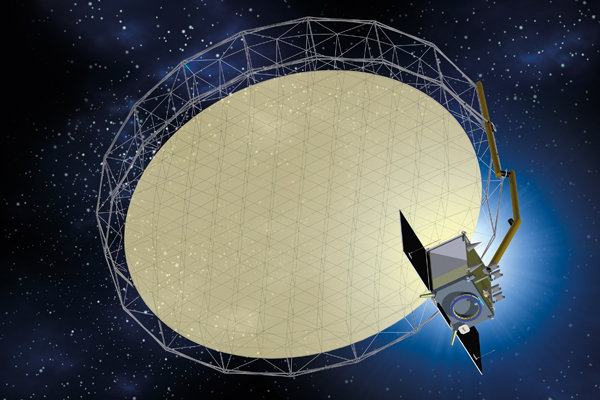

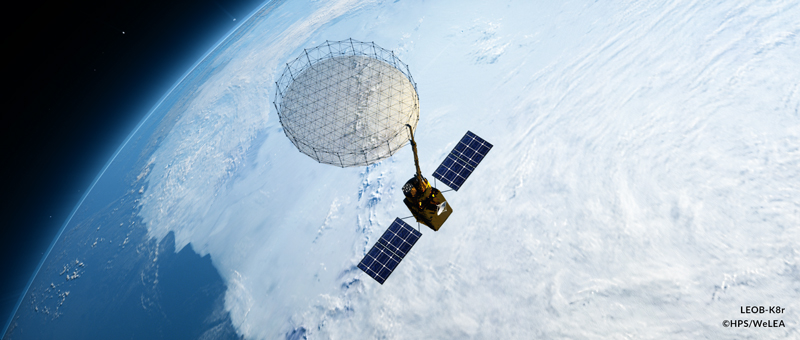

Large Deployable Reflector Subsystems

Increasing complexity and diversity of space-based applications for civil and defense purposes will continuously require very large antennas. At the same time the demand for lower costs of transportation inevitably leads to smaller satellites and/or to lower stowage volume inside the launcher fairing. Large deployable antennas will therefore become for some applications the strategic key to solve this dilemma.

On the level of subsystems in Europe the Bavarian company HPS has very early raised the claim for leadership in the field of Large Deployable Reflector Subsystems (LDRS) with focus on scalability, modularity, low storage space, low mass, high surface and pointing stability and – last, not least – price. The HPS-offer, in cooperation with mainly the Munich company LSS, covers each and every application in the field of earth observation, telecommunications, science and military. It comprises the fully subsystem with reflector, arm/boom, hinges, HDRM, thermal hardware, harness, deployment control electronics, EGSE and deployment MGSE.

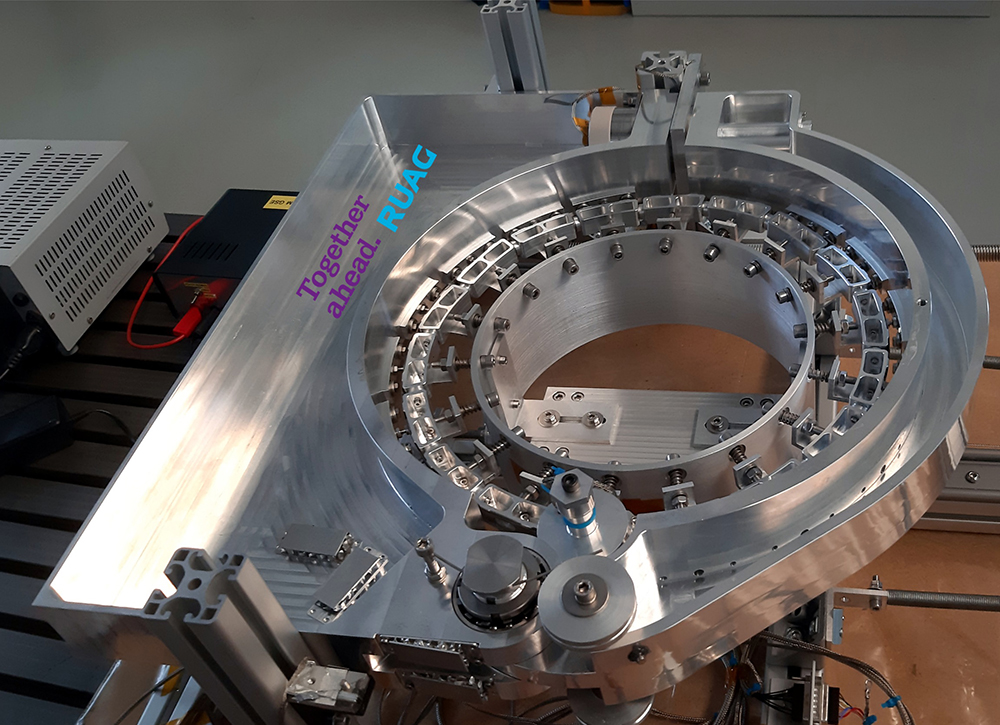

HPS Germany acts as LDRS-Prime and is responsible for the subsystem configuration, design & analysis, the reflector RF design, the reflective metallic mesh, the deployable arm, the LDRS integration and test. Yet another basis for its solid leadership is HPS´ tight cooperation with more than 15 highly experienced European companies (mostly SME), especially with the German companies LSS (deployable reflector assembly), Beyond Gravity Germany (formerly RUAG Space Germany) (HDRM/Hinge) and von Hoerner & Sulger (electronics, harness, EGSE).

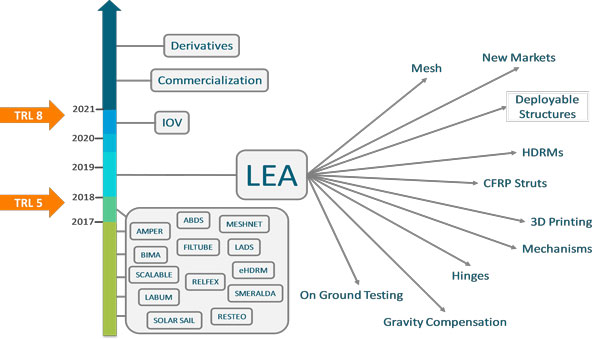

Meanwhile this strong consortium called “WeLEA” has reached with its product “LEA” a reliable and sustainable European source for LDRS:

- LEA-C5 (5m diameter, C-band): the reflector assembly has successfully been deployment tested in 2016.

- LEA-X5 (5m diameter, X-band applications): a complete PFM-subsystem is manufactured and tested within 2020.

- LEA-L12 (12m diameter, L-band): the complete subsystem has been designed in 2019.

- LEA-K8r (8m diameter, L- to Ka-band, rotating): the complete subsystem has been designed in 2019. The reflector-assembly EM including upper arm segment will complete its tests within Q1/2021.

- LEA-C7+ (7-10m diameter, C-band): the full subsystem is under investigation within a Phase 0.

Contact:

For further information please contact our chief engineer.

Or directly: LDRS@hps-gmbh.com

References:

→ Success Trajectory

HYDROTERRA-LDRS Phase 0

- Phase 0 under ESA’s Earth Explorer Program (EE-10)

- Objectives:

- Risk Retirement Activities for System Study

- Concept for the LDRS

- Accommodation assessments on satellite platforms

- Performance and budget predictions

- Development Planning.

- Customer: Airbus (UK/DE).

- LDRS-Prime: HPS-Germany with LSS as subcontractor

- Timeframe: 02/2020 – 09/2020.

CIMR LDRS Phase B2/C/D/FM2 (EQM, PFM, FM2)

Description

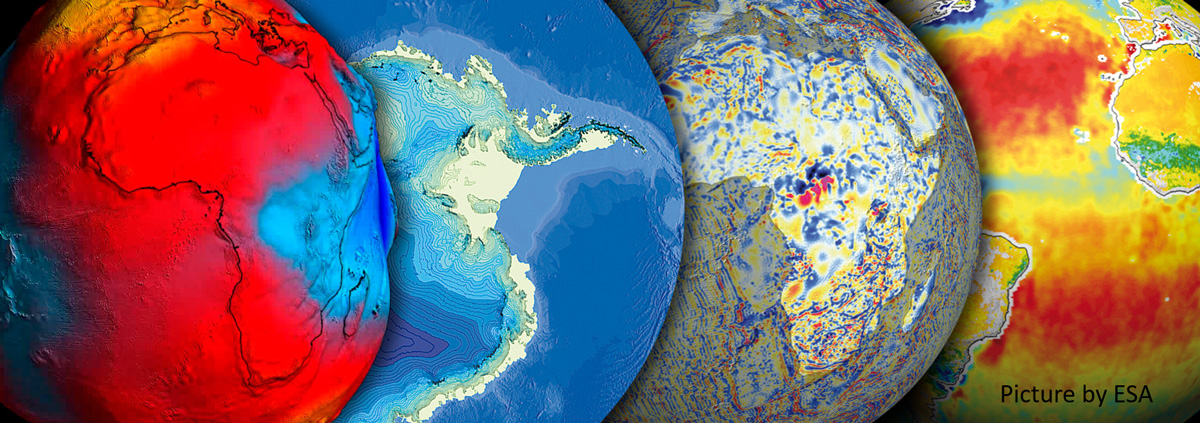

- CIMR-mission provides significant contribution to „Integrated European Policy for the Arctic“:

- Improved continuity (sub-daily) in monitoring of floating sea ice (spatial and temporal resolution)

- Global coverage of sea surface temperature measurements

- Specific focus on the Polar Regions

- Two satellites (PFM + FM2) are contracted to ThalesAleniaSpace Italy under ESA/EC’s Copernicus Program

- HPS GmbH, Munich, Germany, has been contracted by the satellite prime for the development, manufacturing and testing of the Large Deployable Reflector Subsystem (LDRS)

- LSS GmbH, Munich, Germany, is main partner and is contracted by HPS for the Deployable Reflector Assembly (DRA)

- In total, more than 15 companies (mainly SME) out of 7 European countries are part of the HPS-team, called “WeLEA”.

