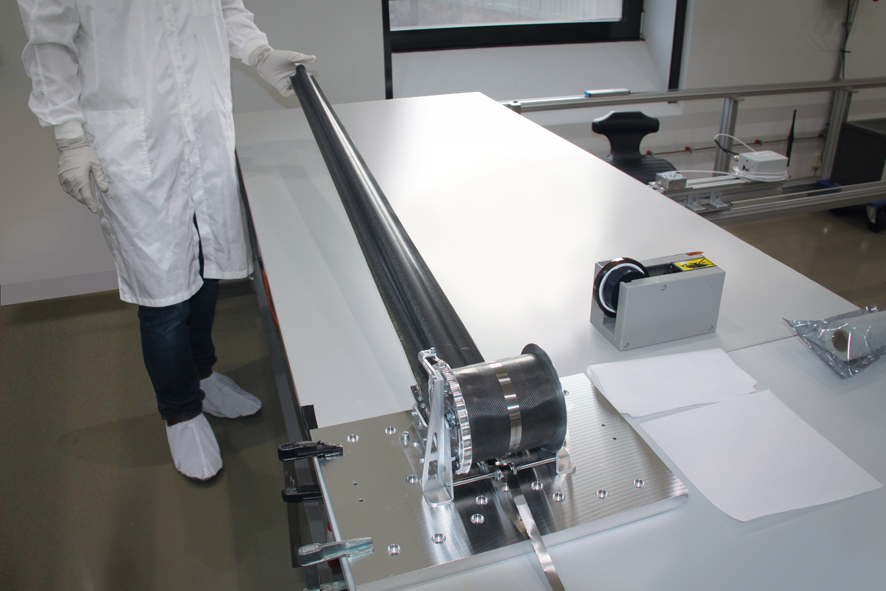

Am Mittwoch, dem 19. November 2025, empfing die HPS GmbH auf ihrem Messestand der Space Tech Expo 2025 in Bremen den DLR-Raumfahrtchef Dr. Walther Pelzer. Die CEOs und führende Vertreter von HPS München und deren Joint-Venture HPtex Münchberg informierten die hochrangigen Gäste der deutschen Raumfahrtagentur über die neuesten Fortschritte im Bereich der weltraumtechnischen Innovationen.

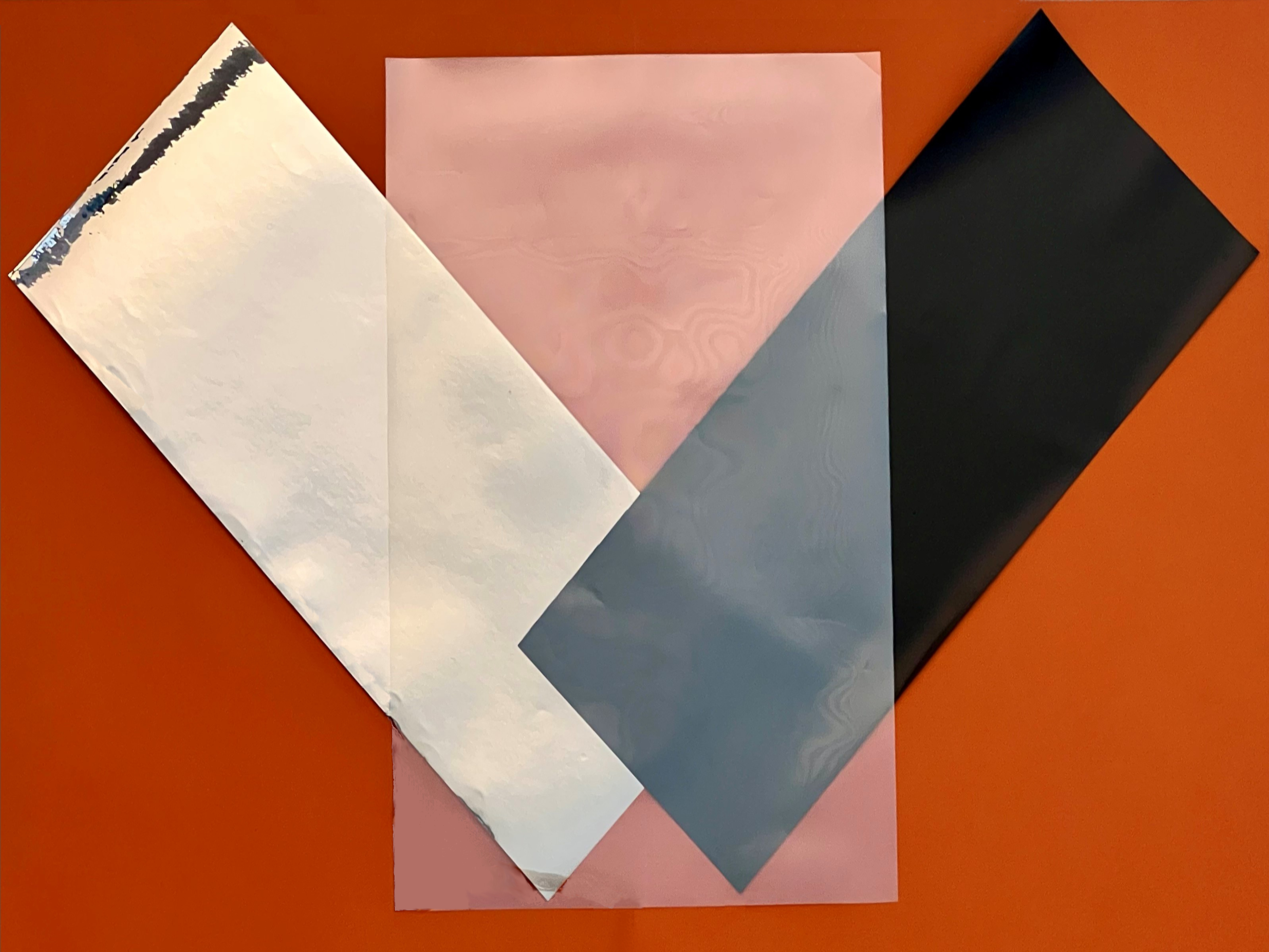

Im Rahmen des Besuchs wurden den Gästen zwei herausragende Entwicklungen live vorgestellt (siehe Bild):

Beide Technologien wurden zeitgleich und live am Stand als eindrucksvolle Demonstration entfaltet; sie stammen aus renommierten ESA-Technologieprogrammen wie GSTP und ARTES, welche den europäischen Raumfahrtunternehmen als Basis für stetige Wettbewerbsfähigkeit bieten.

HPS und HPtex waren Teil des von @BavAIRia großartig organisierten und schön arrangierten bayerischen Gemeinschaftsstandes.

Innovative Space Technology for Sustainable Satellite Disposal and Mitigation of Space Debris in the Spotlight

Unusual Event at SpaceTech Expo Bremen: HPS Hardware Handover at the OHB Stand

November 2025

Unusual Event at SpaceTech Expo Bremen: HPS Hardware Handover at the OHB Stand

On 19.11.2025 at 15:30, an extraordinary event for a trade fair of this kind took place at the SpaceTech Expo stand of the German space company OHB in Bremen: For the first time, genuine ADEO hardware was ceremoniously and personally handed over between HPS (CEO Ernst K. Pfeiffer and CFO Peter Rauhut) and OHB (CEO Chiara Pedersoli and Member of Management Board Gianaldo Mantovani) for integration into a new satellite constellation – marking a strong, tangible sign of innovation and sustainability in the space sector.

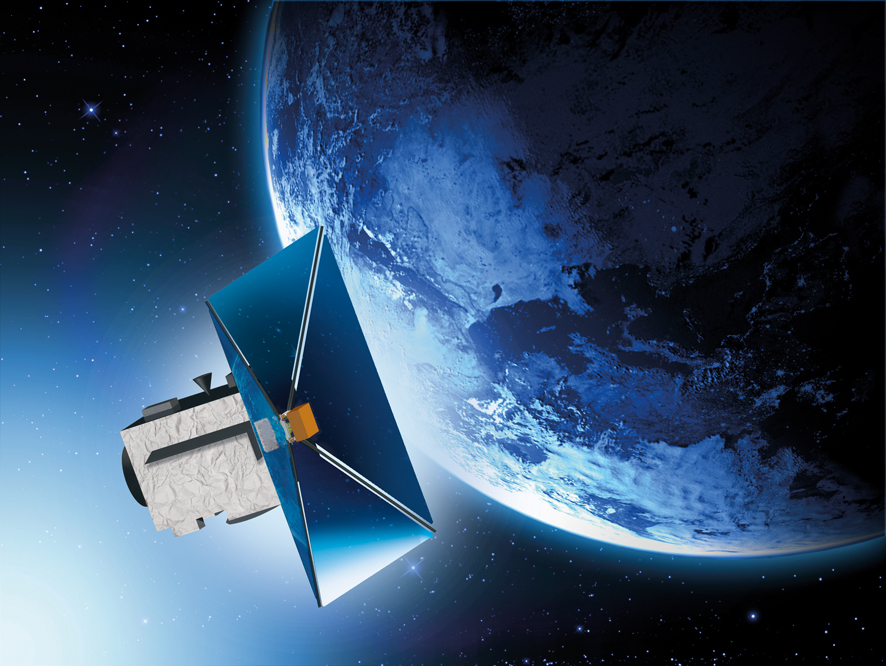

HPS GmbH Supplies Drag Sails for Safe Satellite Deorbiting

The Munich-based high-tech company HPS GmbH (headquartered in Munich, with a subsidiary in Bucharest) delivered four ordered ADEO-N(ano) class drag sails to its client, the renowned space company OHB, in Bremen. The ADEO modules are essential for the accelerated deorbiting of satellites at the end of their service life, ensuring compliance with the legal requirement of a maximum five-year deorbit period.

Technological Responsibility and Collaboration for Sustainable Space Activities

HPS is the developer and manufacturer of the ADEO product family of drag sails, designed for satellites of all sizes and weight classes in LEO and MEO orbits. Both companies – HPS and OHB – are also among the first signatories of the ESA Zero Debris Charter and are jointly as well as individually committed to its consistent implementation. By integrating ADEO into its LEO-PNT satellites, OHB underscores its top-level support for sustainable space activities, as well as for close collaboration between large system integrators and SMEs, which is of great and ever-increasing importance, especially in the context of European defence initiatives.

Significance of the Partnership and the Project

For HPS, collaboration with OHB is of particular relevance. For example, HPS supplied the downlink antenna for the OHB satellite of the HERA mission. The current delivery concerns a space programme of immense reach: the LEO-PNT satellite constellation is part of the ESA programme for the next generation of highly precise navigation and positioning technology in space. In general, ESA is committed with great dedication to consistently implementing its five-year deorbit requirements in its missions.

SpaceTech Expo Bremen as a Stage for Innovation and Sustainability

With its numerous space technology models and information stands from around one thousand exhibitors, the SpaceTech Expo in Bremen provided a unique backdrop for the handover of the ADEO modules, which are scheduled to launch into space in 2026. The timing of the fair and the already planned handover coincided by chance, so both companies spontaneously decided to celebrate this event as an extraordinary moment.

Dr. Ernst K. Pfeiffer, CEO of HPS GmbH, emphasised: “There is no better way to draw attention to pioneering technologies for the avoidance of space debris with a strong presence at by far the most important space fair in Europe – where all relevant institutions and companies of the industry are gathered. The ADEO modules of the N-version delivered here, are among the most in-demand ADEO-class of drag sails currently available.”

Current Status of the Satellite Project in Kruibeke, Belgium

November 2025

Back in July this year, it was announced that Redwire Belgium has also adopted HPS’s ADEO drag sail technology for satellite deorbiting. HPS is a global pioneer in developing sustainable space resource utilisation, and with its ADEO drag sail product family for all satellite classes in LEO orbits, it has established the international gold standard in deorbiting technology.

