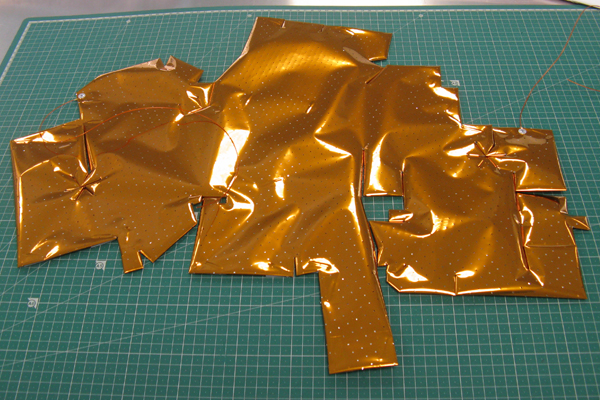

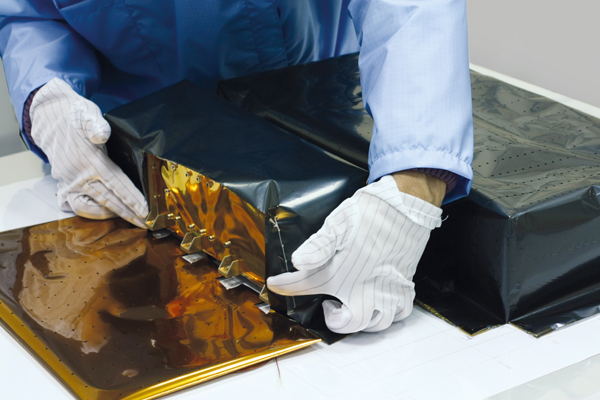

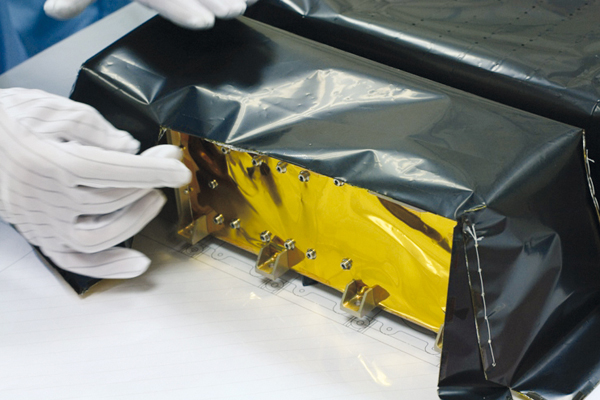

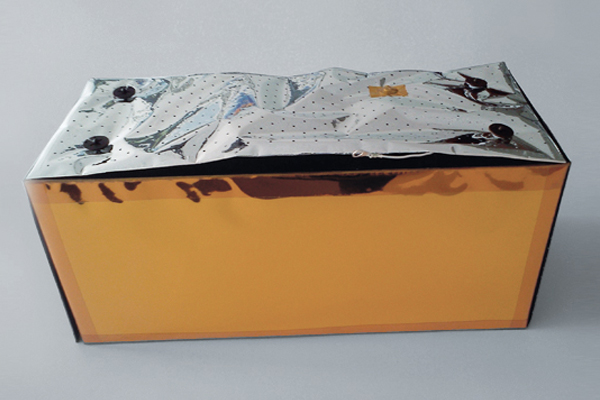

Multilayer Insulation (MLI)