- 12/2020: Contract signature

- 2022: PDR

- 2027: Launch of PFM satellite.

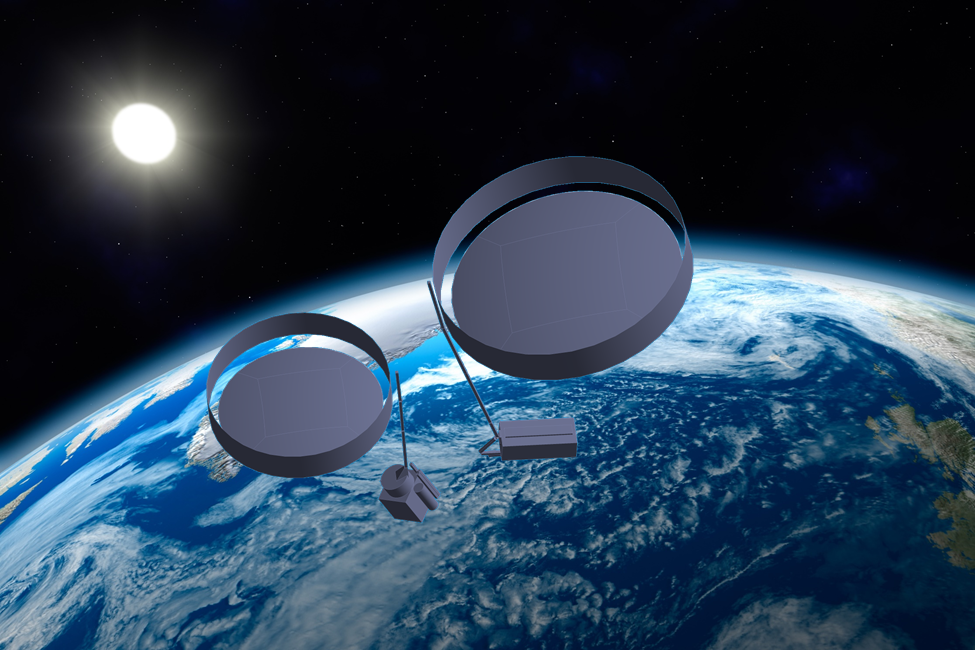

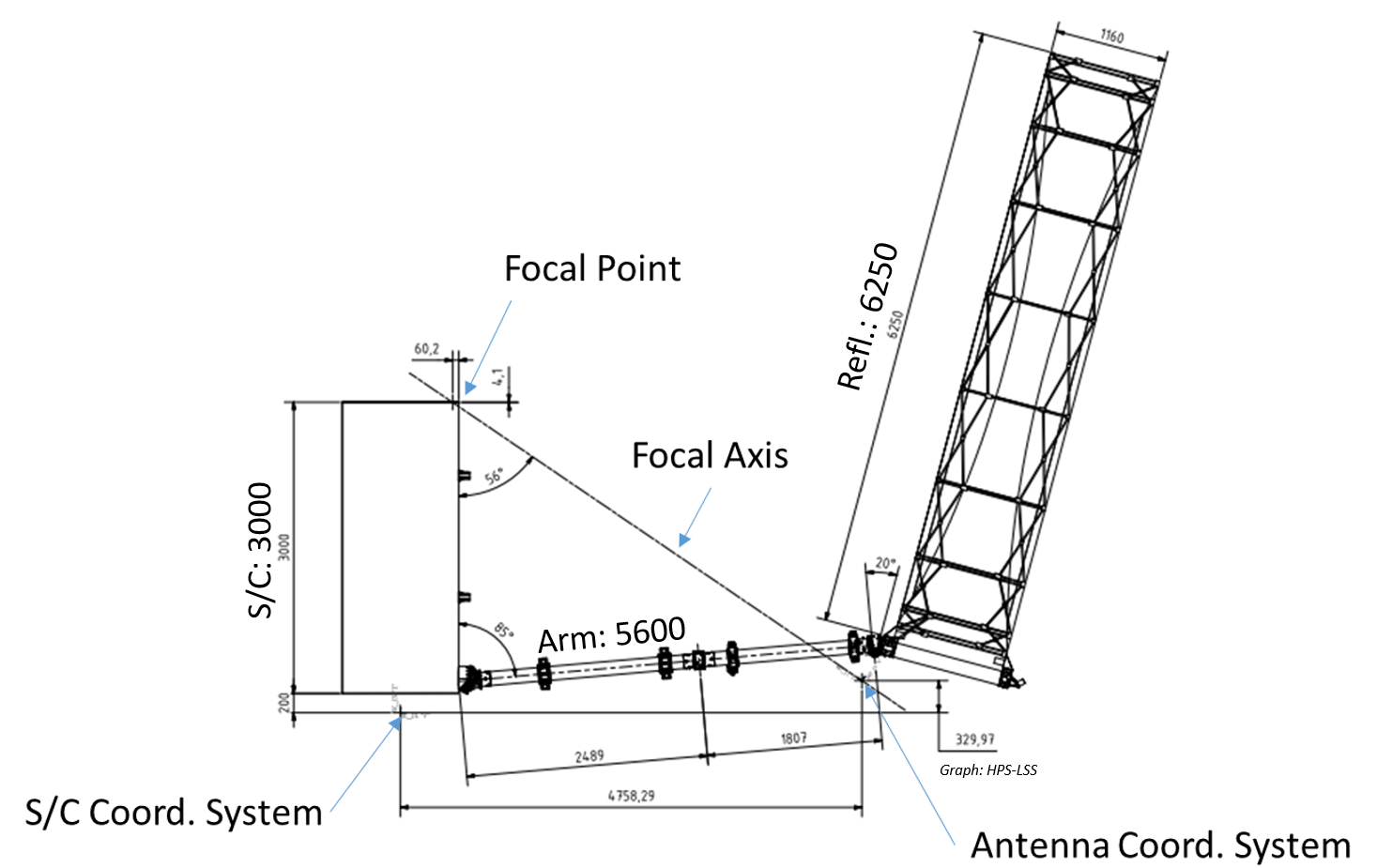

CIMR-LDRS Features:

- 8 m reflector diameter

- 8 m arm length

- L- up to Ka-Band application

- Rotating Subsystem, comprising:

- Deployable reflector assembly

- Deployable arm assembly

- HDRM

- Electronics

- Harness

- Thermal Hardware

- MGSE & EGSE

Phase B2 Objectives:

- Definition of interfaces to satellite

- Detailed design of the LDRS-EQM

- Intensive breadboard test program

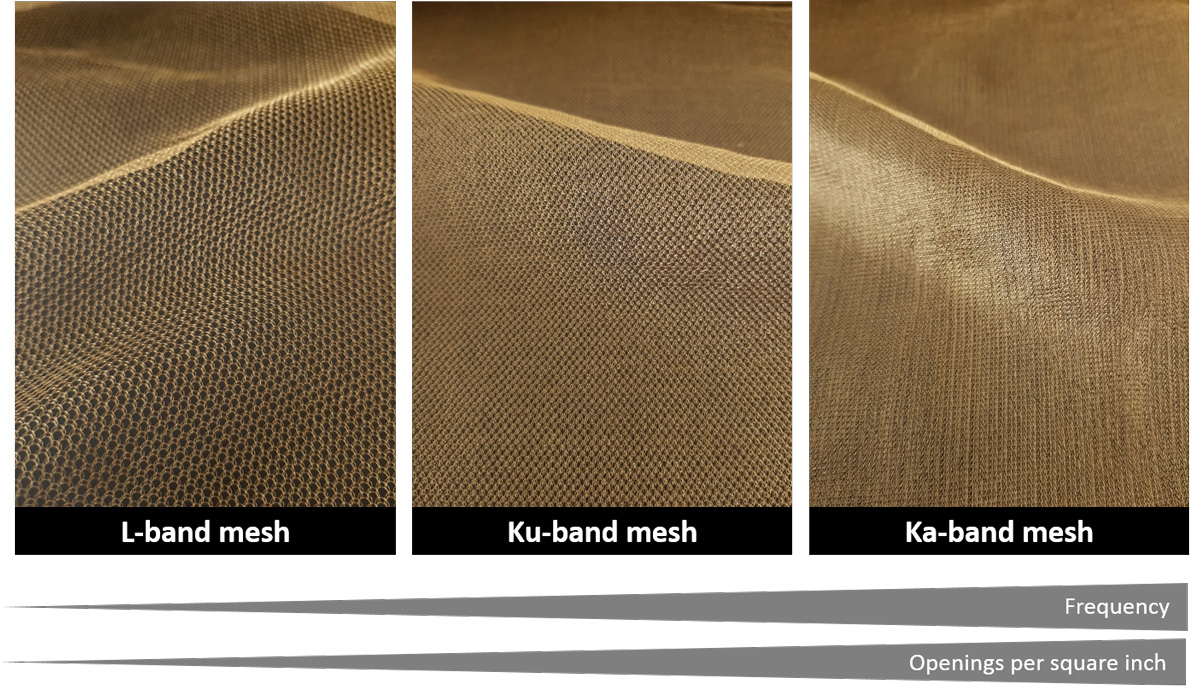

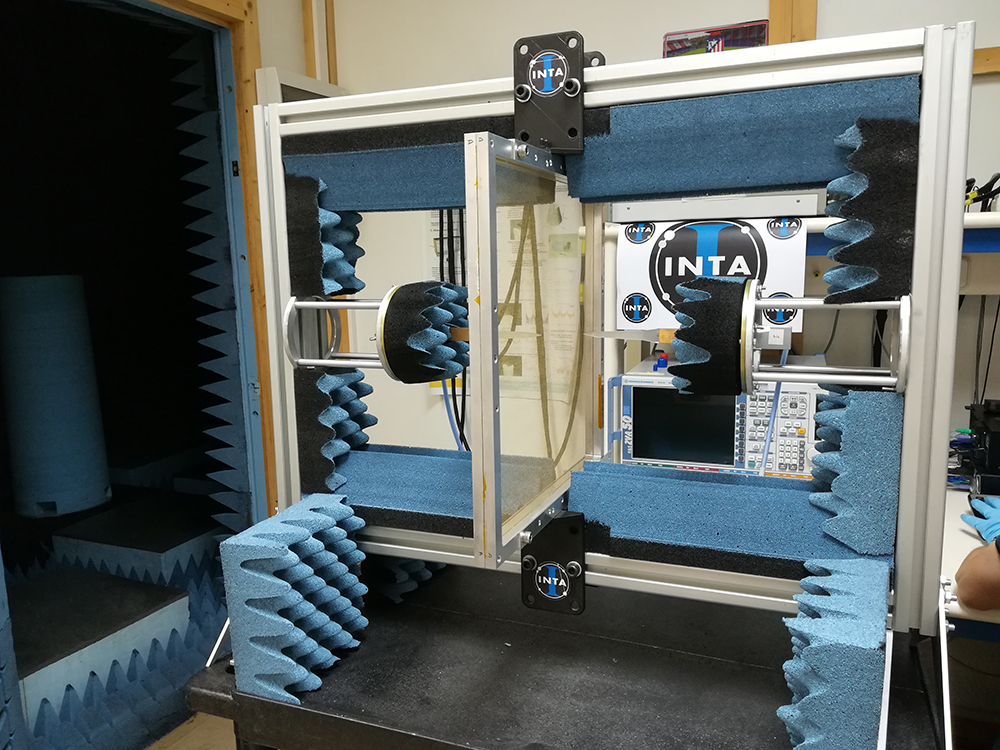

- Development and production of Ka-band mesh by the HPS/IPROTEX joint-venture “HPtex” (with cooperation from Frauenhofer ISC)

- Demonstration of Technology Readiness Level 5 within 6 months and TRL 6 at PDR.

CIMR-/ROSE-L-LDRS Phase A/B1

- Phase A/B1 under ESA/EC’s Copernicus Program

- Objectives:

- Design concept for the LDRS

- Accommodation assessments on satellite platforms

- Performance and budget predictions

- Development Planning

- Ka-band mesh pre-development.

- Customers:

- Airbus (UK/ES/DE) for CIMR & ROSE-L & Mesh Pre-development

- ThalesAleniaSpace/OHB (IT) for CIMR & Mesh Thermal Samples.

- LDRS-Prime: HPS-Germany

- Subcontractors: LSS and further WeLEA-partners

- Timeframe: 05/2018 – 09/2020

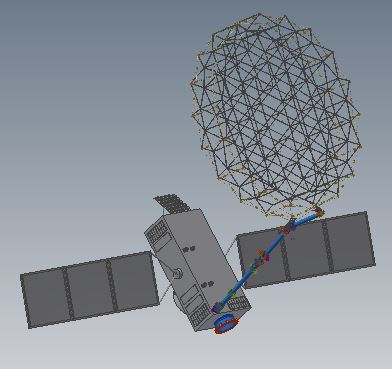

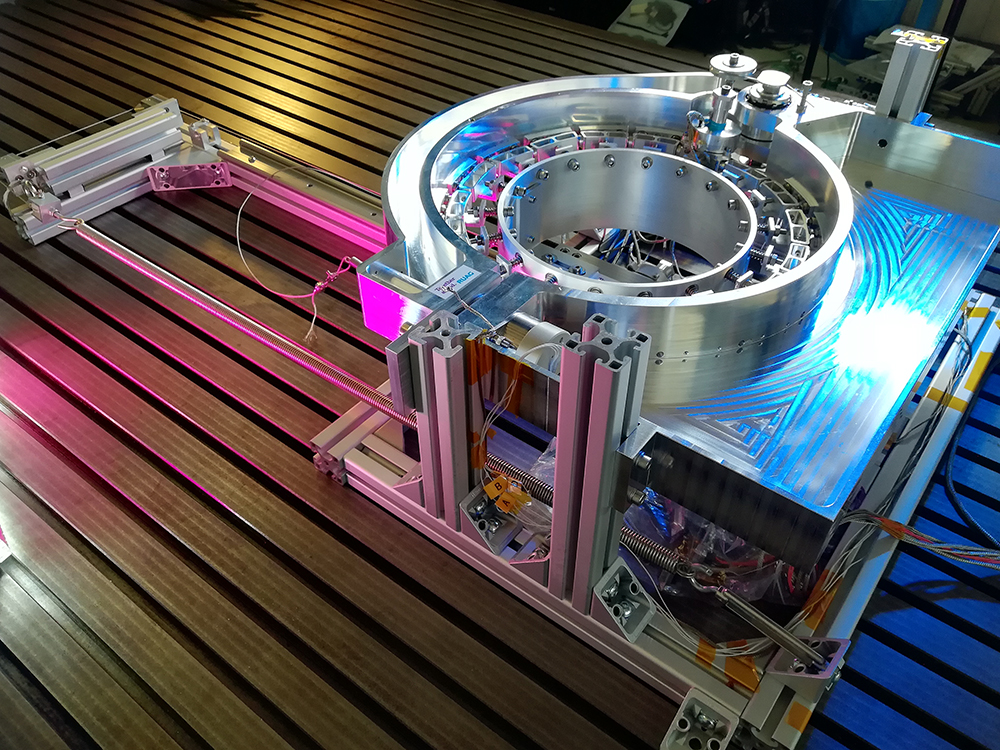

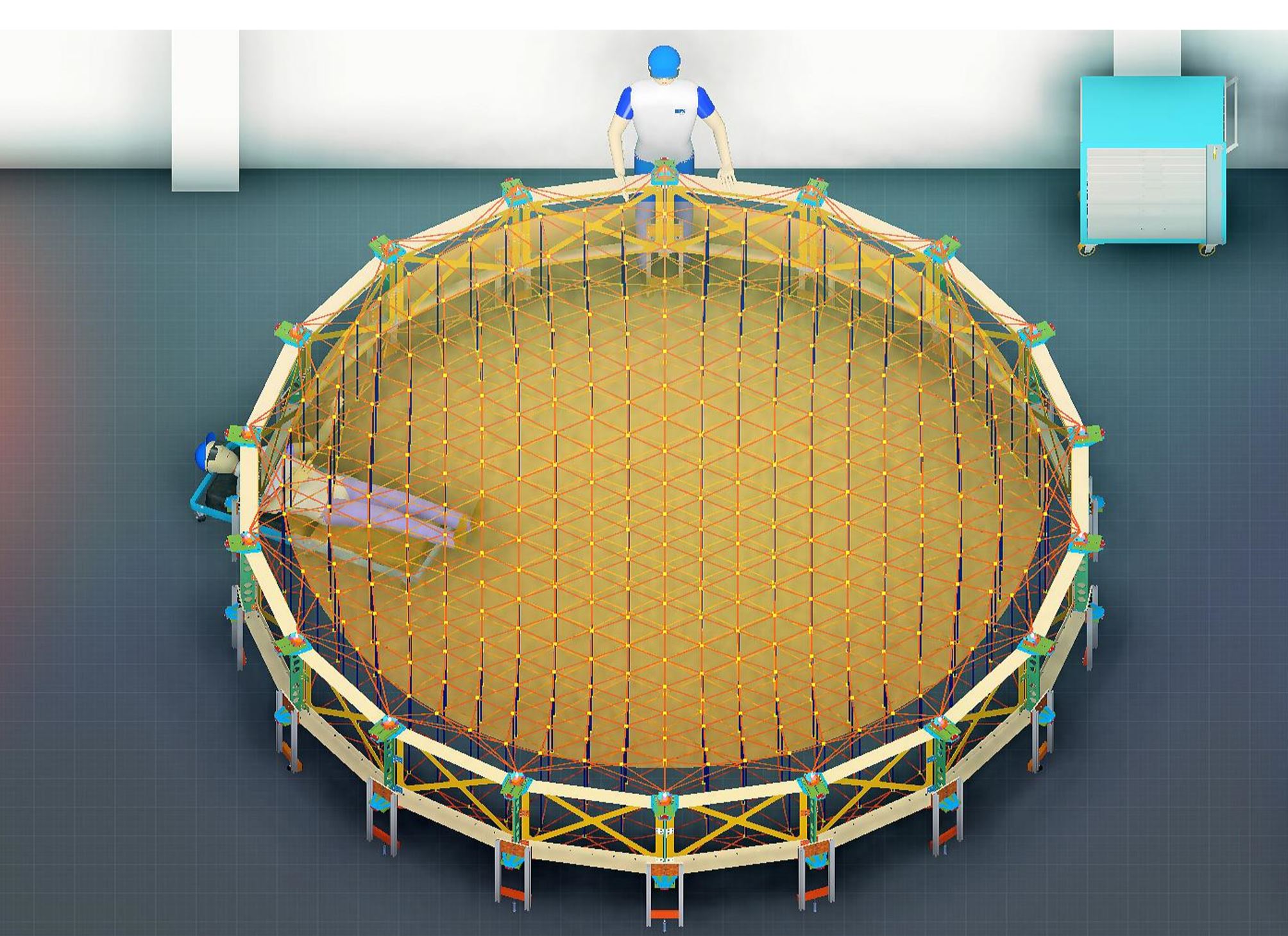

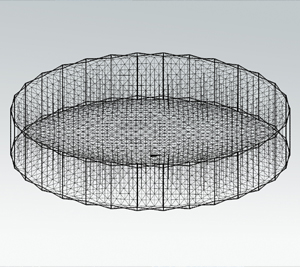

Deployable Reflector for EO (LEOB)