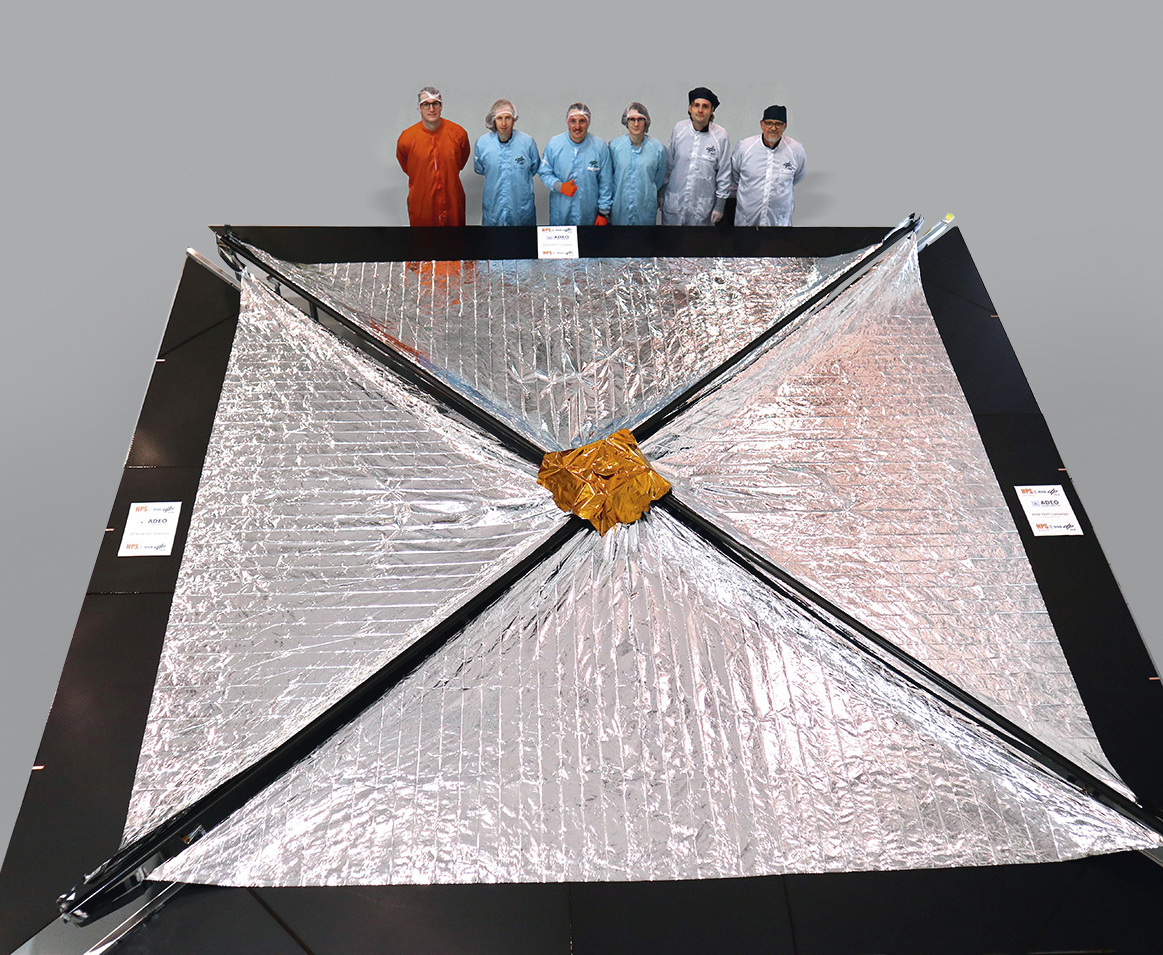

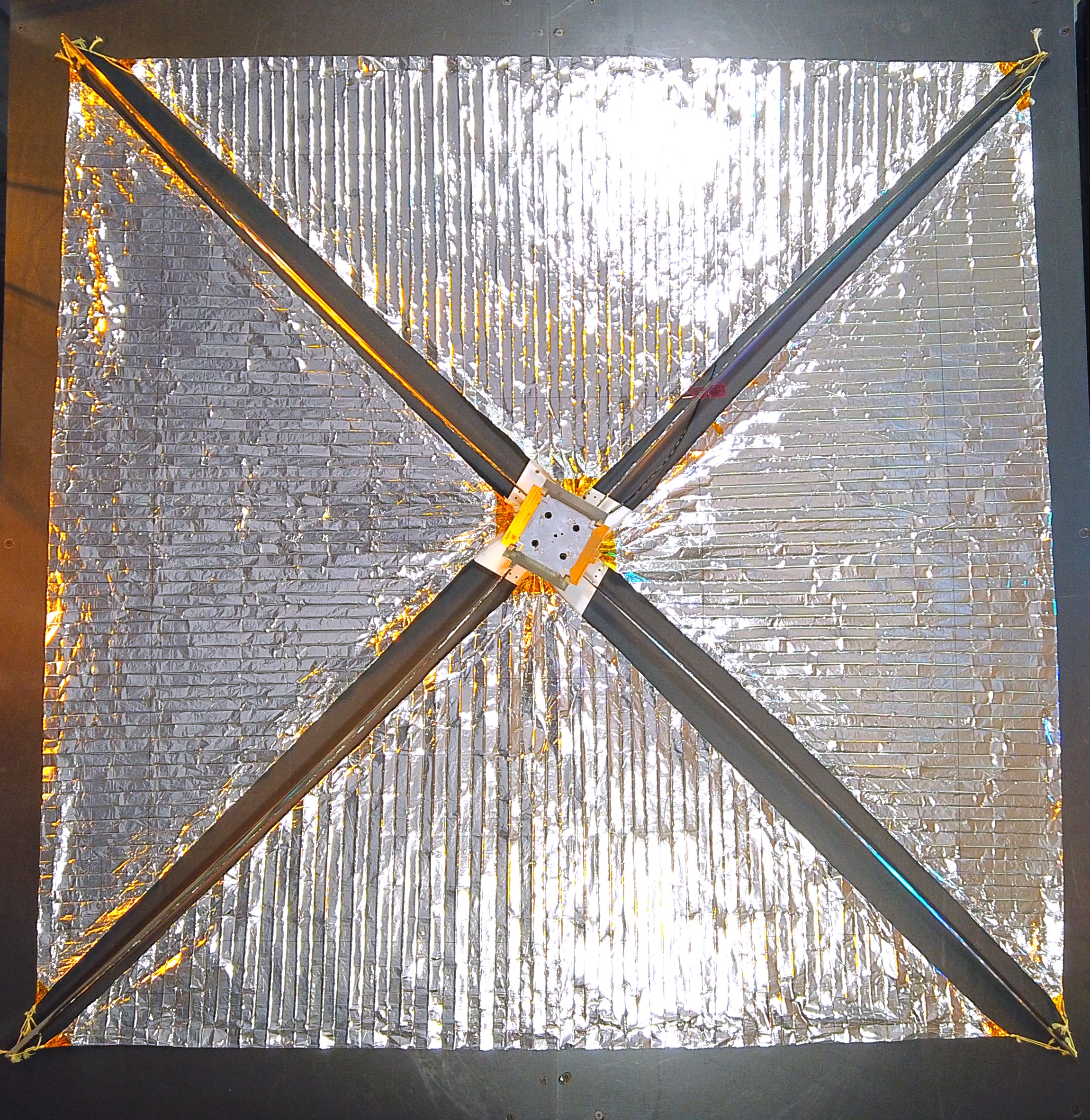

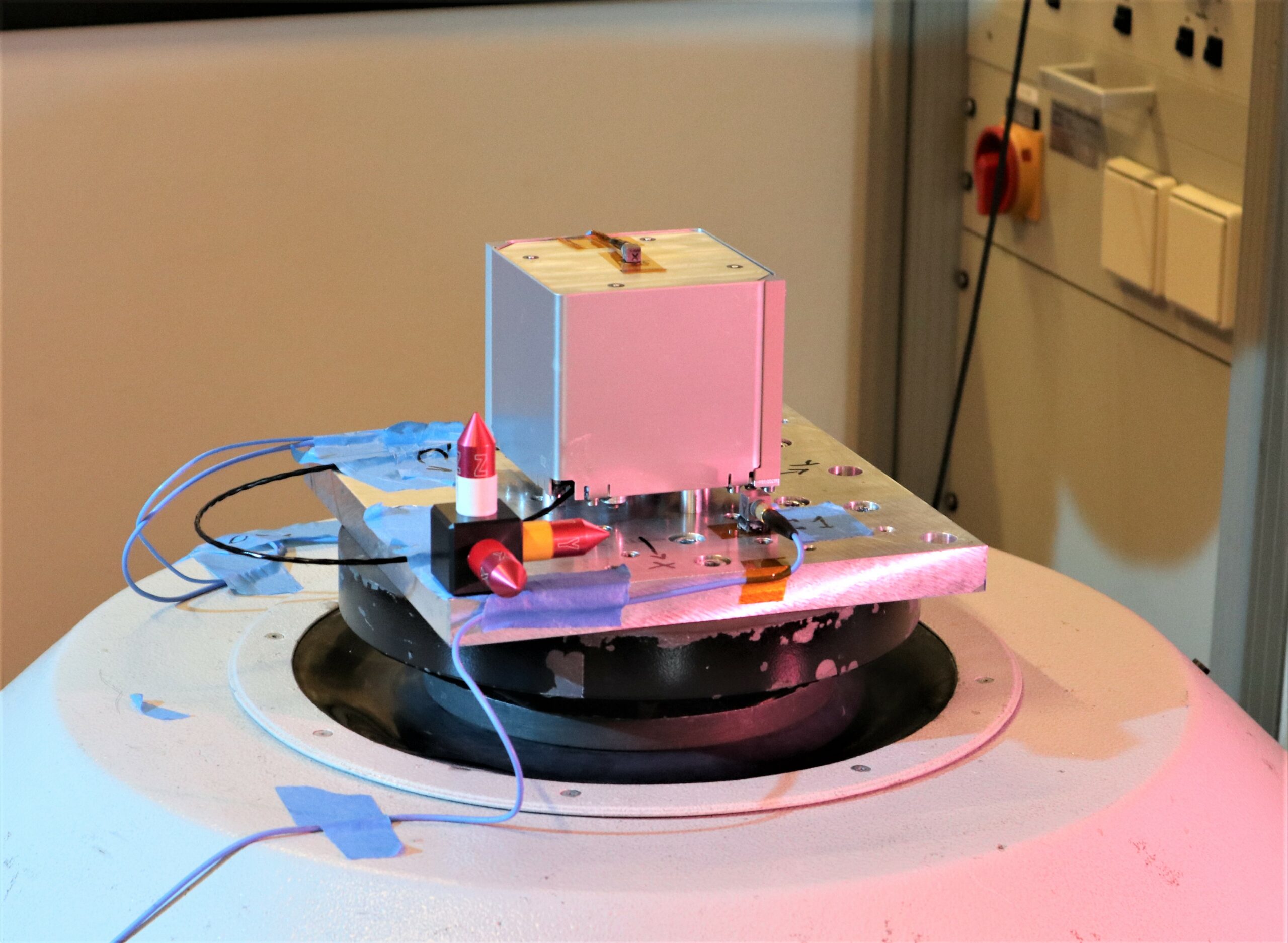

For Redwire’s current satellite project, HPS delivered the ADEO-L version – constructed under the ESA-GSTP-project umbrella of ADEO2 – of the drag sail in the summer. The Redwire spacecraft, developed specifically for an IOD/IOV mission in LEO for the European Commission, has medium-sized dimensions and therefore requires the ADEO-L deorbit module, featuring a surface area of 25 m².

The ADEO2 deorbit module was successfully integrated onto the satellite at the Redwire Satellite Processing Facility in Kruibeke, Belgium, on 3rd and 4th November 2025.

The next step will be comprehensive system tests of the fully integrated satellite—including environmental tests such as vibration, acoustic, and thermal vacuum (TVAC) testing—scheduled for the first quarter of 2026. The launch is planned to take place later in 2026 aboard a European launch vehicle, which is yet to be selected. Deployment of the drag sail for rapid and efficient deorbiting at the end of the mission is planned for about 1.5 years after launch.

As an integrated aerospace and defence company, Redwire focuses on autonomous systems and cross-domain operations utilising digital technology and AI automation. Redwire’s approximately 1,300 employees in the United States and Europe are developing innovative space and airborne platforms that are shaping the future of multidomain operations. The Belgian facility of Redwire can look back on more than 40 years of experience in spaceflight, during which it has developed spacecraft platforms and delivered innovative technologies for groundbreaking ESA programmes.

New in-orbit demonstration CubeSat project with Deployable Membranes based on ADEO-M

October 2025

The OPTIMIST mission, kicked-off in August 2025 to undergo a Phase A/B1, will involve a CubeSat deployed at an altitude of about 550 kilometers for one year. Its main goal will be to mature and validate the SAILOR payload technologies via statistically measuring near-Earth submillimeter, millimeter and centimeter sized debris populations and using a large deployable membrane (5–7 m²) equipped with acoustic sensors and a camera system. These instruments will detect and analyze impacts from small debris, providing valuable data for future, larger-scale missions: OPTIMIST will field-test essential technologies for the final target, the full-scale-mission SAILOR, which is dedicated to the scientific objective to investigate in-situ small space debris and its evolution. The results of the precursor mission OPTIMIST, to be launched in late 2027, will support the feasibility and design of a robust debris detection platform, which can be used with several satellites in the layer of a large satellite constellation for better debris impact predictions.

The first milestone of the project has already been completed with successfully closing the Mission Baseline Review with ESA. The Phase A/B1 study with breadboarding activities assesses technologies identified in SAILOR’s earlier phase, define mission architecture and evaluate launch options—favoring European launchers. Trade-off analyses ensure the mission is designed for maximum reliability and cost-efficiency, while meeting all technical requirements.

Under the project-lead of C3S (Hungary), HPS-Germany is responsible for the deployable membrane module, which is based for the OPTIMIST Mission on HPS’s deorbit module ADEO-M. HPS-Romania will perform the membrane manufacturing and the acoustic sensor bonding process. Further project partner under the prime C3S is University of Kent (UK) ensures extensive knowledge at the space debris science part and access to facilities to perform experimental simulation of hypervelocity impacts.

With SAILOR’s closure of Phase A and start of Phase B1 and the incorporated by the OPTIMIST precursor study, the SAILOR-project is poised to make significant progress toward safer and more effective management of space debris, paving the way for future missions that will help protect Earth’s orbital environment. SAILOR and OPTIMIST are part of ESA’s Space Safety Programme (S2P), which is dedicated to protect Earth’s and in-orbit infrastructure from dangers from and in space.

Redwire Belgium also relies on the gold standard of deorbit technology: the ADEO dragsail from HPS

July 2025

Twelve years ago, it was just an idea: quickly and inexpensively removing spent satellites from space traffic – quite simply with an automatic brake sail. Today, HPS, the global pioneer of development to ensure the sustainable use of space as a resource, is the international gold standard in deorbit technology with its ADEO dragsail product family for all classes of satellites on LEO orbits. From experimental university projects to global constellations: satellite manufacturers and operators from the EU and Asia, Australia and America rely on ADEO to reliably dispose of their spacecraft within the prescribed window of a maximum of five years after the end of operation.

The latest example: US-corporation Redwire´s branch in Belgium. The integrated aerospace and defense company focusses on autonomous systems and multi-domain operations leveraging digital engineering and AI automation. Redwire’s approximately 1,300 employees located throughout the United States and Europe are committed to delivering innovative space and airborne platforms transforming the future of multi-domain operations.

Redwire’s facility in Belgium has more than 40 years of spaceflight heritage developing spacecraft platforms and success delivering innovative technology for game-changing ESA programs.

The spacecraft specifically designed for this mission will operate on LEO. Its weight as a midsize satellite requires a deorbit module of the ADEO-2 class series, which is now with integrator Redwire. HPS CEO Ernst K. Pfeiffer: “We at HPS in Munich and Bucharest are delighted to be able to count this prestigious customer Redwire among our ADEO customers. The importance of Redwire´s role model function for others as a responsible space company cannot be overestimated.”

Successful delivery of ADEO deorbit modules to ISISPACE (NL)

July 2025

HPS, one of the industrial pioneers worldwide in the development of sustainable use of space as a resource, is now the international gold standard in deorbit technology with its ADEO t dragsail product family for all satellite classes on LEO orbits. Satellite manufacturers and operators from the EU and Asia, Australia and America use an ADEO to reliably dispose of their spacecraft within the prescribed time window of a maximum of five years after the end of operation.