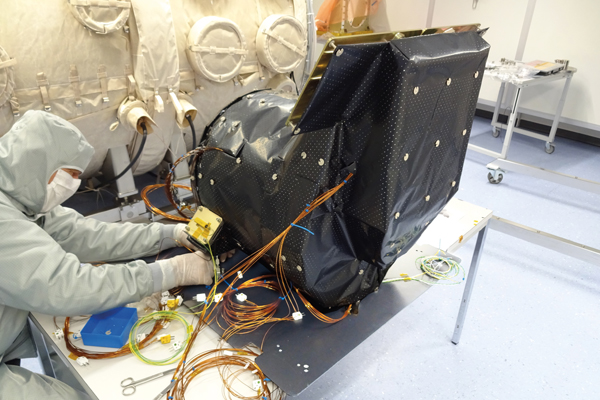

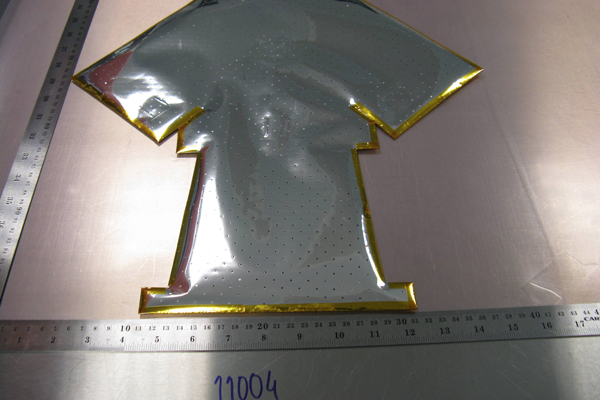

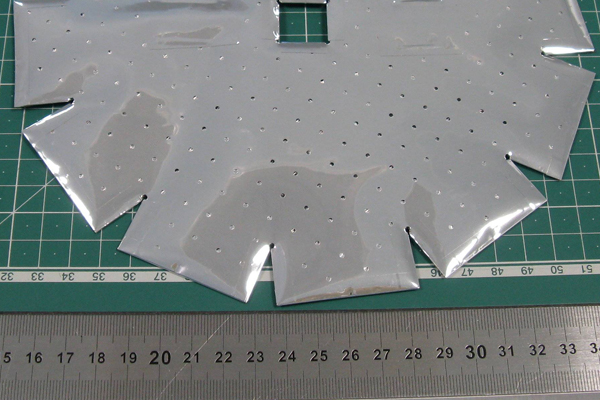

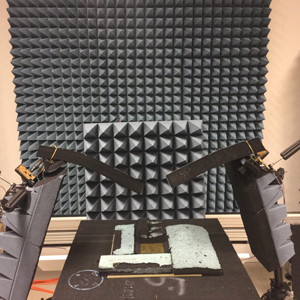

As one stop provider HPS delivers tailor-made multilayer-insulations (MLI) of all sizes and any degree of complexity: thermal design, definition of layer architecture, CAD-design, cutting, edge-finishing, grounding, characterization of performance and acceptance testing.

In addition, HPS-teams from Germany are available day or night to integrate the finished blankets to the flight hardware: efficiency, flexibility and speed “on demand”.

Engineering as well as management, system-engineering and final integration onto the flight hardware is offered by HPS Germany whereas the production is performed by HPS´s former daughter company FHP-Portugal. This is an advantage also when the question of georeturn plays a significant role in the whole project setup. With its perfect combination of engineeringresources and on the basis of highly modern cleanroom manufacturing capacities MLI made by HPS have conquered a steady growing market share.

further information

for manufacturing pictures click here.

Contact:

For further information please contact our chief engineer.

References:

→ Success Trajectory

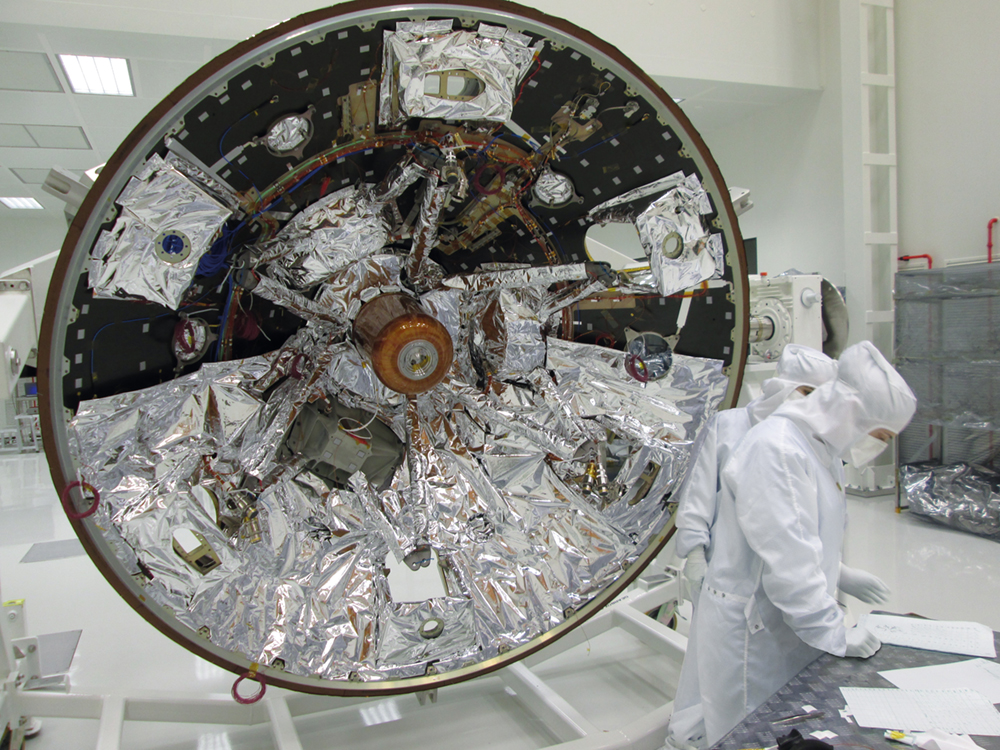

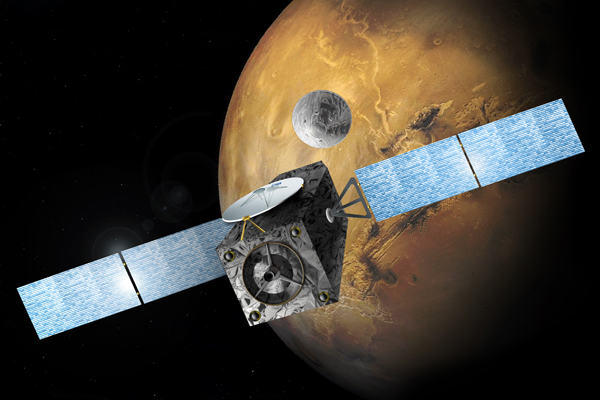

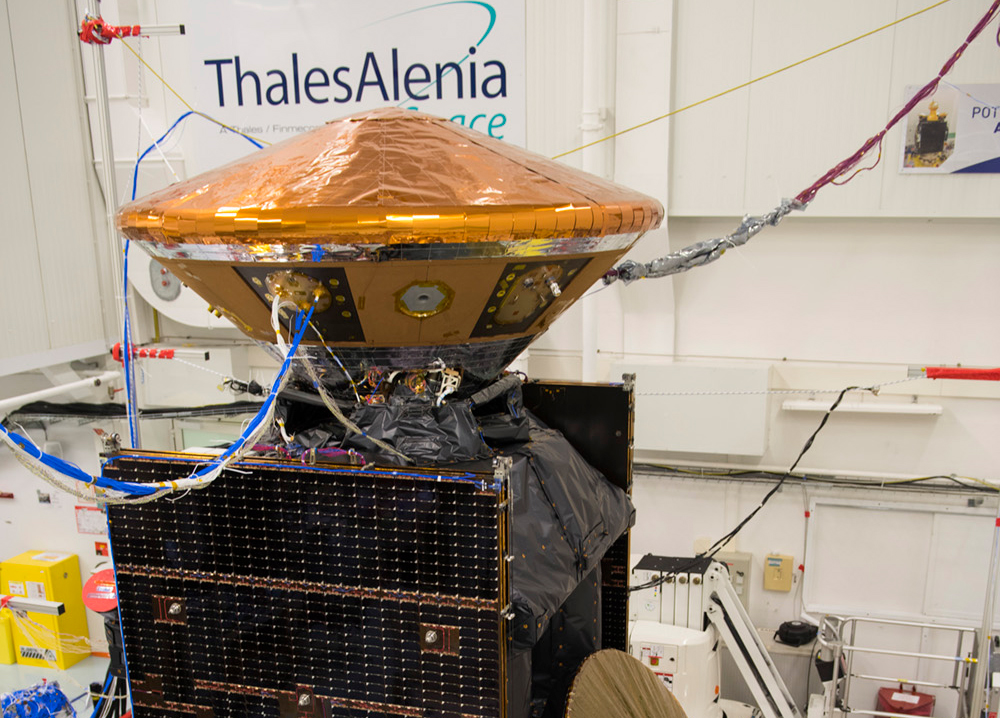

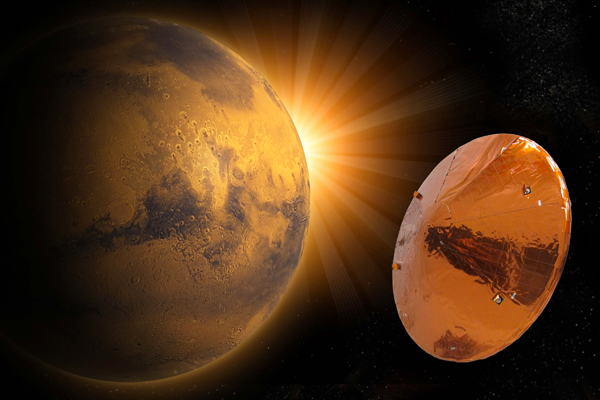

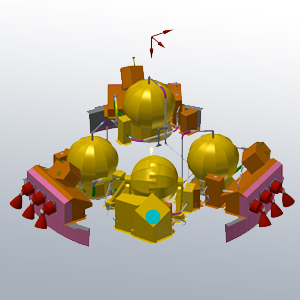

Spacecraft & Planetary Mission MLI

Reference project examples:

- ExoMars 2016-EDM

- EUCLID SSH

Features:

- MLI for complete satellites or planetary spacecrafts

- External & internal MLI for spacecraft engineered to meet

- Customer requirements for each part

- Thermal protection of complex shapes e.g. pipes and tanks

- Large blankets up to 3 m² possible

- Compliance with planetery protection and bioburden requirements

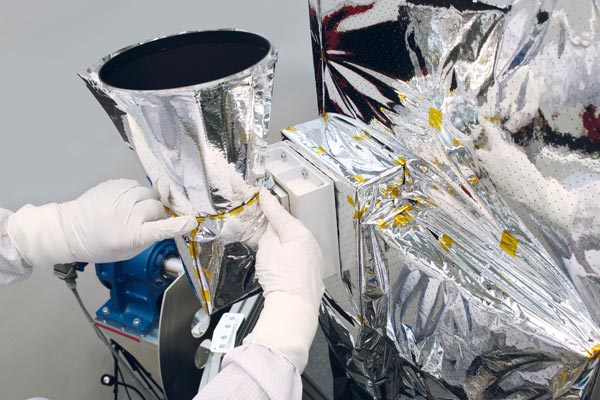

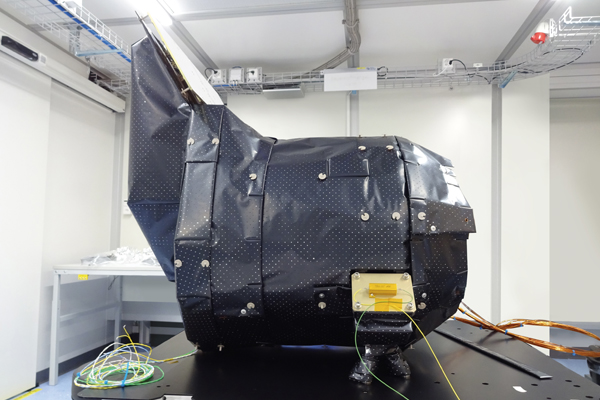

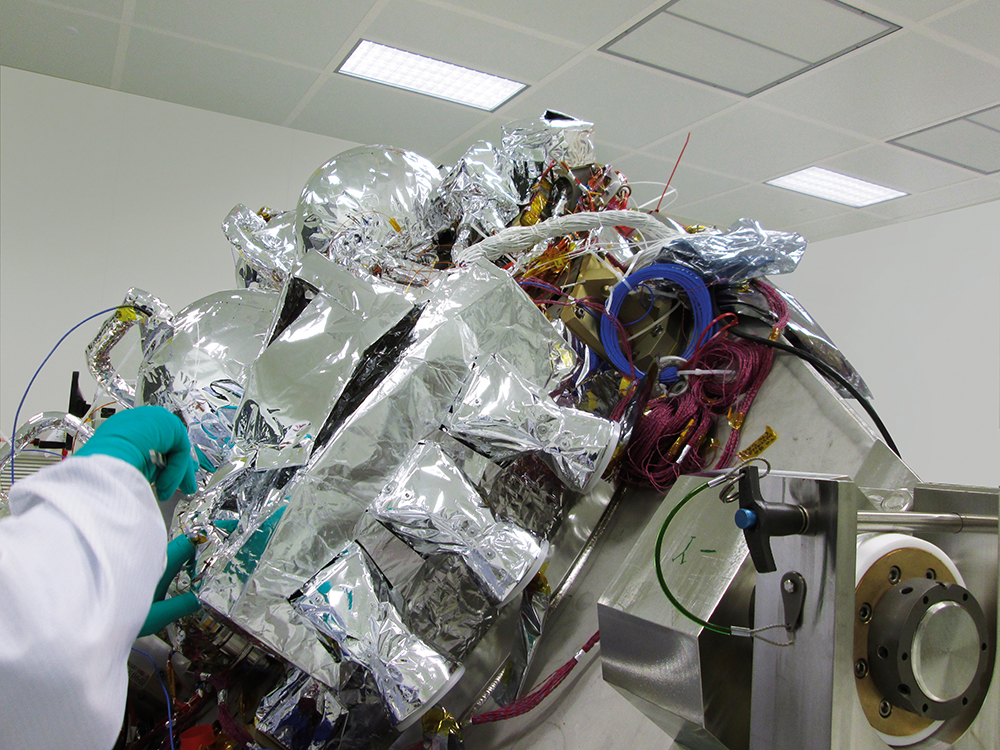

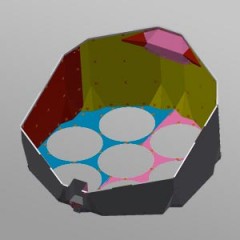

Space Telescope MLI

Reference project examples:

- eROSITA

- CHEOPS

- SENTINEL 4

Features:

- MLI close to sensitive hardware e.g. optical, IR, UV or X-ray mirrors

-

Engineered venting paths avoid contamination of sensitive hardware

-

Large blankets up to 3 m. possible

-

High cleanliness manufacturing in class 1.000 cleanroom

-

Maximum cleanliness up to class 100 possible for smaller parts

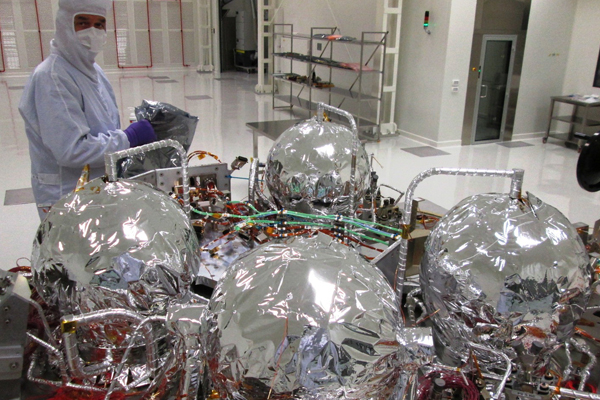

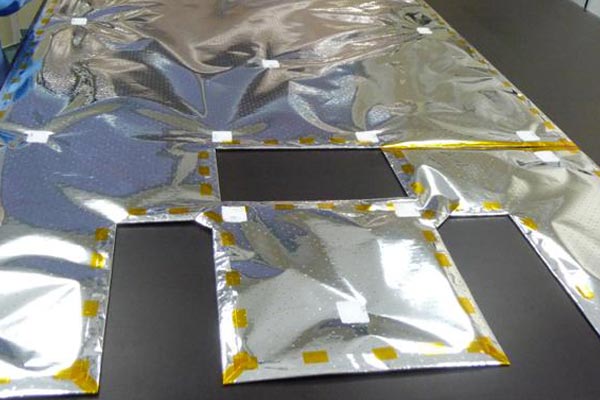

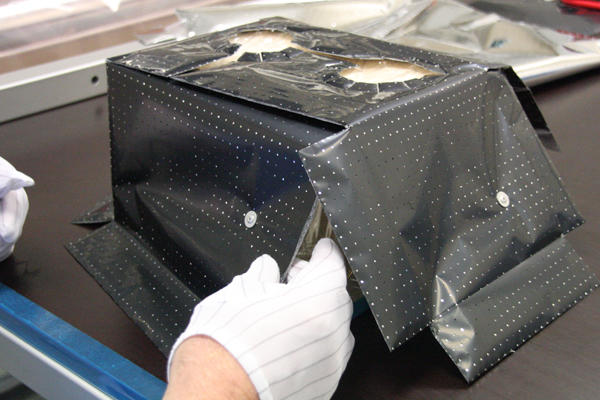

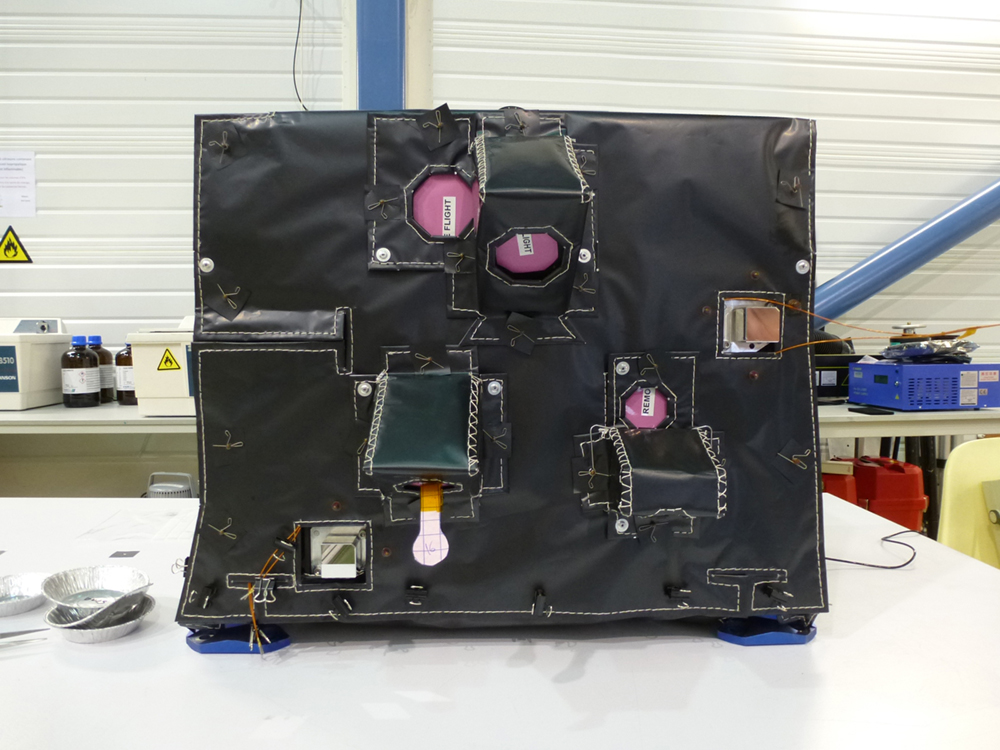

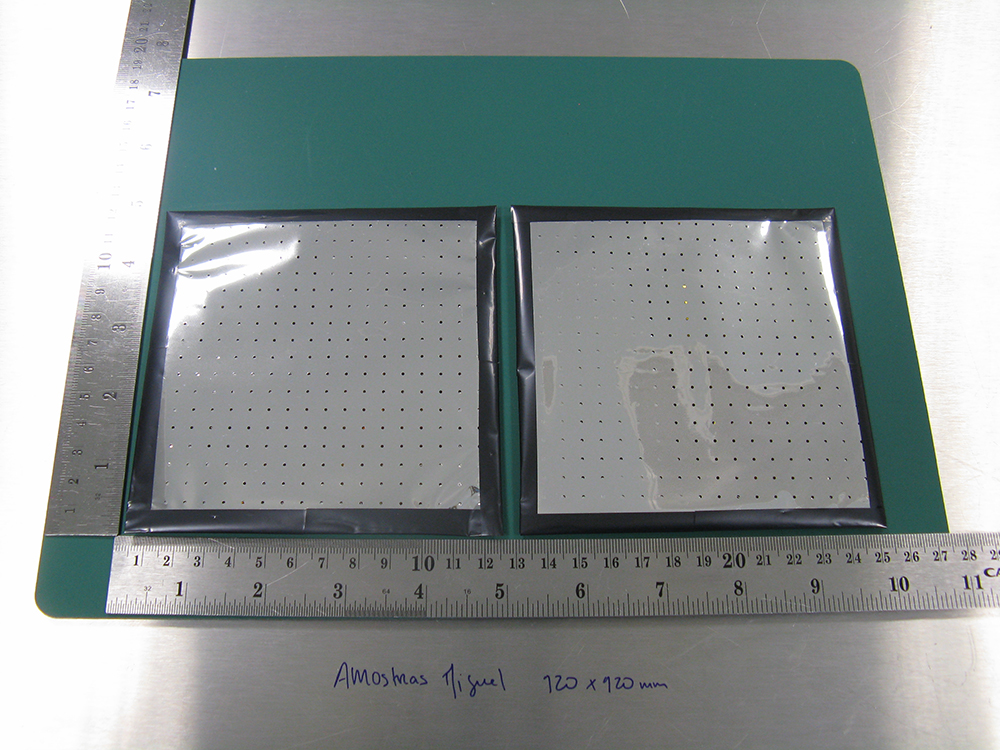

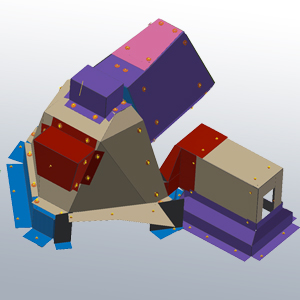

Instrument & Equipment MLI

Reference project examples:

- CASSIS on ExoMars

- EnMAP FAD

- Grace-FO LRI

Features:

- MLI for any type of instrument or equipment

- Small blankets down to 50 cm² possible

- MLI layup for instruments & equipment engineered to meet customer requirements for each single area