Description:

- Development project under ESA’s Earth Observation Program / Copernicus

- Applications:

- Copernicus Mission CIMR (fresh data every day on the pattern of sea ice variability in the polar regions)

- Copernicus Mission ROSE-L (tracking of biomass changes and mapping of life and woodland, distribution of vegetation and soil humidity)

- Objectives:

- Design and analysis of Large Deployable Reflector Subsystems (LDRS) for CIMR and ROSE-L

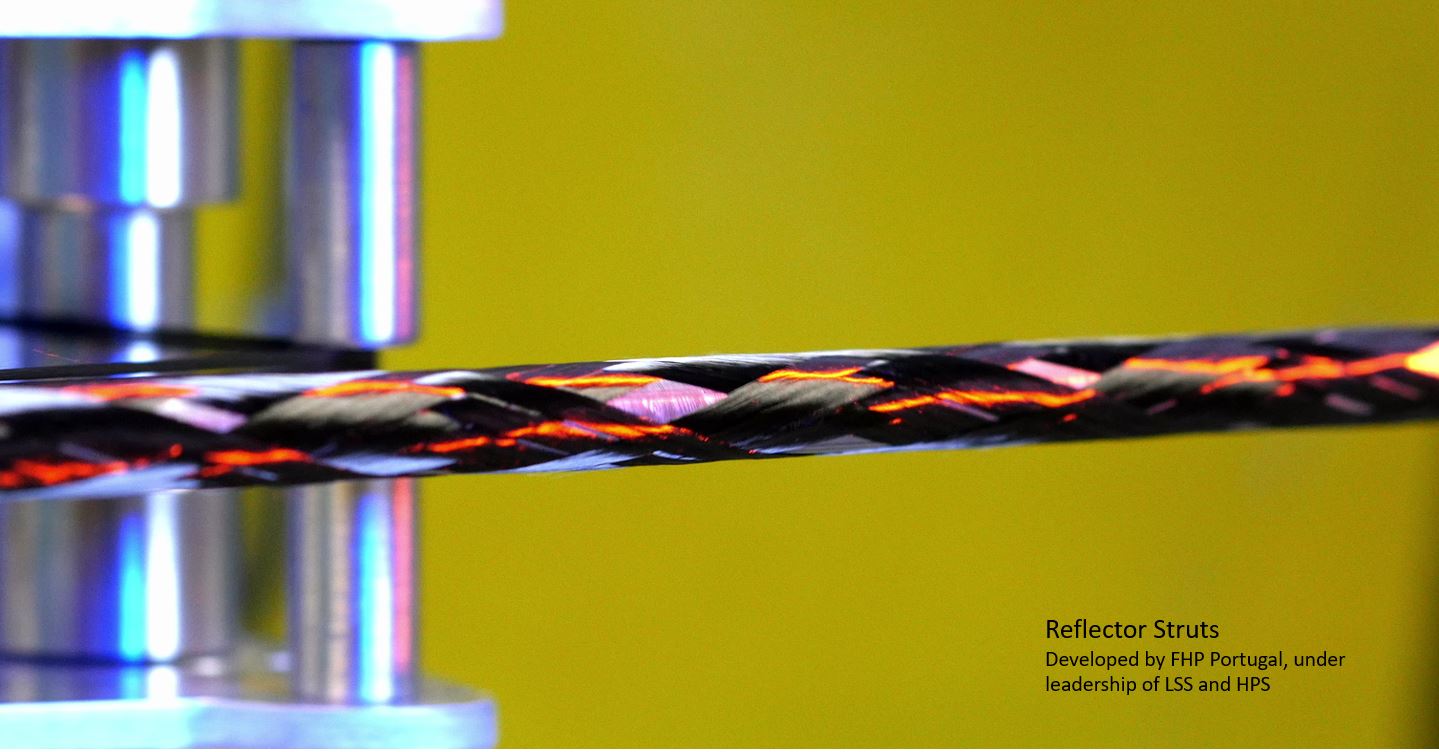

- Critical breadboarding (reflector struts, bay segments, L- and Ka-band mesh)

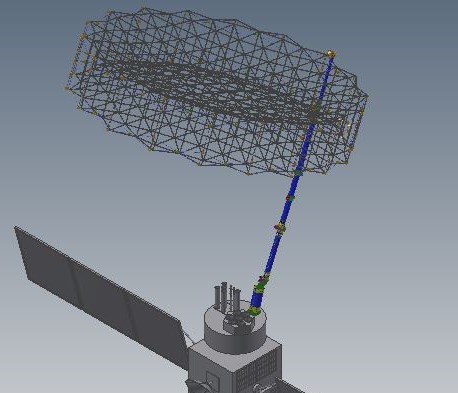

- Realization of an Engineering Model (“LEA-K8r EM”) for CIMR application

- EM includes deployable reflector assembly plus upper arm segment, HDRM, electronics, GSE

- Large test campaign (deployment, surface accuracy, thermal, vibration, RF)

- Longterm development planning

- Budget: 5 Mio Euro in contract to ESA

- Timeframe: 4/2019 – 04/2021

- Start TRL: 5, End TRL: 6

References:

Youtube-LEA-Movie

Team (“WeLEA”):

- 17 development partners (DE, RO, PT, ES, DK, SE, FR)

- Lead: HPS-Germany (project & technical management)

- Main subcontractor: LSS (deployable reflector assembly)

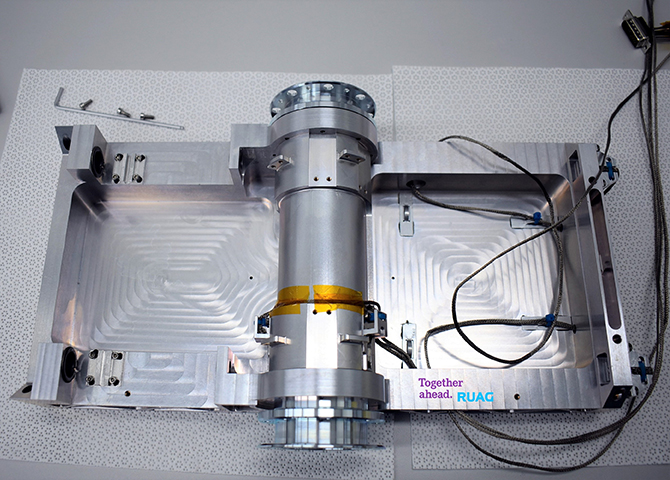

- Further subcontractors: RUAG, TICRA, FHP, vH&S, INVENT, HPTEX, LUMA, ARQUIMEA, ETAMAX, INEGI, HPS-RO, INTA, AIRBUS, DLR, ONERA, WSS.

Features:

- LEA-K8r EM (LEOB-EM) includes: reflector, deployment mechanisms, metal mesh, upper arm segment, upper hinge, reflector hold-down-and-release-mechanisms, thermal hardware, harness, deployment control electronics, deployment test-MGSE & -EGSE, RF test-GSE.

- LEA-K8r specification:

- 7.4 m reflective aperture diameter

- 9.1 m ring diameter (max.)

- 8.3 m arm length

- F/D = 0.9

- Rotation speed: 8 rpm

- L-band (1.3 GHz) to Ka-band (37 GHz)

- Subsystem total onboard mass: 167 kg

- Deployed total mass: 114 kg.

- LEA-L12 specification:

- 12 m reflective aperture diameter

- 14.6m ring diameter (max.)

- 12.8m arm length

- F/D =0.875

- L-band(1.215-1.3 GHz)

- Subsystem total onboard mass: 235kg

- LEA-products in general are scalable:

- 3 m to 25 m reflector diameter

- 1 m to 20 m arm lenght

- RF frequencies: C-, L-, S-, P-, Ku-, Ka-Band.

Highlights:

- 15.04.2019: Kick-off

- 10.07.2019: Breadboard TRR & selection of CIMR reflector configuration for EM

- 12.12.2019: Detailed Design Review

- Sept. 2020 (tbc): Test Readiness Review

- Dec. 2020 (tbc): Completion of 1st deployment& accuracy test

- April 2021 (tbc): Delivery and Contract Close-out.