The most recent example: ISISPACE, Dutch satellite system integrator and space infrastructure provider, offers innovative turnkey solutions for space missions worldwide. Founded in Delft (NL) in 2006, the company specializes in the design, development, production, testing, launch and operation of small satellite platforms, both for individual missions and for constellations. The first ADEO for an ISISPACE satellite, an ADEO-Nx class module (only 745 gr., integrable into cubesat rails, TRL9-based, short delivery time), was delivered by the HPS project team at the end of June. Yesterday, July 1, 2025, the team personally handed over the CleanGreen Certificate on site in Delft to ISISPACE coinciding with the opening of the “Symposium on Space Sailing”

HPS CEO Ernst K. Pfeiffer hopes to celebrate the “possible start of a great collaboration with one of the most prominent and successful small satellite specialists in Europe”.

ISISPACE’s vertically integrated approach has been proven in more than 50 missions carried out in a wide range of solutions and applications, including Earth observation, IOD/IOV and many others. ISISPACE is headquartered in the Netherlands and employs around 120 people from more than 30 countries.

ADEO shines at the “International Symposium on Space Sailing” 2025!

July 2025

This week, at the “7th ISSS” in Delft (NL), HPS is proud to represent Europe’s leading deorbit solution: ADEO – the dragsail for a sustainable orbit.

With the presentation by our project manager Dorottya Milankovich on Day 1, June 30th, we’re showcasing:

HPS CEO on site: “We are proud to be part of this very specialised space sailing family, ranging from solar sail developers to dragsail suppliers, from radiation scientists to sailing simulation experts.”

In total 82 participants from all over the world listened on site and via online, from USA to Philippines, from NASA to TU Delft.

This Symposium proved:

ADEO is not just a product – HPS is one of the world market leaders for deorbit dragsail modules.

Let’s sail toward a cleaner orbit!

#ADEO #Dragsail #ZeroDebris #CleanSpace #SpaceDebris #ISSS2025 #SpaceSustainability #HPS #SpaceTech #Delft #TUDelft #LEO #SpaceSailing #ESA #SatelliteDeorbiting #Deployables #SolarSailing

Ernst K. Pfeiffer: Summary of the Zero Debris Symposium and Workshop

June 2025

Great: the Zero-Debris Symposium and Workshop on the Zero-Debris Booklet brought a full house to ESA’s European Space Operation Center from June 10 to 12. The program covered all relevant aspects of the topic with slots for exchanging experiences on developments over the last 12 months, panel discussions such as “Zero Debris Progress & Challenges” and presentations such as the one by HPS CEO Ernst K. Pfeiffer on “How we work with the Zero Debris Booklet”. HPS High Performance Space Structure Systems GmbH is one of the central suppliers in this “clean space” sector – but not only that: it is also one of the driving industrial forces when it comes to making space travel sustainable. To this end, the company has been investing heavily in corresponding technologies for over ten years and today covers the demand for towing sail modules (ADEO), is working on deployable membranes for the in-situ measurement of small debris (SAILOR) and has recently developed non-reflective films (ProFilm) for “dark skies”. At the end of the event, Pfeiffer summarized his summary in the following positions:

Pfeiffer particularly emphasized the positive spirit of optimism of all participants, which was carried and spread by the space giants such as TAS and OHB, the midcaps such as GMV or FEV etamax, as well as NewSpace companies such as D-Orbit, RIVADA, VYOMA, Astroscale, Clearspace, investors, lawyers, institutes, EIC and national space agencies. Special thanks went to the organizers from ESA’s Space Safety Department, in particular Quentin Verspieren, Sacha Bressollette and Calum Turner.

HPS prominently present at ESA’s Zero Debris Week

June 2025

From 10 to 12 June 2025, everything at ESA’s European Space Operations Center in Darmstadt will be dominated by the highly ambitious “Zero Debris Program” of Europe’s space agency. The days are divided into two large action chapters: from June 10-11 at noon, the Zero Debris Future Symposium will focus in particular on high-level discussions of non-technical aspects, such as the future direction of the Zero Debris Initiative and its community, as well as commercial and political challenges in connection with orbital debris. Day two, June 11-12 at noon, will be dedicated to another working session on the Zero Debris Technical Booklet. Among other things, the technical leaders who will oversee the next edition of the booklet will be elected on this occasion. The participating organizations will also discuss how they have used the booklet so far, how the work on the booklet should be regulated and organized, and how the technologies listed in the booklet can be implemented.

The Zero Debris Technical Booklet published on January 15, 2025 lists technologies that ESA believes will contribute to achieving the goal of zero debris by 2030. The booklet is essentially a technical zero debris “to-do list”. The aim is to minimize the release of new debris and reduce its impact on people, infrastructure and the Earth’s environment.

Developed by a team of engineers, operators, lawyers, scientists and policy experts from a wide range of institutions in the Zero Debris community, the booklet identifies six key technology objectives that are essential to achieving Zero Debris goals:

ESA itself is focusing its efforts on the development of debris-resistant materials and technologies, the design of satellites that can be easily removed from orbit and do not burn up on re-entry into the atmosphere, and finally the development of standardized interfaces for efficient removal in the event of a malfunction.

Beyond the satellite itself, the focus is also on new systems to remove all components of the launch vehicle from orbit. Another source of debris are small particles released by certain types of fuel and pyrotechnics in orbit during deployment. Alternatives are to be developed for this. The distribution of space debris around the Earth highlights the importance of collision avoidance measures. Once the satellites are in operation, much can be gained by optimizing collision avoidance processes and space traffic management. A key element is improving tracking capabilities for smaller, currently untrackable debris objects to refine risk assessment.

Operational practices can also be optimized, supported by new technologies to improve communication infrastructure and spacecraft health monitoring. At the end of a mission, the deorbit and re-entry process (for LEO and MEO satellites) and the impact on the environment need to be considered. Active debris removal services are required in orbit, as well as reducing the environmental impact of debris re-entry on the ocean and atmosphere, which will begin with further research.

Participation in ESA’s Zero Debris Initiative is a top priority for HPS – and accordingly, HPS CEO Ernst K. Pfeiffer will take part in the central program items on both days in Darmstadt. HPS’s commitment goes far beyond academic aspects, as the company has already made a remarkable contribution to avoiding space debris with its ADEO Deorbit Module product family by rapidly removing disused satellites from orbit; in addition, it is already on the threshold of Phase B with initial developments for a detector for previously undetectable particles from 0.1 to 10 mm in size called SAILOR.

The HPS boss doesn’t mince his words when it comes to emphasizing the importance of the ESA initiative: “The Zero-Debris Initiative is a start, but we are still a long way to our goal. We still have to reach an important milestone, and that is directly in the minds of the target groups: In parts of the space community, the debris issue is still seen as merely a green nice-to-have topic. This is absolutely wrong: it is an issue of great commercial interest and value, because if the littering of orbits continues at this rate, economically viable activities in space will soon be history – and that so before they have really taken off.”

HPS puts ADEO know-how at the service of ESA´s Hungarian Prime C3S

May 2025

It seems to be a basic law of nature: Wherever and however humans are active, they end up producing large quantities of waste. To suppress the problem, many terrestrial areas, the oceans and, in recent decades, outer space itself have become dumping grounds. However, the latter in particular is now threatening to take radical revenge, as flying debris from previous space missions is increasingly becoming a threat to all other activities, especially in the most frequented orbits between 200 and 1200 kilometers.

While large debris such as burnt-out rocket stages are the easiest to detect and can be avoided by new guests in orbit, it is the small projectiles, flying with 5-10 km/s orbital speed, which have often shrunk below millimeter size as a result of previous fragmentations, that pose the greatest threats. Even one millimeter-sized debris impact can render a satellite inoperable. Emerging their threat further, their flux increases significantly as their size decreases, with the consequence that the much more frequent impacts of debris of this size can pose a far greater risk to space operations than the more dramatic catastrophic incidents.

However, only larger debris can be observed and tracked from the ground – but not in the critical range of 0.1 to 50 mm. Therefore, measurements in situ, i.e. directly in orbit, are urgently needed to make it possible to describe the Earth’s flying garbage dump with sufficient reliability in the first place. After critically weighing up the alternatives, ESA has turned its attention to a possible large-area detector based on the successful ADEO deorbit sails from HPS. If the sail membranes are now equipped with acoustic sensors and cameras on board, it will be possible to measure the dust flow in the required size range. The name of the project: SAILOR – Sail Array for Impact Logging in Orbit.

The spacecraft consists of two large detector surfaces 100 cm apart. The two sails have an exposed surface area of 25 m2; in the ADEO program, they are the main actors of the large dragsail versions under the name ADEO-L. The membranes are around 10 μm thick and are held in position by extendable cross booms. The booms are stowed together with the sail membranes during launch and deployed in orbit. The deployment module in which booms and sails are integrated, consists of a deploying mechanism with a motor that pushes the boom arms outwards. A system of multiple cameras is mounted to a separate boom to document the holes created on the inner surface of both sail membranes. Acoustic sensors are attached to the sails to detect an impact in real time. The interaction of SAILOR’s technical equipment will ultimately allow the density, speed and trajectory of the small debris to be determined.

The ambitious ESA project SAILOR is currently in the transition from Phase A to Phase B1, which will also include the construction of breadboard models of the spacecraft and its electronics as well as the associated test programs. It also involves these steps:

Overall, the specifications of the project in this phase should lead to a positive decision at the ESA Ministerial Council meeting in Bremen in November 2025 on the continuation of a three-year mission at an altitude of 850 km to be launched in 2031/2032. The industrial team proposes a small precursor CubeSat mission, called OPTIMIST after this type of sailboat, to test the sensor technology using an approx. 10 m2 membrane as early as 2027/2028 as risk mitigation for the full-scale mission.

The industrial structure behind SAILOR also stands for this. This is because C3S, a leading Hungarian aerospace company, is acting as prime contractor for an ESA project of this kind for the first time, drawing on the expertise of ADEO inventor HPS GmbH as a subcontractor for the deployable membrane subsystem. C3S is also planning work shares for HPS in Romania. HPS CEO Ernst K. Pfeiffer: “The great enthusiasm with which we have taken on our role in this project rests on three pillars: firstly, it is existentially important for the space industry as a whole; secondly, it is an opportunity for us as HPS to impressively demonstrate the versatility of the ADEO technology from our company; and thirdly, we consider it eminently important in Europe that the industrial talents of Hungary and Romania are finally brought to light in an appropriate way, and that in a joint mission. We at HPS are delighted to be working under the project management of C3S.”

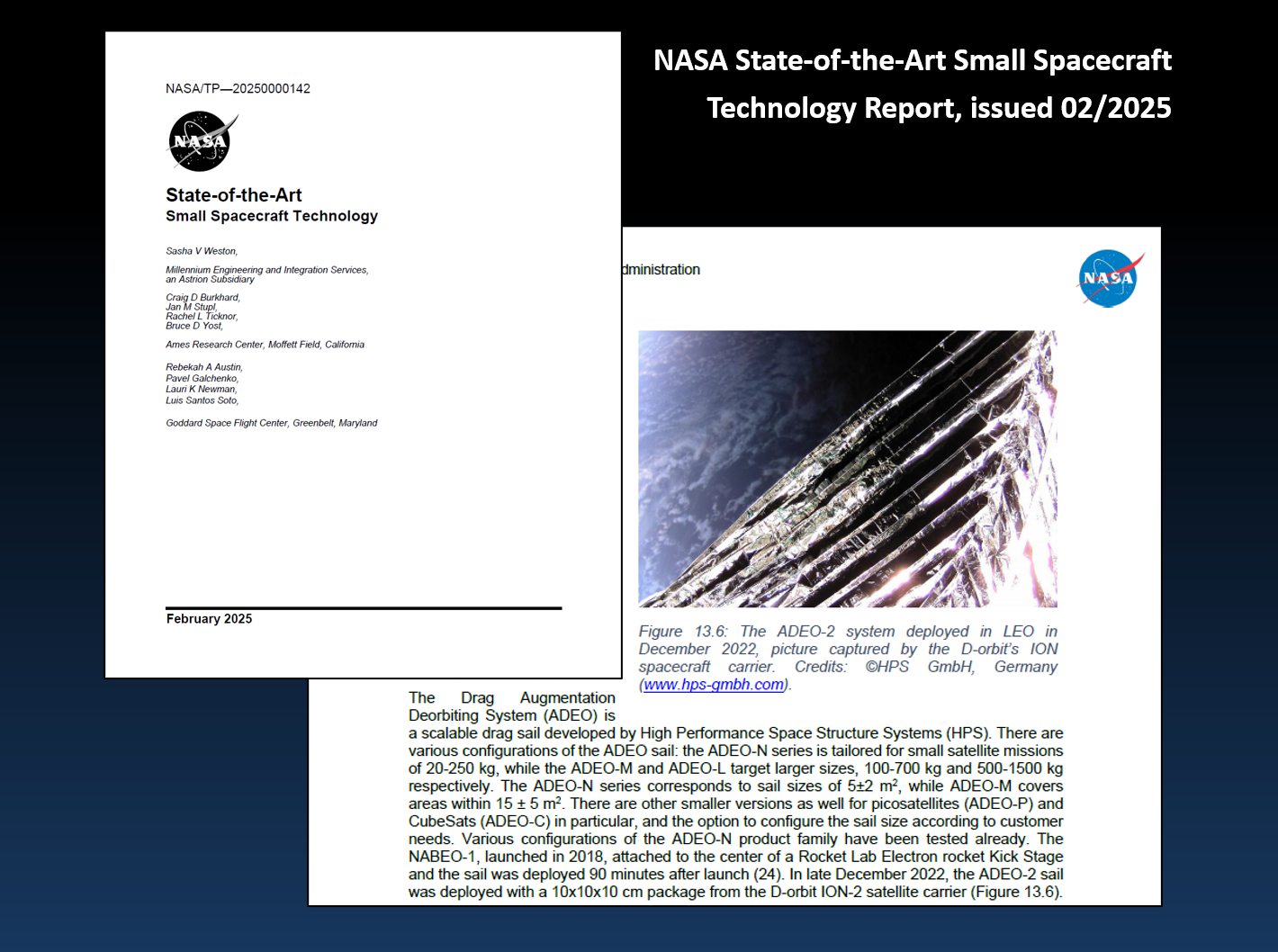

HPS with ADEO product family: top position in NASA’s technology report extended

March 2025

A year ago, the deorbit module from HPS took its place at the top of the podium of the most important technology achievements according to NASA. This was because ADEO already had everything that the American space agency considered crucial for success at the time: top values up to TRL9, scalability and proven flight heritage. Exactly one year later: ADEO, now supplemented in the technology report by the presentation of the bestsellers ADEO-Cube and ADEO-Pico, maintains its position both against numerous Dragsail competitors and against other passive deorbit technologies.