- Thermal protection of complex shapes e.g. support struts, apertures, mechanisms

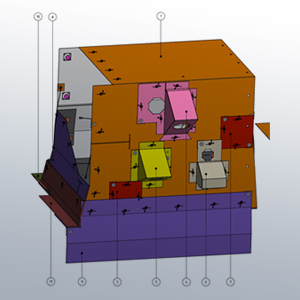

High Temperature MLI

Reference project examples:

- ExoMars 2016-NOMAD

- ExoMars 2016-Thrusters

Features:

- High temperature MLI for temperatures > 120°C

- Verification of Temperaturresistance

- Use of tape mitigated by sewing MLI blankets

- MLI layup engineered to meet customer requirements

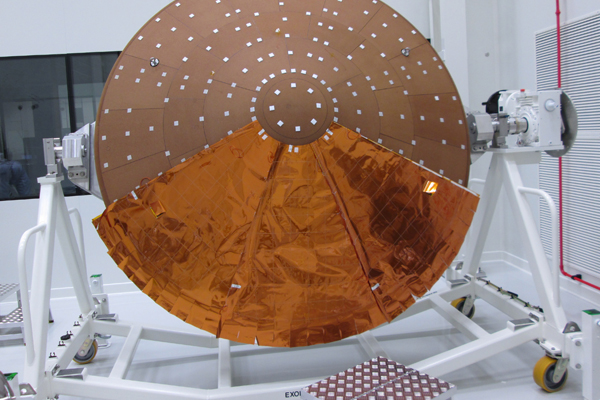

Antenna-MLI & Sunshields

Reference project example:

- MLI for Ka-band reflector on Heinrich Herz

- MLI for Ka-band reflector on EUCLID

- Sunshield for Antenna on Heinrich Hertz

- MLI for large deployable reflector subsystem LEA

Features:

- Sunshields for reflector antennas and other antennas

- Procurement of standard sunshield raw material

- Tailoring of sunshield to minimize RF performance losses