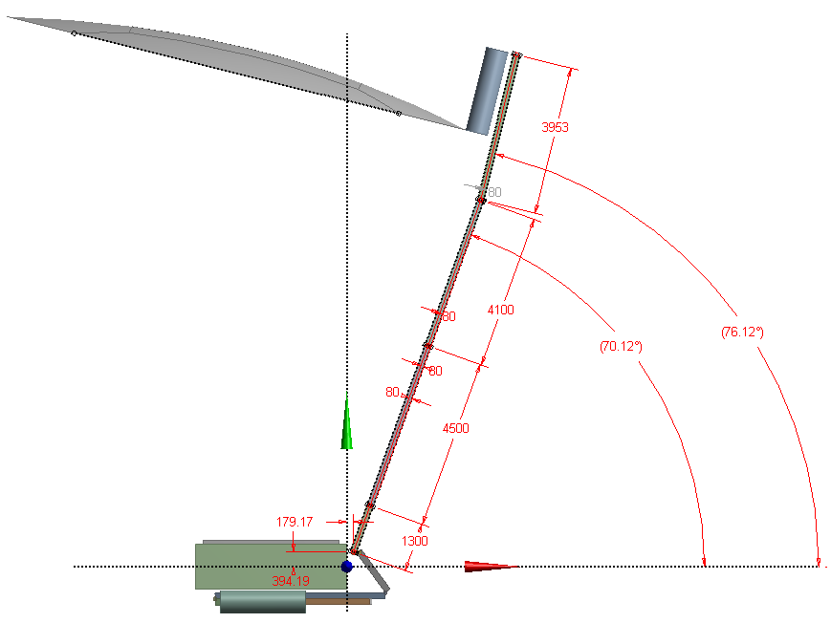

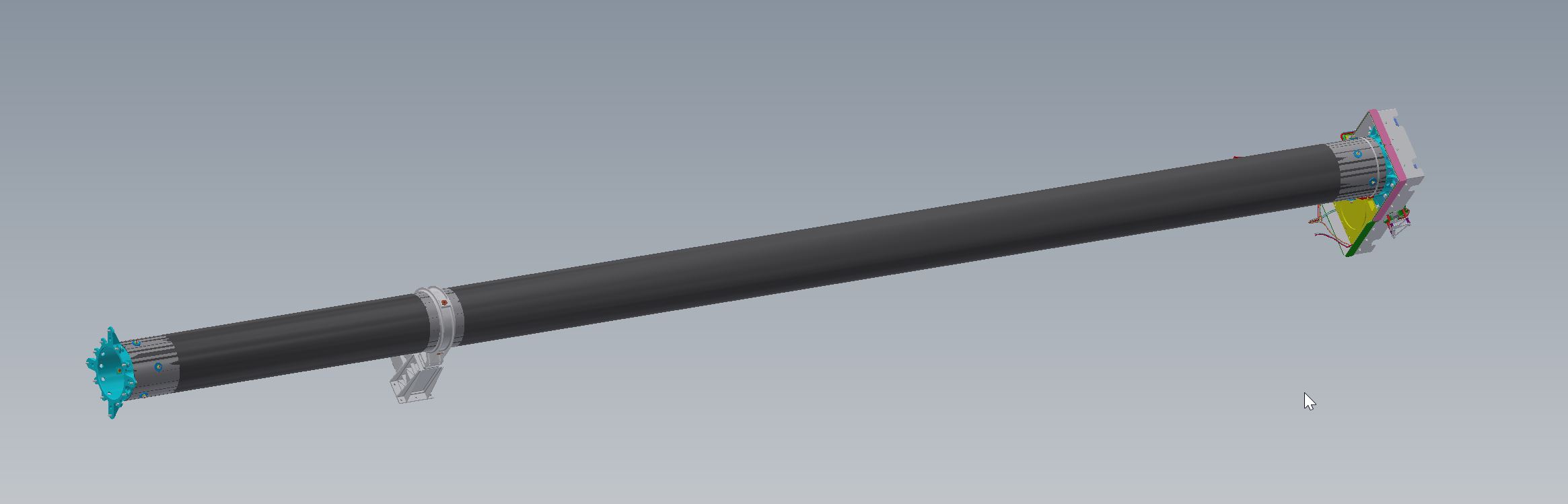

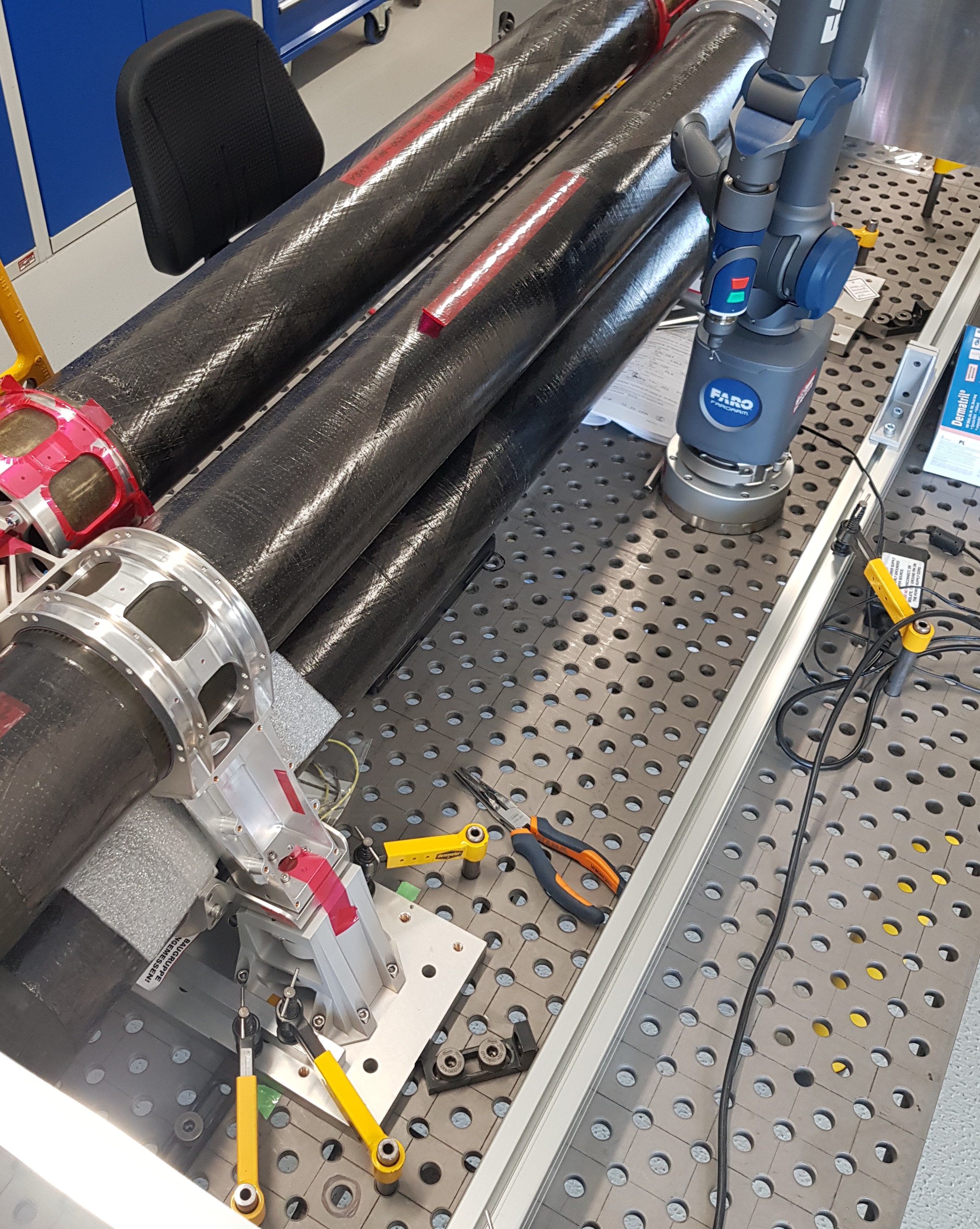

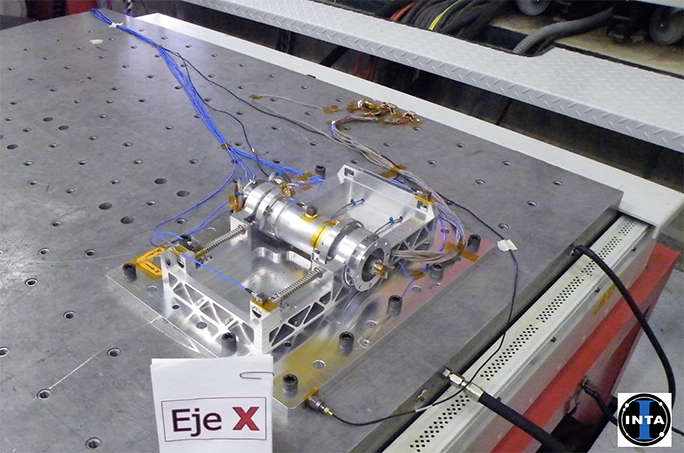

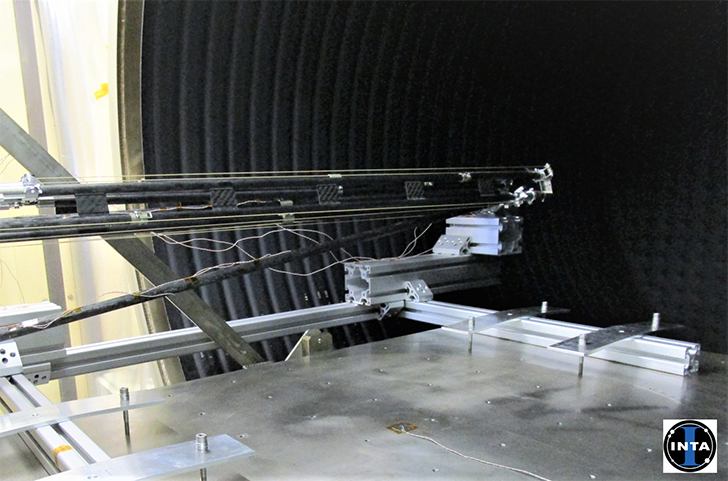