HPS CEO Ernst K. Pfeiffer comments: “With ADEO, we are surfing at the top of the wave worldwide that we have created ourselves with this technology over many years of R&D – often with significant co-financing by ESA and DLR plus considerable company resources. And we are actually delighted with every attempt by other companies to establish deorbit sails on the market: The bigger they make the wave, the higher our product family sails on its crest.”

ADEO – Space Heritage

January 2025

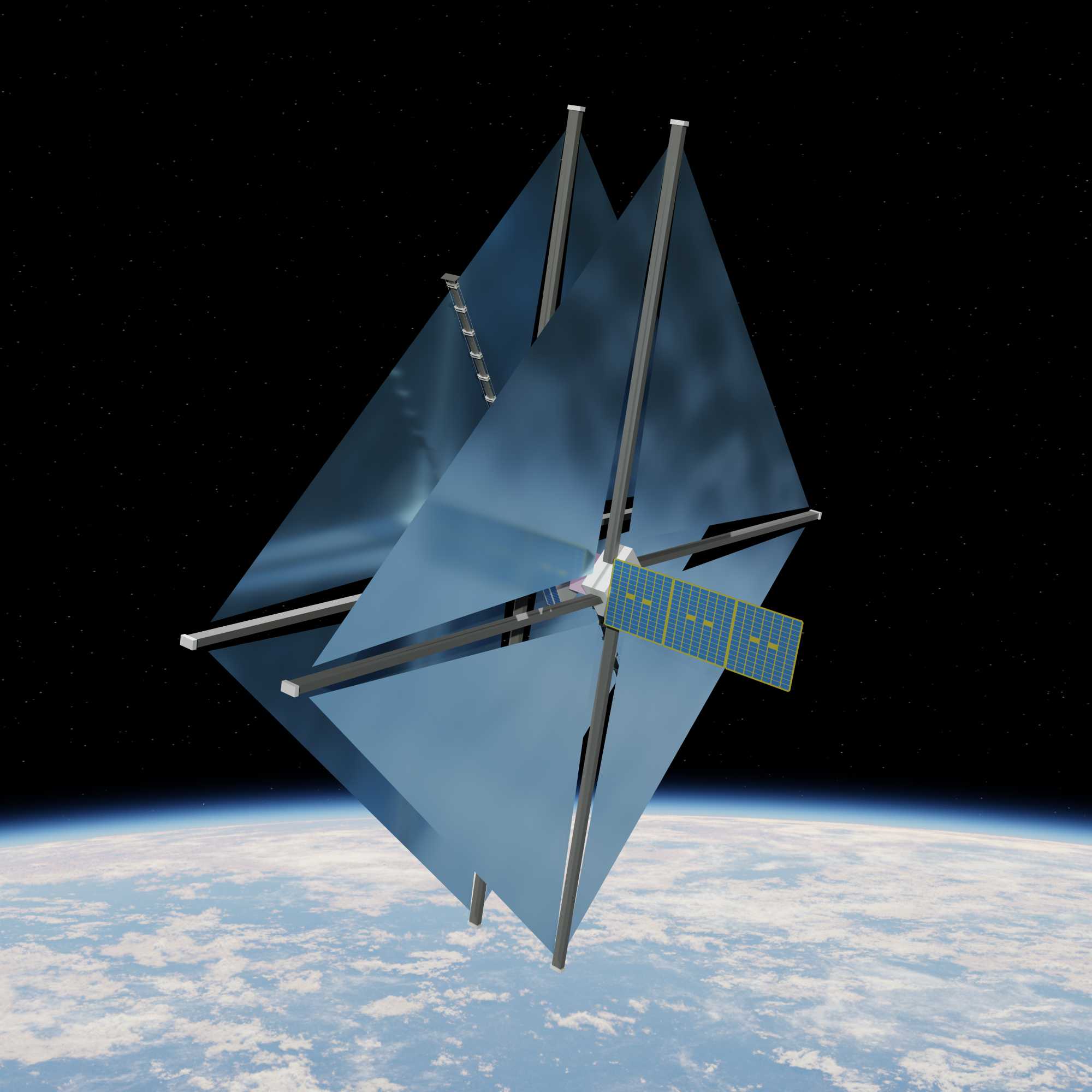

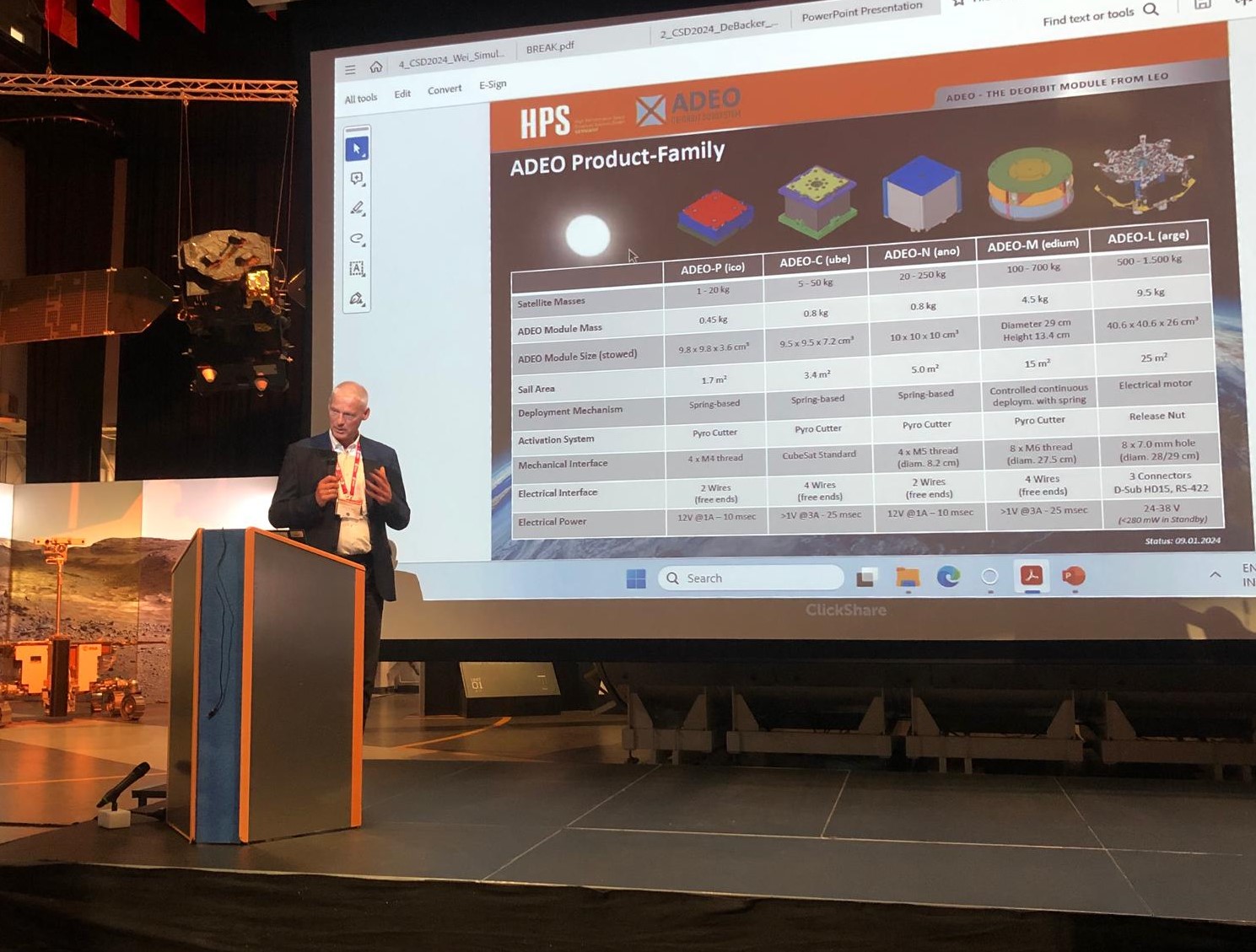

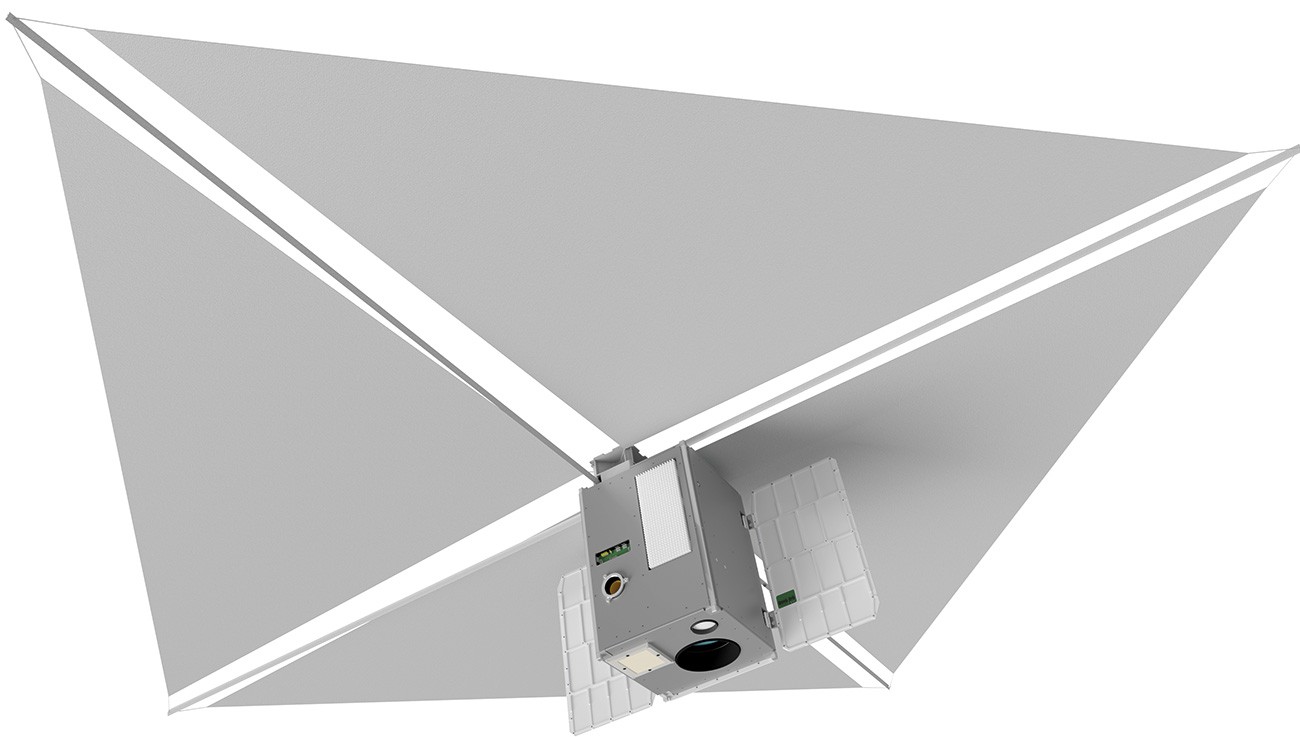

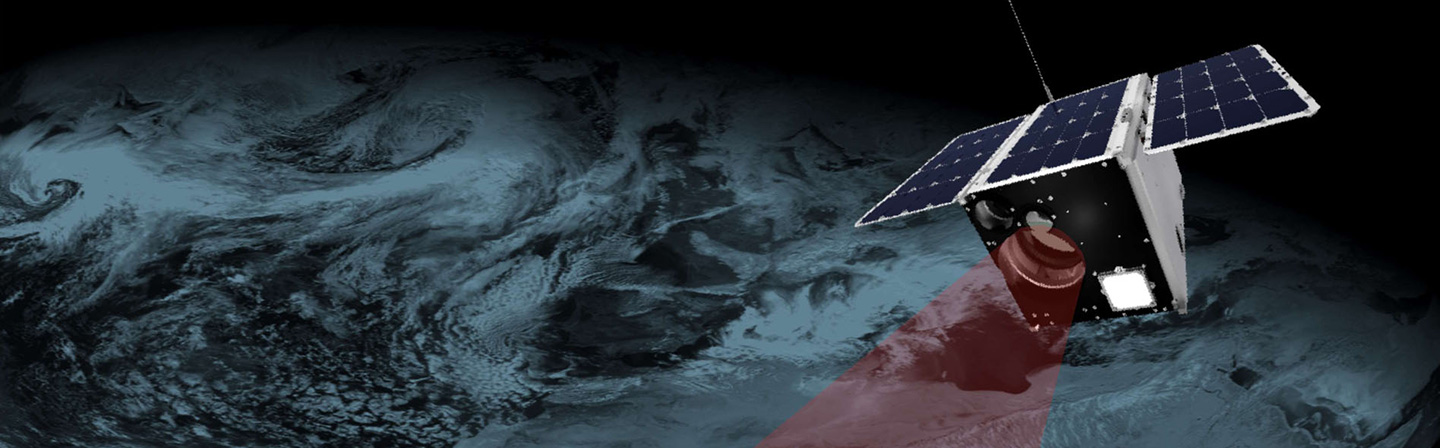

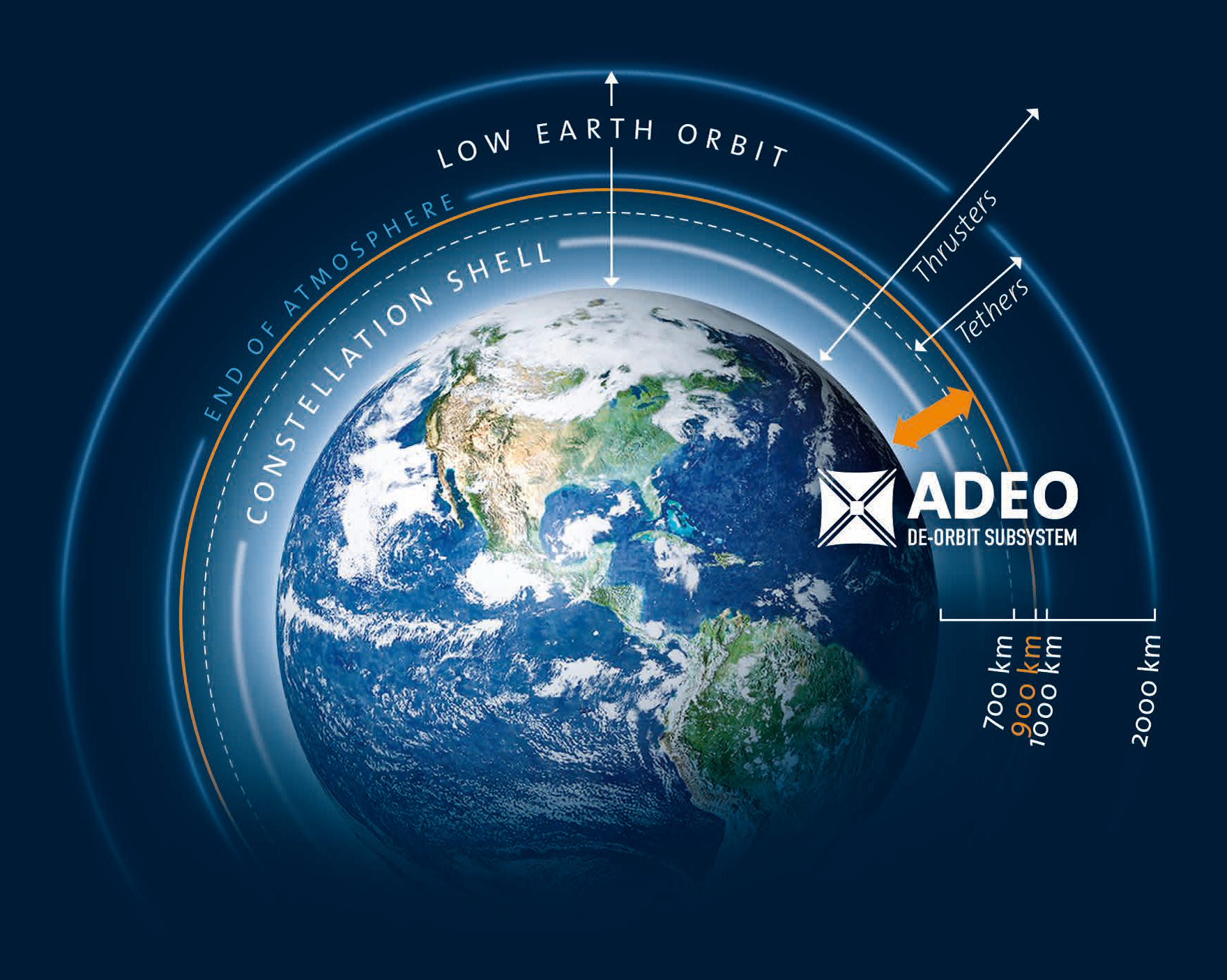

ADEO (Atmospheric Deorbit Sail Module) is the name for an entire product family of drag sails for satellites from the German space company HPS, Munich. They accelerate the disposal of satellites from space to a period of less than five years and thus fulfill the prerequisite for the satellite to receive approval for launch into space in the first place.

The sail is scalable and available in many variants from series production. ADEO-N is tailored to small satellite missions of 20-250 kg, while the ADEO-M and ADEO-L series are designed for larger missions of 100-700 kg and 500-1500 kg respectively. The ADEO-N series corresponds to a sail size of 5±2 m2, while ADEO-M covers areas of 15 ± 5 m2 and ADEO-L 25 m2 and more. However, smaller versions have also been available for a year, especially for cubesats, e.g. an ADEO-P for 1U-6U satellites (1-20 kg) and an ADEO-C for larger cubesats (5-50 kg). A total of five versions are currently available to order, all of which reliably dispose of satellites from LEO – including those from higher MEO orbits when combined with satellite’s onboard propulsion – within the required time frame. A corresponding configurator for selecting the perfectly suitable ADEO module is available for individual mission calculation (ADEO Online Configurator).

Now there is a short film about the production and testing of the product family, as well as ADEO’s heritage story:

Based on over ten years of development, HPS has successfully completed a series of missions up to “full burn” and has thus firmly established itself at the top of deorbit technologies at qualification level TRL 9.

2018: ADEO-N1 (“NABEO”) was launched on a Rocket Lab Electron rocket kick stage back in 2018, with Peter Beck himself (CEO RocketLab) even personally handling the sail. On this flight, the sail was unfurled just 90 minutes after the launch. Visual ground observations confirmed the successfully deployed sail and its performance.

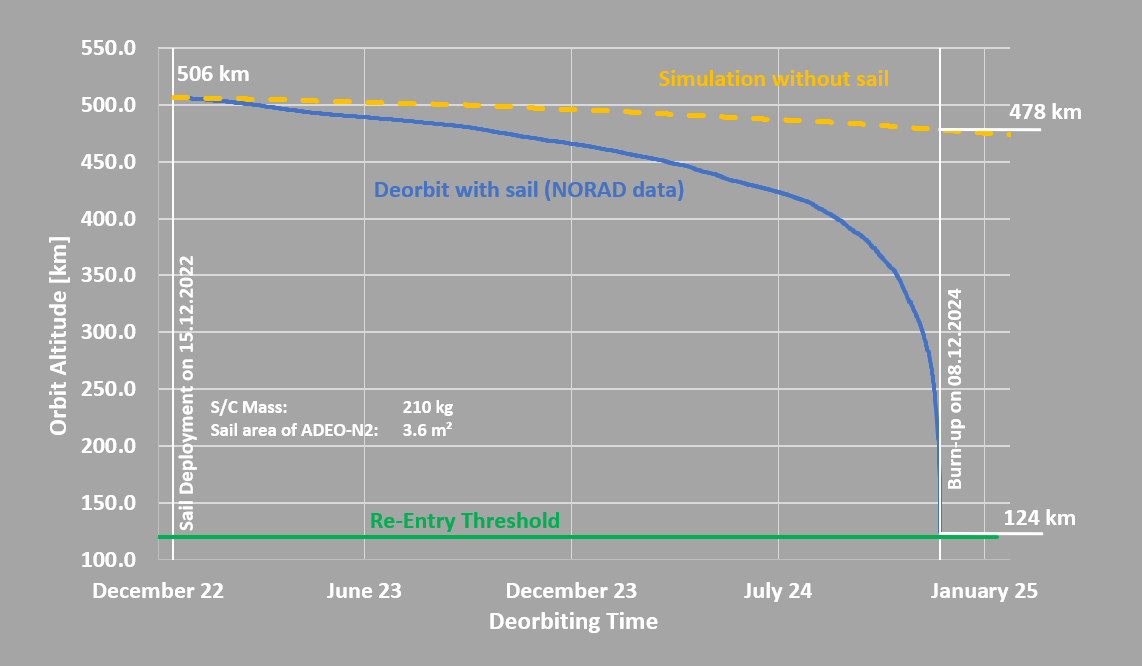

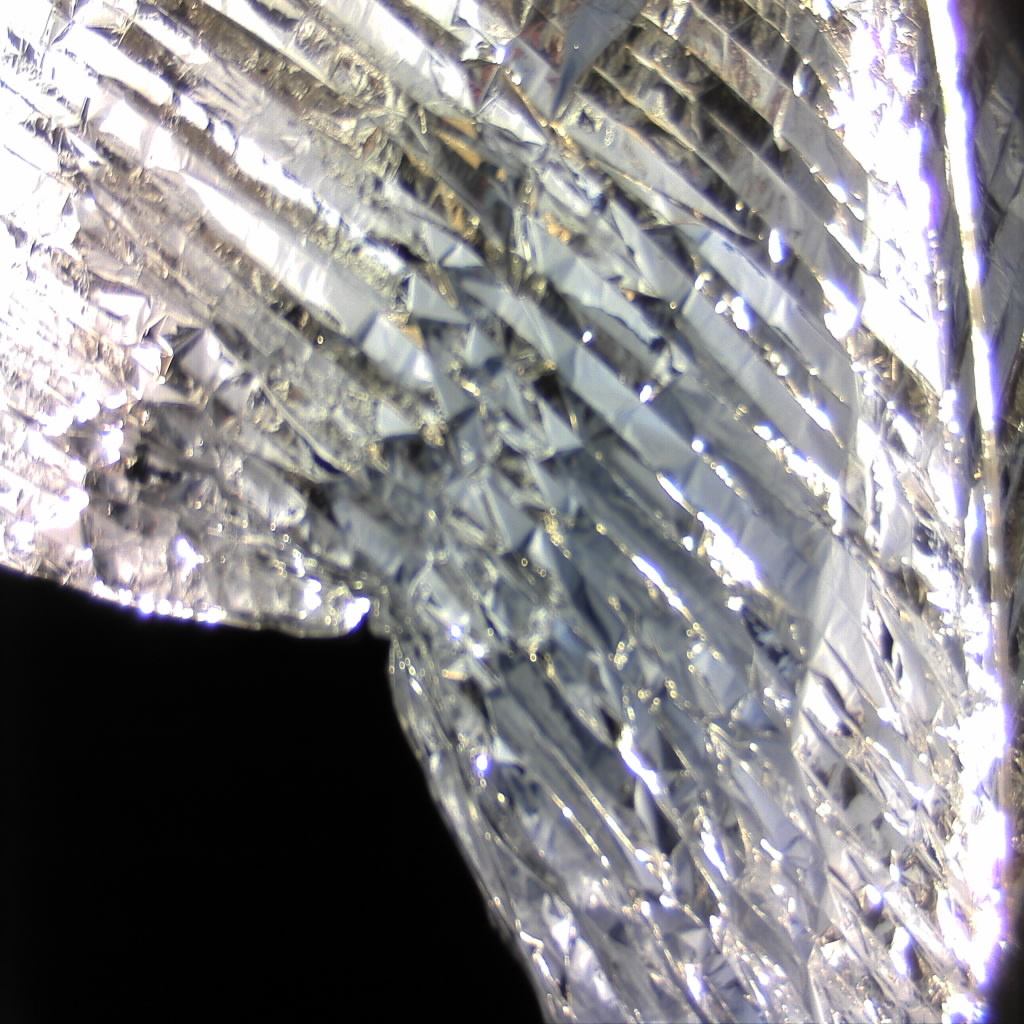

2021: In June 2021, ADEO-N2 (“Show me your Wings”) was launched into space by the spacecraft carrier ION-003 of the Italian launch service provider D-Orbit, as part of SpaceX’s Transporter-2 mission. The successful deployment of the sail in December 2022 was recorded by the ION carrier’s on-board camera. The integrity of the sail after one year in orbit was confirmed, again by means of the onboard camera. On December 8, 2024, HPS received confirmation that ADEO-N2 had completed its mission with deployment of the dragsail at 506 km orbit altitude in a record time of just two years after the 210 kg satellite’s “end-of-business” with fireworks of success at 120 km orbit altitude, beating international rules and regulations by three full years.

Even NASA ranks the ADEO module from HPS as the number one automatic passive deorbit technology in view of the qualification and Flight Heritage.

ADEO is now a bestseller not only with European institutions and companies, but also in the fully commercial markets of the USA and Canada.