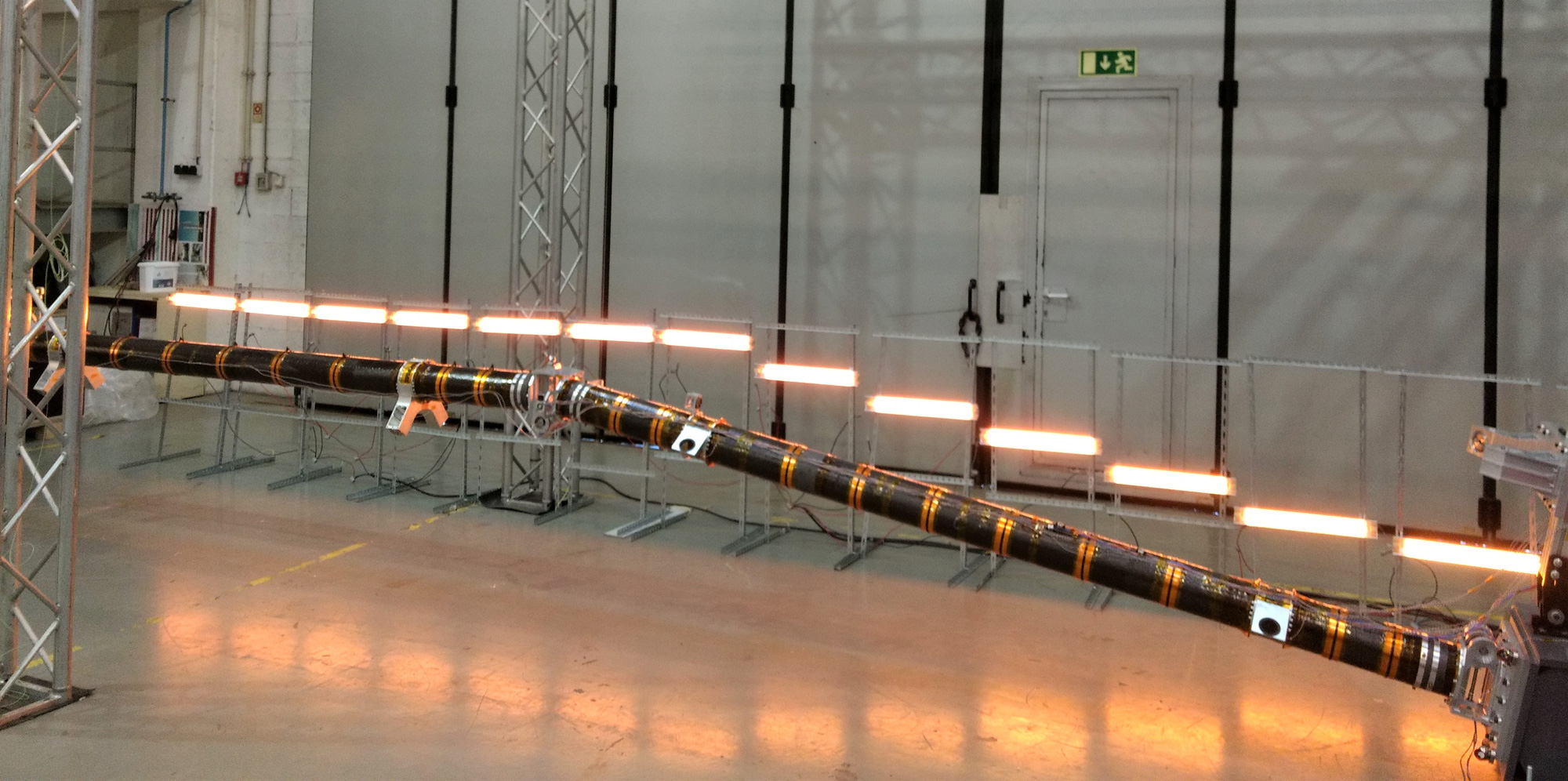

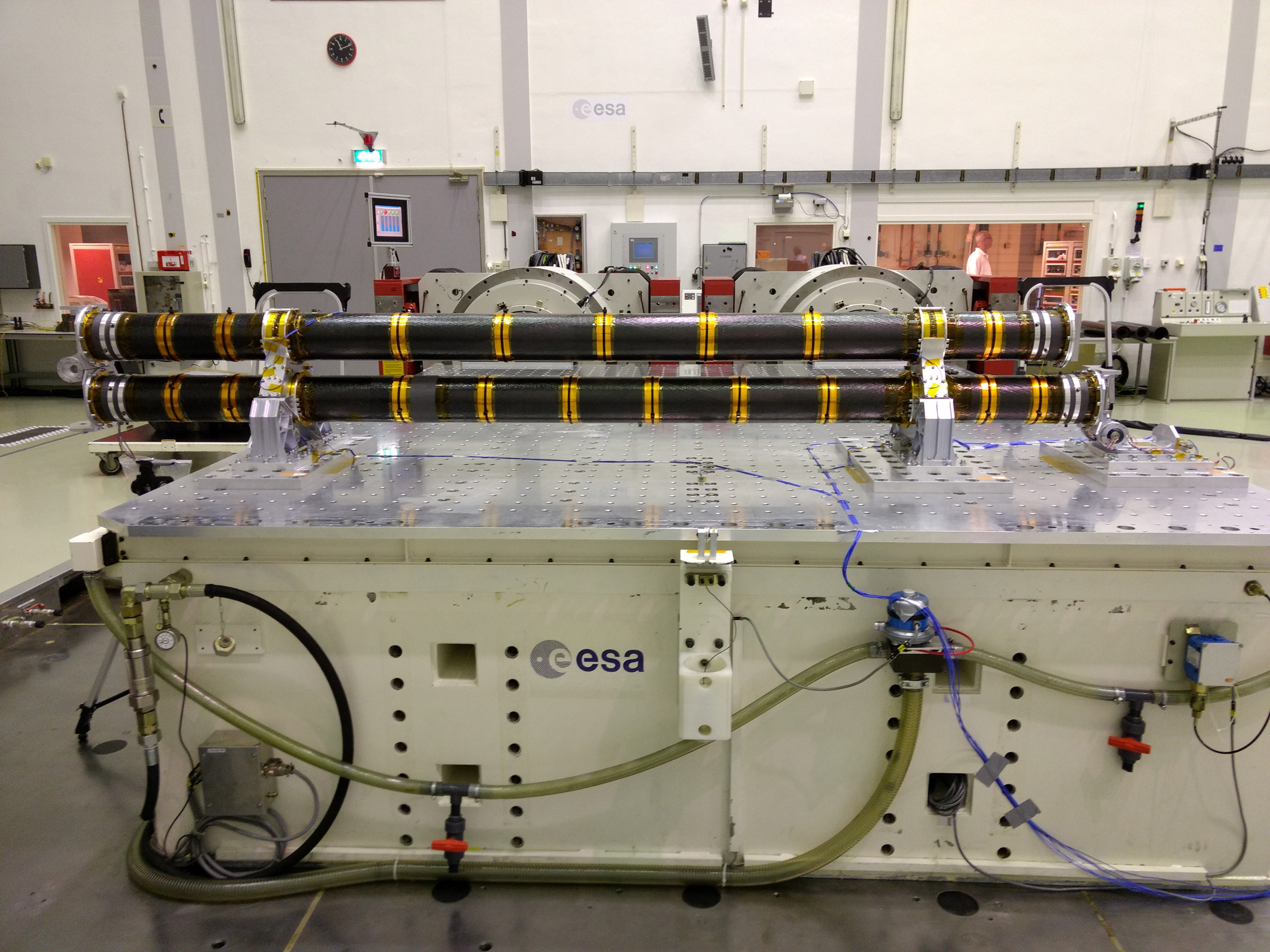

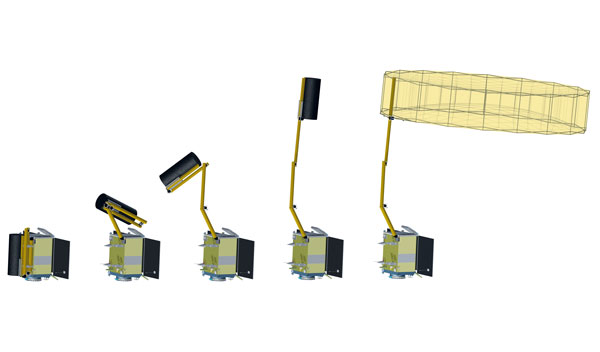

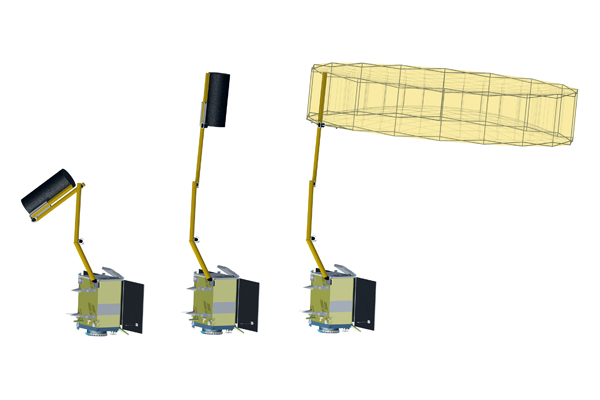

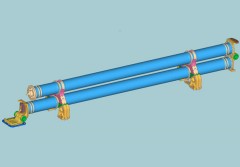

Deployable Arm for EO (LADEA)

Description:

- Development project under ESA’s Earth Observation Program

- Objectives:

- Realization of an Engineering Model of a deployable arm assembly

- 8m length for CIMR application (rotation of the LDRS on top of satellite, Ka-band)

- Large test campaign (deployment, surface accuracy, thermal, vibration)

- Budget: 0.5 Mio Euro in contract to ESA

- Timeframe: 1/2020 – 01/2021

- Start TRL: 5, End TRL: 6

Team (“WeLEA”):

- 9 development partners (DE, RO, ES, PT)

- Lead: HPS-Germany (project & technical management)

- Subcontractors: INVENT, RUAG, FHP, vH&S, LSS, INEGI, HPS-RO, INTA.

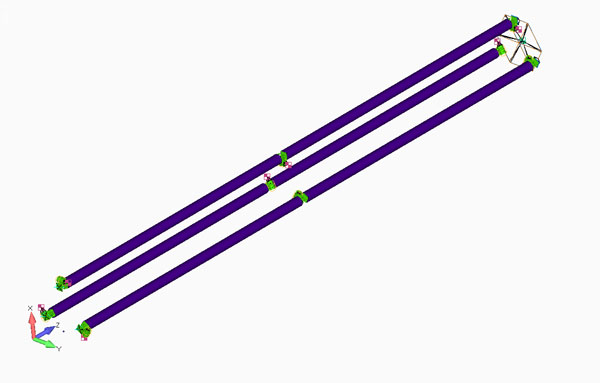

Features:

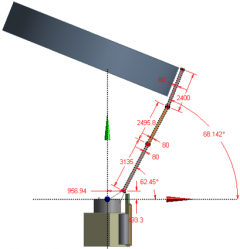

- LEA-K8r Arm EM (LADEA-EM) includes: two arm segments, arm hinges, MLI deployment control electronics EGSE, deployment test-GSE.

- LEA-K8r Arm specification (in full configuration):

- 3 arm segments, 2 hinges

- 9.7 m arm length

- Rotation speed: 8 rpm

- Arm tip accuracy (with mounted reflector and under rotation): < 1.4 mm

- Arm tip thermo-elastic stability: +/- 0.5 mm

- Deployed total mass: 51 kg (including subsystem harness).

Highlights:

- 20.01.2020: Kick-off

- 26.03.2020: Preliminary Design Review

- June 2020 (tbc): Manufacturing Readiness Review

- Aug. 2020 (tbc): Test Readiness Review

- Oct. 2020 (tbc): Test Review Board

- Jan. 2021 (tbc): Delivery and Contract Close-out

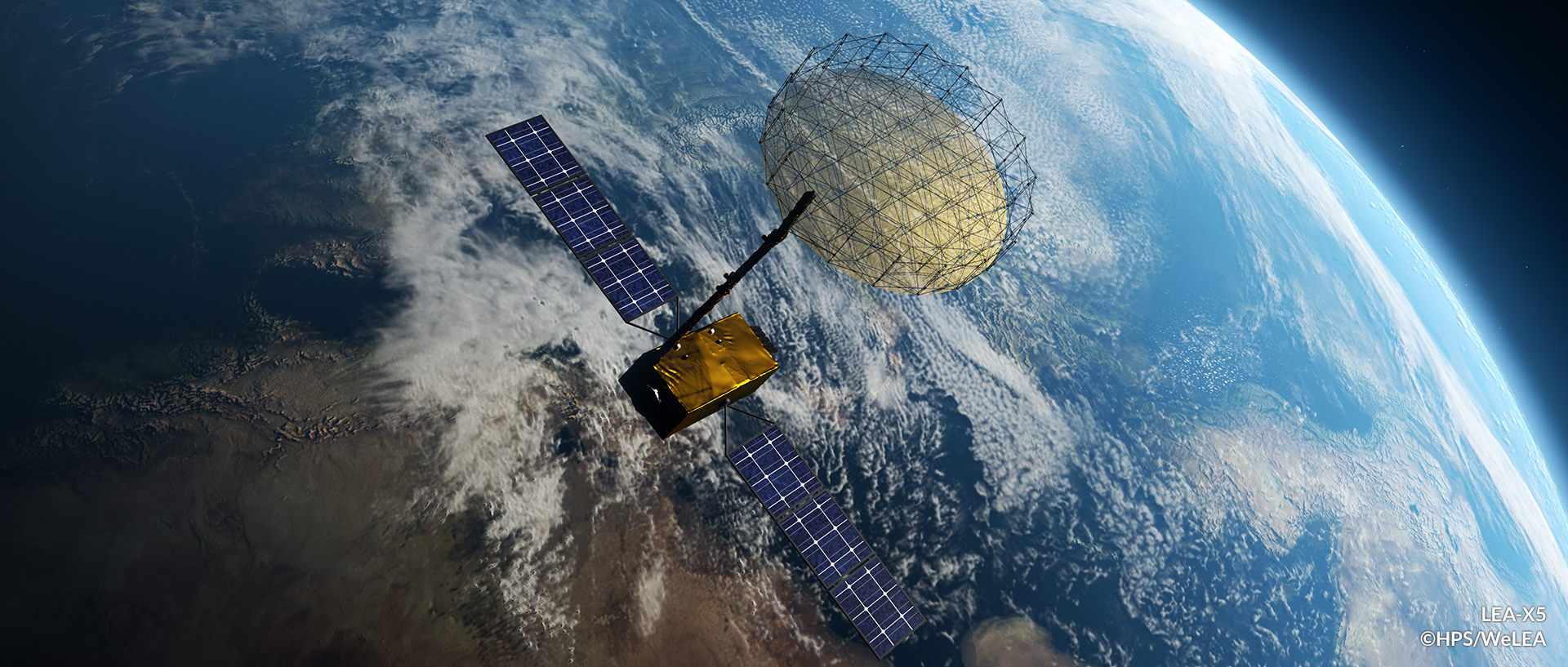

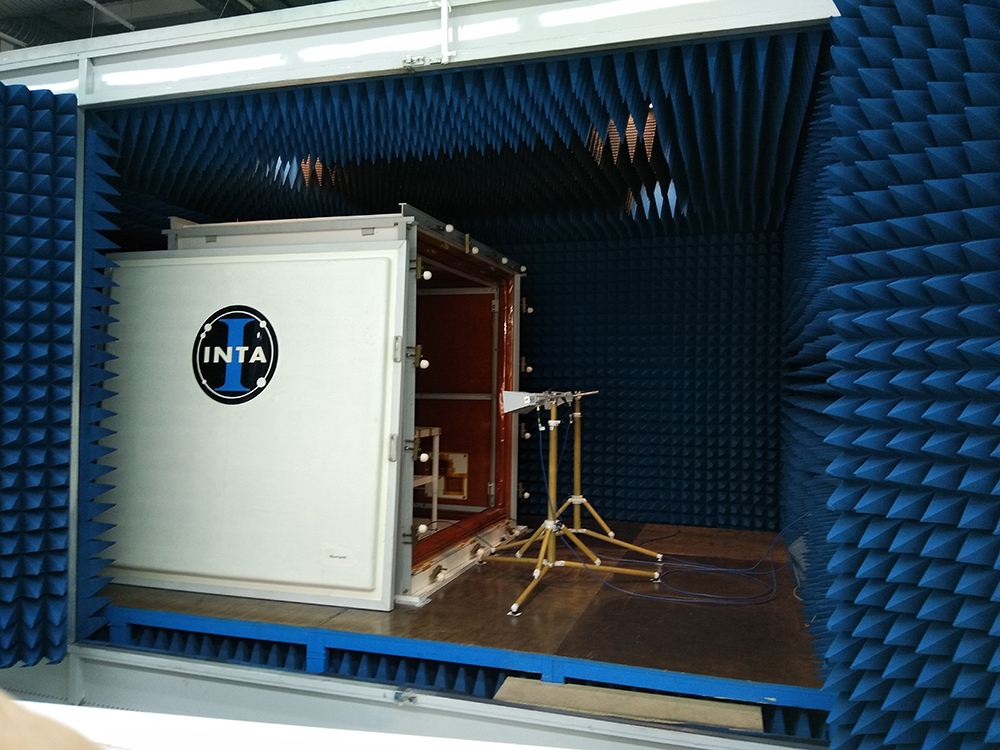

Large European Antenna (H2020 LEA)

Description:

- Development project under the European H2020 Program (sector „non-dependence“)

- Space application: Earth Observation, Telecom, Military

- Objective:

- Realization of a Protoflight-Model (“LEA-X5 PFM”)

- Complete Large Deployable Reflector Subsystem

- 5m aperture diameter for X-band applications

- Large test campaign (deployment, surface accuracy, thermal, vibration, RF)

- PFM is offered for free to potential satellite programs in exchange to flight opportunity

- Budget: 5 Mio Euro grant by European Commission + 2 Mio Euro team’s investment

- Timeframe: 11/2017 – 02/2021

- Start TRL: 5, End TRL: 8

- Ready to launch: Q2/2021

References:

Team (“WeLEA”):

- 16 development partners (DE, PT, ES, DK, SE)

- Lead: HPS-Germany (implementation & technical management)

- Main contribution: LSS (deployable reflector assembly)

- Further consortium partners: FHP, RUAG, TICRA, vH&S, INVENT, HPTEX, LUMA, ETAMAX, INEGI, INTA, AIRBUS, OHB, TAS, WSS.