Highest qualification levels, proven reliability and flight heritage combined with scalability, availability and attractive pricing make the ADEO product family a highly visible beacon in the global field of deorbit systems for all satellites that must comply with the new 5-year deorbit requirement to obtain launch authorization.

Click here for the latest clip about ADEO

————————-

Video: © HPS GmbH, Munich, Germany, www.hps-gmbh.com

Production: Daniela Creutz, www.bluecirceproductions.com

————————-

WILD RIDE mission ends with fireworks of success for deorbit sail ADEO-N2

Three days ago, on December 8, 2024, HPS received confirmation that ADEO-N2 completed its mission with launch in 2021 and end-of-business with deployment of the dragsail at 506 km orbit altitude in December 2022 in a record time of only two years with a firework of success, beating international rules and regulations by three full years. This is further proof of the success of the German ADEO model, which is manufactured in series production by the German world market leader HPS for all sizes of LEO satellites in five ADEO versions. ADEO fulfils the “5-year rule” already issued by several states and organizations for obtaining launch and operating permits for satellites, and with “Wild Ride” this has now even been verified in orbit by precisely tracking the deorbit curve until the satellite burns up completely at an orbital altitude of approx. 127 km (see image).

About the mission:

On June 30, 2021, D-Orbit, a leading company in the space logistics and orbital transportation industry from Italy, announced the successful launch of another ION Satellite Carrier (ION SCV 003), its proprietary orbital transport vehicle. It lifted off at 9:31 p.m. CEST on June 30, 2021 atop a SpaceX Falcon 9 rocket from Space Launch Complex 40 (SLC-40) at Cape Canaveral Space Force Station (CCSFS), Florida. That same day, 60 minutes after launch, the vehicle was successfully placed into a 500 km high Sun Synchronous Orbit (SSO).

ION Satellite Carrier is a space transporter developed, manufactured and operated by D-Orbit. ION is capable of accommodating multiple satellites, transporting them into space, performing orbital maneuvers and precisely releasing them into dedicated orbital positions.

At the end of the so-called WILD RIDE mission, the ION SCV 003, weighing 210 kg at the time, entered the deorbit phase on December 15,2022 with the deployment of ADEO-N2 (effective sail size 3.6 m2, christened “Show me your Wings”) entered the deorbit phase and began testing the world’s first precise functional in-situ verification of a dragsail, with official “end of flight” on 08.12.2024 [source: NORAD], i.e. within exactly 2 years in a completely natural way and without exhaust gases from any propulsion system. Without sails, SCV-003’s deorbit would have taken twice to three times as long.

About ADEO:

ADEO-N is a 1U-sized deorbit sail module developed by the German space company HPS, in cooperation with several companies and institutions (e.g. DLR and Fraunhofer), co-funded by the ESA-GSTP program, the German national technology program, and the Bavarian technology program. In accordance with the new rules, ADEO ensures the removal of end-of-life satellites from LEO within a maximum of 5 years.

November 2024

HPS and EXOLAUNCH: Making Space Clean Again

HPS is happy to join forces with the Germany-based Exolaunch and is fully engaged to support customers of Exolaunch by enabling this very special and successful NewSpace-launch service provider to grant priority access to the delivery schedule of flight-proven ADEO* deorbit sails which are currently in high demand.

EXOLAUNCH’s COO Jeanne Allarie and HPS’s CEO Ernst Pfeiffer signed an Agreement on Space Tech Expo 2024 in Bremen in a great joint spirit (see pictures) the ambitious endeavour of

See for the respective EXOLAUNCH announcement

(* ADEO-modules are needed to allow a satellite deorbit after its “End-of-Business” within five years; satellites without this or any kind of deorbit accelerator do not get clearance for launch anymore.)

November 2024

German space agency chief Dr. Walther Pelzer and DLR delegation focus on visit to HPS Group

During the traditional DLR delegation round on the opening day of the Space Tech Expo in Bremen, the head of the German Space Agency at DLR, Dr. Walther Pelzer, focused his attention on SMEs in the German space industry. Special attention was paid to the innovation forge HPS. And it was represented in groups: with HPS Germany (Munich), HPS Romania (Bucharest) and the joint venture company HPtex (Münchberg, Germany).

With reference to pioneering antenna projects such as HERA and EUCLID, company boss Ernst K. Pfeiffer emphasized the leading position Germany has gained in special antennas for space missions. HPS is also positioning itself as a leader in the commercial sector with the successful ADEO braking sail project, which ensures compliance with the new 5-year rule for satellite deorbiting and thus keeps the satellites ready for launch.

In his role as spokesman for German space SMEs, Ernst Pfeiffer also took this opportunity to emphasize the enormous importance of the DLR and ESA’s capability-enhancing technology programmes for SMEs as the innovation backbone of the industry. According to Pfeiffer, the precise promotion of the technological capabilities of SMEs via dedicated competition areas reserved for SMEs is irreplaceable.

Live demonstrations, e.g. of a functional model of the ADEO brake sail or a scaled model of a deployable large antenna reflector, supplemented by product demonstrations from HPS-Romania (e.g. radiator) and from HPtex’s MESH production (e.g. Ka-band mesh sample for use in the Copernicus mission CIMR) rounded off the visit program.

October 2024

Clean Space Days der ESA im Oktober: ADEO aus dem Hause HPS im Fokus

In 2024, the ESA’s Clean Space Team once again invited participants to the continuation of the past Clean Space Days.

The four-day event will focus on progress in the areas of eco-design, zero debris and in-orbit maintenance.

The calendar of presentations in 2024 will highlight these topics, among others:

While some presentations tended to highlight ideas and technical concepts in statu nascendi, HPS manager Frank Hoffmann presented the ADEO product family, which is already successful on the European and, more recently, North American markets: Deorbit sail technology for automatic self-disposal of the satellite at the end of the mission.

The ADEO system offers a suitably customized solution for every class of spacecraft, whether as a “Pico” (1-20 kg), “Cube” (5-50 kg), “Nano” (20-250 kg), “Medium” (100-700 kg) or even “Large” (500-1500 kg). To ensure that satellite manufacturers are supplied without delay, all orders are handled by HPS directly from series production wherever possible.

Due to the fact that the requirement to carry a suitable disposal system such as ADEO is a prerequisite for launch authorization for practically all satellites from October 2024, longer delivery times are possible and can be largely avoided by ordering early.

The Clean Space Days will come to an end at the end of the week, but the saying “after the event is before the event” also applies to this successful European space event.

Oktober 2024

HPS Prominently Present at the IAC in Milano

Participating in the International Astronautical Congress, IAC, has developed into a good tradition at HPS over many years. This year, the company will be represented by Ernst K. Pfeiffer, CEO, together with ADEO project manager Mrs. Dorittya Milankowitch from HPS Munich and Horatiu Gheorghe as IAC-contact point for HPS Bucharest with products like secondary structures, thermal hardware and purging equipment. The HPS-team will keep up full presence during all five days of this international event.

Special highlights will be the company presentations; they are going to take place on Friday, 18th, from 10.15 to 10.45 a.m., and also as part of the Company Slam at the booth of the German association BDLI on Tuesday from 13.15 to 13.45 p.m..

Focus of both presentations will be on the product family of the ADEO deorbit sailsystem for automatic disposal of satellites after their end of mission, serving the idea of clean space, sustainability and debris avoidance even from the beginning of the satellite´s journey.

Main products besides ADEO to be asked at our booth: reflector antennas, deployable antennas, large deployable reflector subsystems, mesh, thermal hardware, purging equipment. HPS will warmly welcome there all its customers from both worlds: classic and NewSpace. For a dedicated prearranged business meeting please send a message to Contact@hps-gmbh.com.

September 2024

ADEO Pico: The smallest dragsail gains a foothold in the largest market

Deorbit Technology from HPS

With the ink now drying under the contract for a PICO-class satellite deorbit device from the ADEO dragsail family of HPS, the Munich-based space technology company is now also setting foot on North American soil: After careful consideration of the alternatives, the Canadian company StarSpec Technologies decided in favor of the system for integration on their InspireSAT 12U ADCS MVP satellite, to be launched in 2026.

The ADEO-P was purchased at the beginning of July. The integration will be carried out by the experts in 2025. The satellite is planned to be launched in 2026 aboard a Falcon9 as part of the Transporter-17 SmallSat Rideshire mission from the Vandenburg Space Force Base in the USA. At the end of the mission, the dragsail will be deployed to a size of 1.4 m2 and automatically dispose of the satellite within the now obligatory period of less than five years. The satellite will burn up in the atmosphere without leaving any residue.

This initiative promotes StarSpec’s high precision space-qualified ADCS components, including sub-arcsecond precision star cameras, cogless reaction wheels, and ultra-high-bandwidth controllers, providing 100x the precision and imaging quality for LEO imaging satellite.

Jason Brown, Mechanical & Technology Lead, commented on the key factors leading to the selection of the ADEO-P for InspireSAT: “A primary mandate of InspireSAT is to provide high performance in-orbit capabilities in a way that does not compromise and strongly maintains the continued and future utility of LEO. We are delighted to have HPS, a proven high-tech specialist in the international space industry, at our side, allowing StarSpec Technologies to maintain its sustainable and orbit-conscious approach to space in a way that maintains focus on the successful demonstration of our transformative state-of-the-art ADCS. Thanks HPS!”

August 2024

HPS CEO: “Wishing my namesake a happy return home”

As a rule, the purpose of a satellite, be it scientific or commercial, is the focus of interest. However, there are also a few exceptions that confirm this rule. One of these is the recently launched flight of an inconspicuous 18-kilo box with a Falcon 9 from SpaceX to a low target orbit at an altitude of 510 kilometers. The name: ERNST – abbreviation for “Experimental Space Application of Nano-Satellite Technology”. Its mission: to use infrared detectors from space to detect where in the world civilian or military rockets are being launched as they fly over the earth based on the hot radiation of combustion gases – and which target they are probably aiming for. This type of technology has long been standard in the USA in the technical instruments for the nation’s fourth branch of the armed forces after the army, air force and navy, the “Space Forces”; in Europe, research in this area is still in its infancy by comparison, which is why the ERNST mission represents an important milestone for Germany.

This application-related research purpose of ERNST is still at a highly experimental early stage, but the renowned Fraunhofer Institute in Freiburg is relying on tried and tested principles to avoid space debris: a braking system with a deployable sail for accelerated return at the end of the approximately three-year mission is also on board. This is a version customized by the Fraunhofer Institute for theERNST mini-satellite. HPS collaborated with Fraunhofer on the sail almost ten years ago as part of a master’s thesis and provided support. HPS is now a pioneer of the technology and currently the world’s only commercial supplier of flight-tested automatic brake sails of the so-called ADEO family, with a total of 5 different product versions for all size classes of LEO satellites. ADEO braking sails are currently becoming standard equipment, because from fall 2024 at the latest, no satellite will be transported into space by the de facto monopoly provider SpaceX without such on-board technology for accelerated return under the new FCC regulations after the end of the mission.

“After a certain period of familiarization with the new legal situation, the run on ADEO brake sails is now in full swing. Customers in North America have also built up a great deal of trust in ADEO and HPS; the fact that HPS with ADEO occupies the lone top position in the NASA technology report on deorbit technologies is certainly helpful here. In this respect, we are naturally extremely pleased that, in addition to our commercial system on the market, we are now also securing further points for product trust and popularity through our collaboration with one of the world’s most famous German research institutes. That’s why, for once, I don’t see the operational research mission as the highlight here, but rather its end, and I wish my namesake a happy journey home,” comments Ernst K. Pfeiffer, CEO of HPS.

© Fraunhofer EMI

© Fraunhofer EMI

August 2024

ESA: 1 million for product innovation by HPS, AAC and DLR

ESA’s GSTP program is one of the European Space Agency’s most important instruments for promoting new technologies, particularly those generated by SMEs. The program also enjoys high priority in the overall ESA portfolio at the German space agency; the corresponding financial resources now also enable the launch of a new sub-program called “Product Initiative”. With the signing of the contract on August 7, 2024, ESA and HPS as the main contractor gave the go-ahead for the first technology project in this category.

It took just over six months from the idea to the signing of the contract; the funding amount is one million euros. The Munich-based space technology company HPS and its long-standing partner, Vienna-based Aerospace & Advanced Composites GmbH, are contributing 20 percent of their own funds, while the DLR Institute of Space Systems in Bremen is also on board on the research side. Over the next 24 months, highly innovative films (working name “ProFilm”) will be developed in various thicknesses and surface configurations and for large-area applications, which are characterized by two special features in particular:

In addition to use as thermal insulation for satellites, this also results in innovative applications as invisible brake sails as a further development of the HPS ADEO product range for deorbiting decommissioned satellites.

In this way, they serve four strategic goals of European space:

The ideas go as far as deployable structures that could make entire satellites invisible with ProFilm.

HPS CEO Ernst K. Pfeiffer is enthusiastic about the start of the project: “The innovation processes that have now been initiated will result in highly exciting products – the cooperation with our partners, DLR in the north and AAC GmbH in the south, alone is a guarantee of this. Above all, however, this premiere of ESA’s new GSTP sub-programme shows how quickly and effectively the European space agency can identify, accept and master technical challenges. This is exactly what European space travel needs, and this is exactly what innovation drivers from the ranks of SMEs need in particular.”

July 2024

ADEO deorbit sail system from HPS

Space-related technologies should be clean and sustainable, because only then access to space will remain possible for future generations. This topic, which is currently a top priority of space policy, has led to a number of technical solutions which are now available on the market, with the ADEO deorbit system from HPS leading the way. Being recognized even by NASA, the ADEO dragsails ensure already before launch that satellites will not turn into space debris at the „end-of-business“. Instead, they re-enter the Earth’s atmosphere.

The European Space Agency ESA, as well as its national counterpart DLR and the Bavarian Ministry of Economic Affairs, has consistently supported the twelve years of development of this product by HPS. The sharp increase in demand from customers, particularly in the CubeSat and SmallSat sector from Europe, but also from North America and even Asia, is driven by the simple fact that both ESA, for European launches, and the FCC, for American launches, now demand on-board systems to be able to deorbit a satellite in just 5 years instead of the previous 25 years. Also SpaceX confirms that no more satellites will be launched without complying to this requirement.

With the ADEO variants “Pico”, “Cube”, “Nano”, “Medium” and “Large”, HPS meets the market demand for all sizes of LEO satellites in orbits between 300 and 900 kilometers. All variants are already in production, with manufacturing at the HPS production sites in Munich (Germany) and Bucharest (Romania) which are closely working together. Nevertheless, HPS and the technical ADEO experts at ESA have identified a number of optimization and expansion opportunities in order to urgently increase the pace of the series production and in response to the increasing price pressure of the New Space scene. The company is now raising the required funds for the implementation of these opportunities in the short term, using co-financing of 1.2 million euros signed by ESA on June 28, 2024.

ESA-Director Dietmar Pilz for Technology, Engineering and Quality in a videocon on July 1st: „my best wishes for this important technology development.“

HPS CEO Ernst K. Pfeiffer: “As a company, we are very pleased about the trust and continuous support from the European Space Agency, and therefore indirectly also from the German Ministry of Economic Affairs. However, this is at least as much a reason for joy for all those who, thanks to its technology programs such as GSTP, would like to see Europe in a leading role in the development of components for space technology and -transport, especially in the commercially so important LEO and MEO supplier market.

ESA’s priorities here are not only clear, but are also being consistently implemented. One milestone was the recent signing of the Zero Debris Charter in Berlin. The upcoming optimization of series production and the enhancement of our ADEO product portfolio, while maintaining the same level of quality and reliability, will effectively help to face the upcoming peaks in global orders, including those received very late, and thus still enable the launch of these satellites. We shareholders see our own funds, in the 7-digit range over the years, on the one hand as an investment in a strong future for HPS, and on the other hand as our moral obligation to make a contribution to the sustainable use of space.”

June 2024

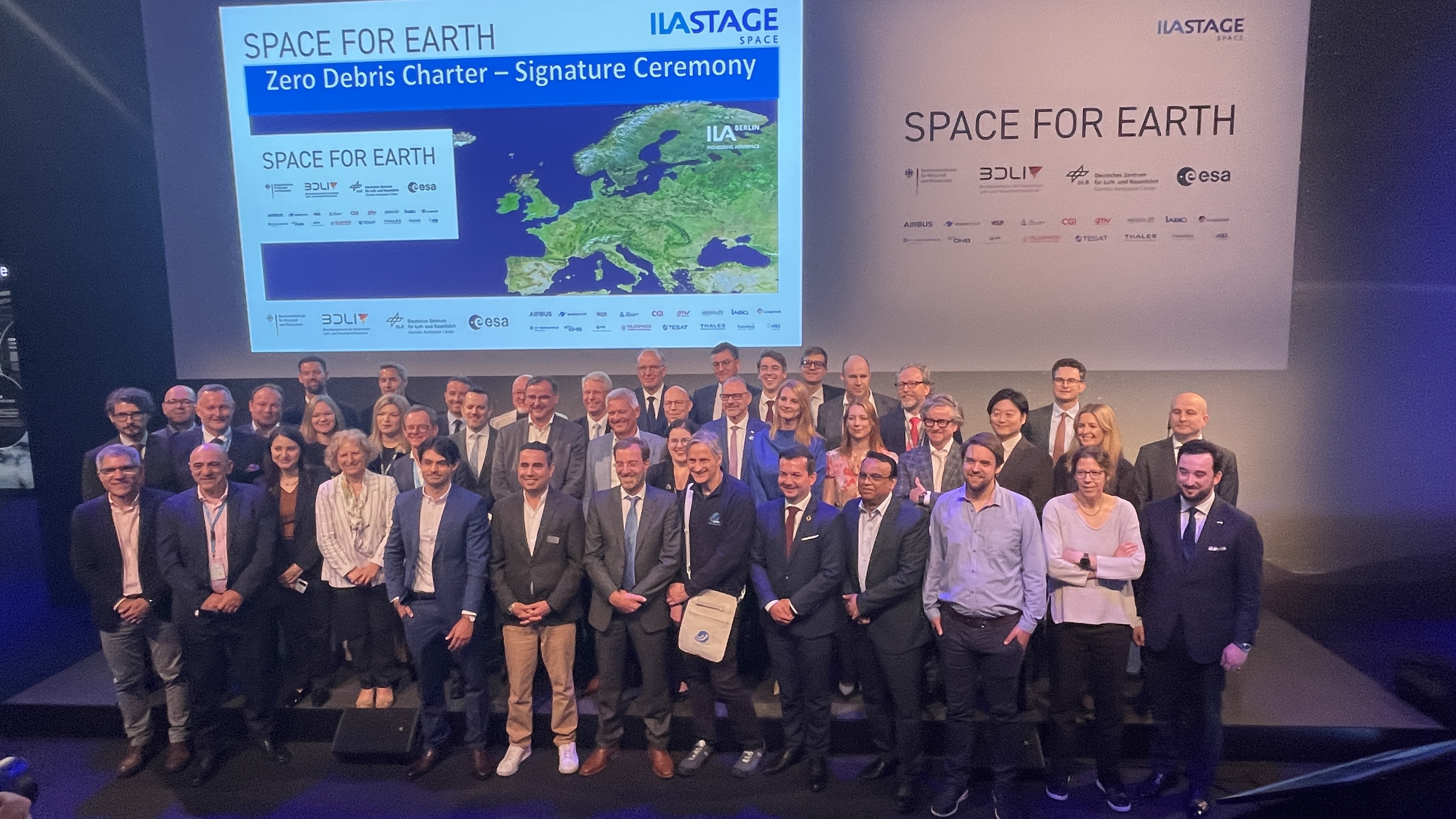

ESA Leads the Way: Rapid Implementation of the Zero Debris Charter

Sustainability in space travel has also been an issue for the European Space Agency ESA for years. However, only a few months passed between the decision to adopt a Zero Debris Charter and its implementation.

Keynote speaker ESA Director General Josef Aschbacher also saw this as a sign that the time is finally ripe for concrete steps instead of pure symbolism, especially as ESA itself has provided significant impetus for the development of the two main technologies on the way to “Zero Debris”: firstly, ways of removing scrap from space, but above all, equipping satellites with deorbit technology from the outset so that no more waste is produced after the end of the mission.

ADEO Drag Sail: The Key to Sustainable Spaceflight

The ADEO brake sail, which is now available as an entire product family for all sizes of LEO satellites from HPS series production, stands for this. In addition to grants and support from ESA, DLR and Bavaria, HPS CEO Ernst K. Pfeiffer also invested a lot of the company’s own money in the project, always firmly convinced that the hour of ADEO would come sooner or later – and if a little later, then all the more powerfully.

It was exactly the same when, in mid-2023, the ESA set the new rule of a deorbit maximum of 5 years for ESA-funded missions instead of the previous 25 years, and, accordingly, LEO satellites without ADEO (or similar) will no longer be launched at all from October 2024, as SpaceX, for example, makes clear in its conditions of carriage in accordance with FCC regulations.

Historic Moment: 12 Nations Sign the Zero Debris Charter

The Charter was signed in Brussels on May 22 by 12 countries, including Germany. Since then, over 100 organizations, companies and entrepreneurs have been waiting for their cue to sign.

The ILA 2024 marks a very important stage on this path towards the sustainability of European space travel and sets an example for companies on other continents.

May 2024

Update on ADEO´s Performance

After 487 days of approachflight towards Earth, ADEO-N2 on the ION SCV 3 test satellite continues to sail on a record course without even a scratch: the current position has been reached in a threefold shorter time of the ADEO deorbit compared to the classic missions, whose data are subject to the prediction algorithms.

Expected touchdown at the edge of the Earth’s atmosphere: April 2025.

This is reported by the two mission managers, D-Orbit, Rome (satellite) and HPS, Munich (brake sail).

February 2024

Since its inception, the U.S. space agency NASA has been the primary driver of progress in aerospace technology. NASA’s Scientific and Technical Information (STI) program plays a key role in ensuring that NASA maintains this important role. Its Technical Reports Server contains one of the largest collections of aerospace science STI in the world, including “Technical Publications” on critical research and achievements of lasting value.

Focus on deorbit technologies

The aim of the latest publication, published in February 2024, on groundbreaking technologies, particularly in the field of small satellites, is, among other things, to present the world’s leading deorbit technologies, which can be used to technically implement the new regulation on the disposal of LEO satellites, which has been sharply limited from 25 to 5 years in both the USA and Europe. In its evaluation criteria for technologies, NASA is primarily guided by the TRL standard of the respective products and also pays great attention to the scalability achieved.

ADEO has it all: top values up to TRL-9, scalability and flight successes

According to NASA, the deployable brake sail system ADEO from HPS occupies the leading position on the global market in the category of passive deorbit systems. This is because ADEO not only offers technological maturity up to the peak value of TRL-9, but also a successful flight heritage and is also prepared for equipping various small satellite formats thanks to the HPS series production of an entire product family. This broad protection of HPS’s leading position with ADEO has been widely recognized by NASA – despite the fact that it is a competitor with several projects in this field:

“The Drag Augmentation Deorbiting System (ADEO) is a drag sail developed by the German company High Performance Space Structure Systems (HPS). The sail is scalable and HPS has already launched a number of missions with different configurations up to TRL 9. The ADEO-N series is tailored for small satellite missions of 20-250 kg, while the ADEO-M and ADEO-L series are designed for larger missions of 100-700 kg and 500-1500 kg respectively. The ADEO-N series corresponds to a sail size of 5±2 m2, while ADEO-M covers areas of 15 ± 5 m2. There are also smaller versions, especially for picosatellites (ADEO-P) and CubeSats (ADEO-C), and the possibility to configure the sail size according to customer requirements. Various missions have already tested the ADEO-N product family. The NABEO-1 was launched on a Rocket Lab Electron rocket kick stage in 2018. The sail was deployed just 90 minutes after launch. There was a problem measuring whether the drag sail was initially deployed, but visual ground observations confirmed successful deployment and performance. At the end of December 2022, the ADEO-N2 sail was launched into space by the ION-2 spacecraft carrier of the Italian launch service provider D-Orbit. The successful deployment was recorded by the ION carrier’s on-board camera.”

ADEO – Deorbit technology as a prerequisite for launch authorization

With this presentation in one of the most important technology documentations of the US space agency NASA, HPS with ADEO becomes a highly visible beacon in the worldwide field of passive deorbit systems for all satellites that have to comply with the new 5-year deorbit requirement in order to be approved for launch by American or European launchers

Dezember 2023

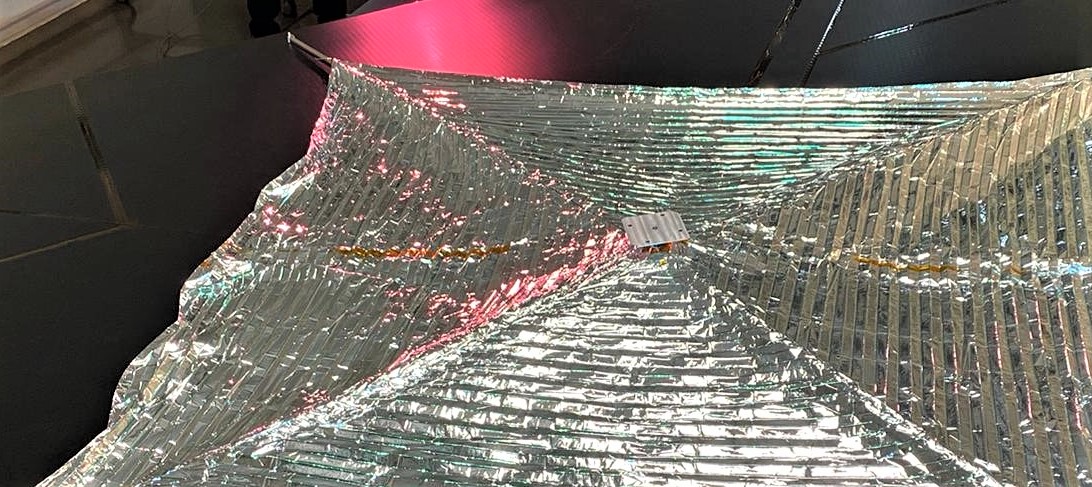

HPS completes the ADEO sail fleet with its first largest version under the version named L1. Its 25 square meters of sail area unfolded successfully deployed on Monday, 4th of December 2023 in a final ground test after a complete completed PFM qualification campaign. This included vibration tests in all axes as well as tests under thermal vacuum, including hot and cold firing tests (tests to verify the deployment release mechanisms under extreme temperatures). The tests were carried out under responsibility of HPS Munich at the facilities of the DLR Institute of Space Systems in Bremen – a prime example of cooperation between industry and research & development. This final and most important test enjoyed great interest from the media (including SAT1, RTL, NTV, DPA) covering the 20-minute deflation process and interviewing the enthusiastic project team of HPS and DLR. Links to the articles and television videos can be found HERE.

This test is also a success of ESA’s GSTP program, which significantly supported the development of ADEO-L1 financially and technically. Technology programs in general are essential for independent SMEs in the space industry and their products on the way to market readiness and worldwide series sales.

The ADEO brake sails deploy after the end of the satellite’s mission and brace themselves against the resistance of the atmosphere that still prevails in orbits up to an altitude of just under one thousand kilometers. This deployment immediately leads to a drastic reduction of the speed of the satellite and the entire package sets off on its accelerated descent towards the earth’s atmosphere, where it then burns up in the frictional heat of up to two thousand degrees Celsius. The entire return process takes even significantly less time than the latest guidelines prescribe. Until recently, the process could take up to twenty-five years, while it must now be completed within five years. And, to ensure that operators follow the rules, launch service providers such as SpaceX no longer even take satellites into space if they are not equipped with the appropriate return technology from the outset.

The Munich-based space-tech company HPS had this development in mind more than ten years ago, when no one else was really thinking about ways to avoid space debris. With great support from the space agencies ESA and DLR, the DLR institutes in Bremen and Braunschweig, the companies DSI, Bremen, and formerly HTS, Coswig, plus a seven-digit-investment of HPS, the company´s highly committed young team of experts has created an entire product family under the generic name ADEO, from the smallest versions ADEO-P (Pico), ADEO-C (Cube) and ADEO-N(Nano), ADEO-M (Medium) and the latest member of the group, ADEO-L (Large). The development master plan not only extends even further to possible ADEO variants with up to 100 square meters of braking surface, but also leaves enough room for derivatives with completely different applications, such as the monitoring of space debris smaller than1 cm directly in space.

In its largest flight-ready version to date, L1, ADEO has a take-off weight of 10 kg at dimensions of 43 cm x 43 cm x 25 cm; in contrast to the smaller versions, this unit also requires its own power supply for motor-controlled deployment of the masts and sails. ADEO-L1 generally fits perfectly on satellites up to the 1,500 kilo class.

In the first quarter of next year, ADEO-L1 will be integrated onto a satellite of the Belgian company Redwire for its first test flight at the end of 2024/beginning of 2025 as part of a EU program, while the versions ADEO-N1 and ADEO-N2 have already passed their baptism of fire in space. Approaching the fiery finale is currently ADEO-N2, deployed in December 2022. Since then, it has already lowered its satellite from an orbital altitude of 510 km to 460 kilometers in only 12 months without the aid of any fuel or attitude control. Expected “arrival” in a completely burnt-up state: mid2025 – and thus even around five times faster than without sails and twice as fast as prescribed.

ADEO-L1 will master this path of final in-orbit verification just as safely, company boss Dr.-Ing. Ernst K. Pfeiffer is certain. As with the other versions, it will then go straight into series production for which the company has special production facilities at its Munich and Bucharest sites.

November 2023

As part of the National Program for Space and Innovation and based on the decision of the Budget Committee in November 2022, the German Space Agency launched a competition for promising space innovations. The winner can expect a fully organized and financed demonstration flight with launch by 31.12.2025. On Thursday, 23 November 2023, the Federal Government’s Space Coordinator, Dr Anna Christmann, selected Munich-based space technology company HPS as the winner of the competition in the small satellite payload category with its ADEO-Cube space sail version at the 2023 Small Satellite Conference. The ADEO product family is designed as a series with different model types (Pico, Cube, Nano, Medium, Large), with which all satellites from the Cubesats to the larger representatives with 1.5 tons (class “M”) are automatically removed from low Earth orbit (LEO) and disposed of at the end of the mission. This so-called “deorbiting” with the ADEO braking sail not only fulfills, but even undercuts the maximum duration of 5 years that will apply from October 2024 instead of the 25-year guideline that has been in place since the 1960s. Quite simply, this means that no satellite will soon be accepted for launch without special on-board technology, such as the appropriate space sail from HPS’s ADEO series, if it cannot otherwise be legally disposed of. Since SpaceX, for example, as the leading launch service provider, will be introducing this rule from October 2024, it will apply to practically all future satellites, including those that are already in the design and manufacturing phase today.

As HPS CEO Ernst K.Pfeiffer, there is still only one alternative to ADEO, but it “is chemical, expensive and – in the case of a damaged satellite – inoperable”, the passionate aerospace engineer states about the market position of the ADEO space sail: “ADEO is currently the cheapest, most reliable and cleanest solution for legal deorbiting on the global market, available in all classes thanks to series production at HPS Bucharest and HPS Munich, and highly competitive in the hotly contested commercial market for satellite technology.We at HPS, especially our development team, are all very pleased that our sustainable technology has been recognized by the Small Satellite Competition at the highest level.”

November 2023

Initiated by ESA´s office for “Strategy and Transformation” a considerable group of European space companies, including HPS, got together in order to jointly draft and now implement this continent´s set of rules for sustainable use of space. HPS is one of the first companies to sign the document on November 7th, 2023. Though legally non-binding, the “Zero Debris Charter” aims at putting an end to the inconsiderate and irresponsible pollution of space with tech-junk. In detail, the Charter clearly names the following targets:

Ernst K. Pfeiffer, CEO of HPS at the signature ceremony: “In our days now space is rapidly developing into the most important resource for the implementation of new technologies shaping our future on Earth. All efforts to preserve space from the beginning are therefore nothing less than efforts to preserve the fundamental conditions of life and its prosperity for humankind´s generations to come.”

*For more see:

*https://esoc.esa.int/zero-debris-community-update

*https://www.esa.int/Space_Safety/Clean_Space/World-first_Zero_Debris_Charter_goes_live

*https://www.esa.int/Space_Safety/Clean_Space/ESA_s_Zero_Debris_approach

*https://www.esa.int/Space_Safety/Clean_Space/The_Zero_Debris_Charter

November 2023

Less than 36 months ago, they were regarded by many as nothing more than political empty phrases: the “Green Deal” of the EU Commission in Brussels and the “National Orbital Debris Implementation Plan” of the White House in Washington. Satellites continued to be launched into near- and far-Earth orbits with the prospect of becoming junk and endangering other missions for a quarter of a century after they finally burned up in the atmosphere. But that’s over now: With the adoption of the “Zero Debris Charter”, ESA has committed itself on November 7, 2023 to taking steps towards total avoidance of any space debris from 2030 at the latest, and even more concretely, namely already from October 2024, SpaceX, with over one hundred launches per year the world’s most important launch service, will no longer transport any payloads that are not equipped for their disposal within a maximum of 5 years after the end of mission operations. And as early as 2023, the U.S. FCC (“Federal Communications Commission”), as the supervisory authority for the allocation of radio frequencies, sentenced a satellite operator to a fine of $150,000 for prolonging the operation of his satellite with the propellant actually reserved for disposal, thus recklessly endangering all other missions in the vicinity. While the sum might make some people smile, the FCC has now put an end to all symbolism with its decision to no longer grant radio licenses to satellites without on-board technology for return (technical term: “deorbit”) within 5 years of the end of operations. Under the double threat of operation AND launch ban, practically all operators are forced to equip new satellites only with guaranteed reliable deorbit technology from now on.

This can be done with the on-board propulsion system using chemical propellants while shortening mission and profit, but even that does not work in case of satellite failure and is also comparatively expensive due to the need for constant control monitoring from the ground.

The alternative is called ADEO: from HPS (Munich and Bukarest) a space sail, self-deploying at the end of the mission, which automatically removes the satellite from space well below the specified deorbit times, is ideally suited as baseline-tech and emergency parachute. Already 36 million flight kilometers before the planned maneuver, the German specialist for orbit guidance and collision avoidance OKAPI:Orbits (Braunschweig) as a cooperation partner calculates the point for the descent without risk for other satellites. In addition, HPS partner number two, the Italian company AVIOSONIC, in constant liaison with the worldwide air traffic control stations, ensures via new ADEO-features highly accurate position conrol and spares aircrafts from hits by any satellite parts that may not have burned up.

The ADEO product family with officially attributed highest possible level of reliability (“TRL 9”) holds tailor-made solutions for all satellites from the tiny Pico- and Cube-Sat up to the 1.5 tonner and for all low-Earth orbits up to a distance of 900 kilometers from Earth. All ADEO lines are mass-produced by HPS, yet they feature adaptive design for special requirements that may arise from satellite design.

The prices of all ADEO models without exception are considerably lower than the expenditures required for deorbiting with chemically driven engines – apart from the fact that the safety of the deorbit of even these satellites – for example in the event of a system failure – can actually only be guaranteed by an ADEO system carried along as a backup.

For more detailed information on ADEO see: https://www.hps-gmbh.com/en/portfolio/adeo-angel-on-wings/

June 2023

When, after two, five or more years of operation, a satellite is supposed to leave its orbit and re-enter Earth, it’s a ride on the skyway to hell in two respects: first, for the satellite which is destined to burn up in the atmosphere, but also for other satellites as well as for an encounter with scrap parts that could hit it like unguided missiles – and produce even more junk. Satellites equipped with the ADEO braking sail from HPS are already in automatic descent mode. From now on, however, this can be upgraded by the Collision Avoidance system from industry-leading German startup OKAPI:Orbits. The company emerged as a spinoff from Braunschweig University of Technology in 2018 after over 40 years of intensive research. This Collision Avoidance System minimizes the collision risk during the de-orbit trajectory by figuring out the situation even ten days in advance. Appropriate maneuvers are also recommended for the satellite’s control system. This is made possible by the unique AI behind OKAPI:Orbits.

“Picture a distant view of 6.72 million kilometers of orbits on which about 10,000 satellites, 1,000,000 large and medium objects and 130,000,000 small ones exist that are not currently trackable. This is how complex computing operations is. Now, we should also take into account their velocity of 20,000 to 30,000 kilometers per hour. To any human sensibility, this is pure chaos, which the artificial intelligence behind our Collision Avoidance Software handles with aplomb,” says OKAPI’s company CEO Kristina Nikolaus.

Ernst K. Pfeiffer, CEO of HPS, a medium-sized innovation company, adds, “Our ADEO braking system not only performs the fastest possible passive descent even under adverse conditions – for example, when the satellite is already dead – it is also the deorbit solution with the largest safety reserve directly on board. Customers who don’t want to rely solely on their own software to control their satellites will find a unique safety architecture for the deorbit of almost all satellites with ADEO’s optional assistance systems for position tracking (Aviosonic) and optimal descent prediction (OKAPI:Orbits) at HPS.” ADEO is under discussion as a deorbit subsystem for the satellites of Europe’s coming constellation IRIS2 and “together with the features of Aviosonic and OKAPI:Orbits it levers the constellation to the most secure and sustainable one also after satellites’ nominal lifetime.”

During descent, the combination of all three technologies onboard the satellites will increase significantly the orbit determination and prediction, which is a unique advantage also for other satellites, constellations and stakeholders like owners, operators, and insurers.

June 2023

[Munich-Bucharest-Paris, June 12th, 2023] – HPS GmbH, a leading technology company specializing in cutting-edge solutions, is pleased to announce its membership in the Net Zero Space Initiative, an ambitious global movement dedicated to supporting sustainable practices and innovations in space.

The Net Zero Space Initiative brings together industry leaders, organizations, and experts from various sectors to collaborate on finding concrete solutions to combat space debris, thus preserving not only the economic and scientific benefits of outer space, but also its strategic potential in addressing urgent challenges such as climate change. By joining this esteemed network, HPS reaffirms its commitment to environmental stewardship and especially to a sustainable development of space infrastructures.

As a member of the Zero Space Initiative, HPS GmbH will actively contribute to the collective efforts aimed at developing sustainable technologies and practices across its operations. The company will leverage its expertise and its political as well as its industrial network to drive transformative change.

HPS drives advanced technology solutions like the world market leading deployable deorbit sail “ADEO” which enables quick decay of satellites until re-entry, reducing the risk of in-orbit collisions. By joining the Net Zero Space Initiative, the company aims to accelerate these efforts, collaborating with like-minded partners and leveraging collective knowledge to drive greater impact.

“We feel that as a part of the Net Zero Space Initiative we are with the right people,” said Dr. Ernst K. Pfeiffer, CEO of HPS. “At HPS, we believe that sustainability is both, a responsibility and an opportunity for innovation.

By collaborating with the Net Zero Space Initiative, we can amplify our efforts in developing and implementing sustainable solutions, contributing to a “greener” future in space and for our planet.”

As an advocate for sustainability, HPS GmbH Germany, as well as its affiliate HPS S.R.L. Romania, remain committed to driving positive change through its products, services, and operations. The company’s membership in the Net Zero Space Initiative represents a significant milestone in its sustainability journey.

May 2023

The ever-growing number of satellites orbiting Earth presents a significant challenge in terms of space debris management. As space agencies and private companies deploy increasing numbers of satellites, finding effective and sustainable solutions for their safe disposal has become paramount. In this regard, the ADEO Deorbit Sail, developed by HPS offers a groundbreaking technology that enables controlled and efficient satellite deorbiting for mitigating space debris and ensuring long-term sustainability in space. By harnessing the natural forces present in space, such as solar radiation pressure and atmospheric drag, the sail facilitates controlled reentry of satellites into Earth’s atmosphere at the end of their operational life.

ADEO has already reached ESA´s hightest level of maturity, TRL 9 and proven its reliability on a number of spaceflights; getting ready to serve Europe´s new constellation IRIS2 its NewSpace-team at HPS, Munich, take it even one step further and introduce the ADEO special “stealth” sail edition. While irritating reflections and view blocking effects of conventional constellations like Starlink cause a permanent nuisance to other users of space like astronomers during flight and deorbit, the constructors of Europe´s constellation IRIS2 are going can count on to receive from HPS an exclusive offer for a special version: the ADEO Stealth Sail –invisible, fully transparent and also available for most satellite types and operational orbits.

As HPS-CEO Ernst K. Pfeiffer explains: “Our ADEO deorbit system already presents numerous benefits and applications in satellite end-of-life management like cost- & mass-effective and sustainable deorbiting, compliance with current and future Space Debris Mitigation Guidelines, flexibility and adaptability. Now, with the special stealth version for dedicated to the architects of Europe´s IRIS2 constellation we take the decisive step to let Europe set yet another standard in space sustainability”.

Mai 2022

(Munich-Milano, May 10th, 2023). At testified TRL-9 and with solid flight heritage the sail system “ADEO” already is the leading device for quickly deorbiting almost all satellites, thus preventing spacecrafts after their end of mission from becoming as well as producing new space junk for years to come. Because it is a sail, it does not produce any pollution itself, chemical or otherwise, and because this very sail will be in its next version also transparent and absolutely non-reflective, it does not cause any irritations to any space observer on earth. Munich based spacetech innovator HPS, a medium sized company with a subsidiary in Romania and a total headcount of 80, has invested – together with several institutional and industrial partners – 12 years of constant development and qualifying into ADEO, and is now ready to take yet another giant leap by joining innovative forces with Aviosonic Space Tech, Milan/Italy.

Aviosonic Space Tech, born in 2015, owns the patented DeCAS system (Debris Collision Alert System) for in-orbit/de-orbit tracking and re-entry footprint prediction of space vehicles. DeCAS is a 1U mm system which always maintains a constant link with the ground operation center allowing precise information on the satellite position, aliong with the calculation of the re-entry footprint in real time, with the aim of collision avoidance between satellites, satellites and aircrafts as well as to alert government agencies. The technical characteristics and modularity allow DeCAS to be installed on any space vehicle, offering different services depending on the mission requirements. DeCAS, which took part in different space missions, provides a unique service for satellite tracking, decommissioning and re-entry prediction in real-time.

Prof. Piermarco Martegani, CEO of Aviosonic Space Tech says:”The integration between DeCAS and ADEO allows the creation of a unique product on the market capable of strongly implementing the safety of space operations both during orbital and decommissioning re-entry phses, even in the event of failure of the hosting satellite. This safety information is also needed by the Air Traffic Management System. The collaboration between Aviosonic Space Tech and HPS is the demonstration that in order to guarantee safety during space operations, an international cooperation between SMEs is necessary.”

HPS-CEO Ernst K. Pfeiffer shows bulletproof confidence in the future of ADEO on the world market and emphasizes: “ADEO has all the facts on its side: first, all space industry badly needs a deorbit device like ADEO, since the faster the sail opens free orbit positions, the longer we can keep space as a sustainable surrounding. And, from second to infinite: ADEO combines TRL9 and flight heritage, offers a comprehensive range of models, beats economically as well as ecologically any other type of deorbit device, also it is already in serial production at HPS. And now we even join forces with the two outstanding innovators in their fields, and others will join, underlining once again what´s at the core of ADEO: 100 percent European, 100 percent SME, 100 percent sustainability in space – and exactly what Europe wants for Iris2.”

Contact for further information:

HPS: Dr. Daniel Stelzl, stelzl@hps-gmbh.com

Aviosonic: Prof. Piermarco Martegani, Piermarco.Martegani@aviosonic.it

ADEO Dossier: German: (https://www.hps-gmbh.com/tag/adeo/)

ADEO Dossier: English: (https://www.hps-gmbh.com/en/tag/adeo-en/)

Video: https://youtu.be/pUeSZzdn_6c

April 2023

After FCC, SpaceX, and ESA now also the three German startups racing for the smaller launchers` pole position in the commercial market made it clear that tickets to space will be available only to satellites prepared to be able to deorbit quickly after service.

The companies made their points recently in statements to the German space magazine “Raumfahrt Concret”.

For more details see: RCI-Newsletter-1-2023.pdf (hps-gmbh.com)

Ernst K. Pfeiffer, CEO of HPS, the German spacetech company that has developed ADEO to become the number 1 deorbit device for spacecrafts on the market, comments: “While we witness many cases of exorbitant differences in opinions when it comes to principles the space industry should follow, it is with great relief that we see this case ruled by unanimous voices echoing the new green spirit of deorbit from everywhere.”

January 2023

Already in the heat of last summer, HPS in Munich was preparing for the third mission of the innovative space brake sail ADEO-N, which unfolds automatically at the end of the mission and drives “its” satellite into the atmosphere to burn up. This technology avoids the formation of new space debris already on the ground and finally makes space missions sustainable.

The ION Satellite Carrier with ADEO-N3 with its sail area of 5sqm has been on board a Falcon 9 since the picture book start on January, 31, 2023 from spaceport Vandenberg, California, now on the way to the target orbit at 270 to 500 km altitude at 53 degrees inclination. Probably by the end of 2023 ADEO-N3 will then, as on previous flights – including one with ION also on Falcon 9 – deploy the braking parachute and remove its ION Satellite Carrier from orbit without leaving any residue many times faster than usual. With the flight heritage accumulated by then, the mature ADEO system heralds a “green” space age. Because at least for European missions or missions from Europe, there will – in all probability – no longer be any more launches without deorbit tech on board: The Green Deal of the EU will then also apply to “clean-green missions” in space.

On the current flight, ADEO-N3 acts as another verification of maturity for HPS. D-Orbit and HPS already captured what will happen high above the earth during a nominal mission as historical testimony on video during the last flight:

https://www.linkedin.com/feed/update/urn:li:activity:7021106640993021952

Video is free for publication