Features:

- LEA-X5 PFM includes: reflector, deployment mechanisms, metal mesh, arm, hinges, hold-down-and-release-mechanisms, thermal hardware, harness, deployment control electronics, deployment test-MGSE & -EGSE, RF test-GSE.

- LEA-X5 PFM specification:

- 5.1 m reflective aperture diameter

- 6.15 m ring diameter (max.)

- 5.65 m arm length

- F/D = 1.0

- X-band (10.65 GHz) for structure and in-orbit performance

- Ku-band (18.7 GHz) for RF-compatibility tests

- Subsystem total onboard mass: 110.3 kg

- Deployed total mass: 98 kg.

- LEA-products are scalable:

- 3 m to 25 m reflector diameter

- 1 m to 20 m arm lenght

- RF frequencies: C-, L-, S-, P-, Ku-, Ka-Band.

Highlights:

- 02.11.2017: Kick-off

- 18.01.2018: Major LEA-X5 PFM parameters specified.

- 20.07.2018: Preliminary Design Review

- 11.04.2019: Critical Design Review

- Sept. 2020 (tbc): Test Readiness Review

- Oct. 2020 (tbc): Completion of RF test

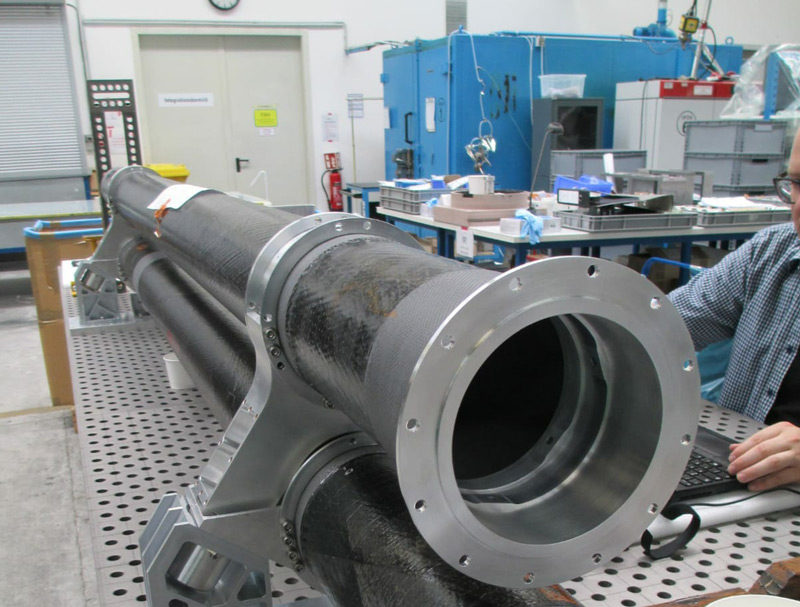

Deployable Arm Concept (ABDS)

Description:

- Development project under ESA’s Technology Research Program

- Subject: Deployable arm assembly (DAA) for large deployable reflector subsystems (LDRS), comprising of

- Ultra-stable deployable CFRP boom segments

- Highly reliable deployment hinges

- Fixed at hold-down-and-release mechanisms.

Remark: Derivates feasible for heavy scientific instruments to be deployed.

- Objectives:

- Development of a two-segment 6m deployable arm Engineering Model (EM)

- Test campaign (functional deployment, thermo-elastic distortion, vibration, deployment under thermal vacuum)

- Team:

- Prime Contractor to ESA: HPS Germany

- Subcontractors: RUAG (DE), INVENT (DE), DLR (DE), INEGI (PT), VTT (FI), OHB (DE)

- Budget: 1.1 Mio Euro

- Timeframe: 07/2016 – 12/2018

- End-TRL: 5-6 (depending on application)

Special thanks to

- Julian Santiago Prowald and Alexander Ihle (Technical Officers at ESA), who are for us one of the initiators of the “European Solution of LDRS” and who contributed significantly to the technical progress.

Features:

- Modular and scalable extending up to 30 m length

- Pointing accuracy: 0,1 mm per m

- Stowed Eigenfrequency: > 130 Hz

- Deployed Eigenfrequency: > 1 Hz

- Mass: 8 kg/m

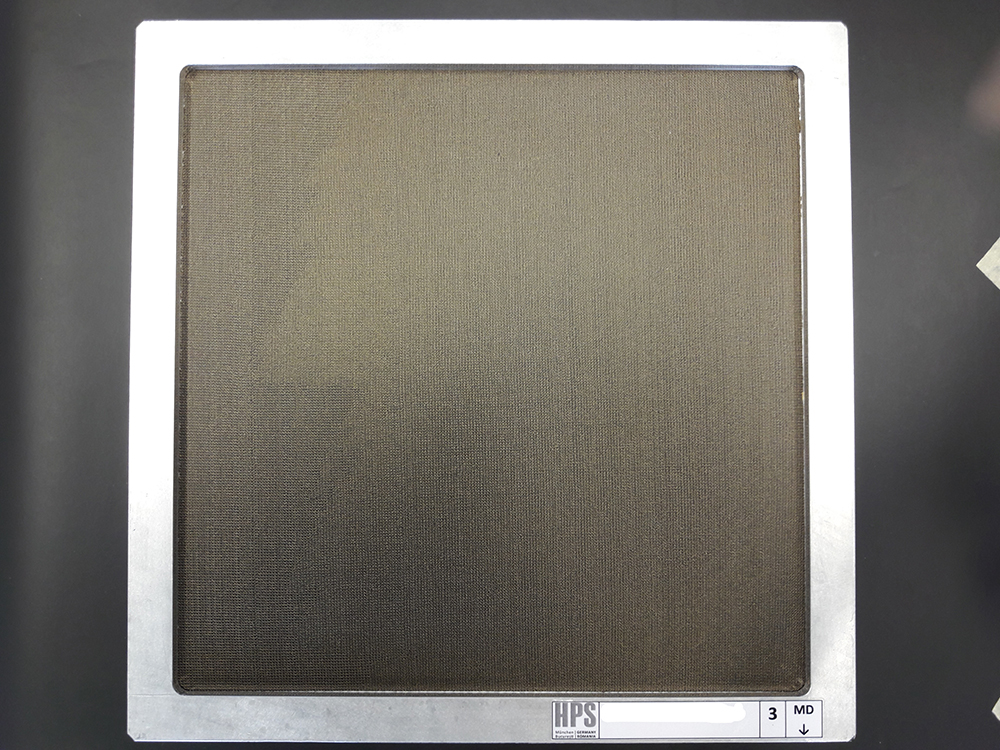

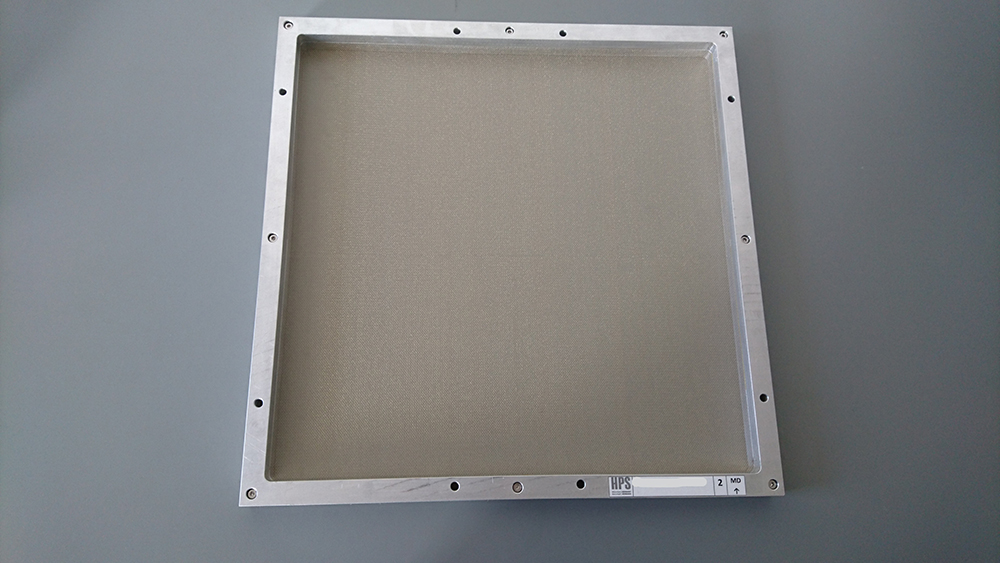

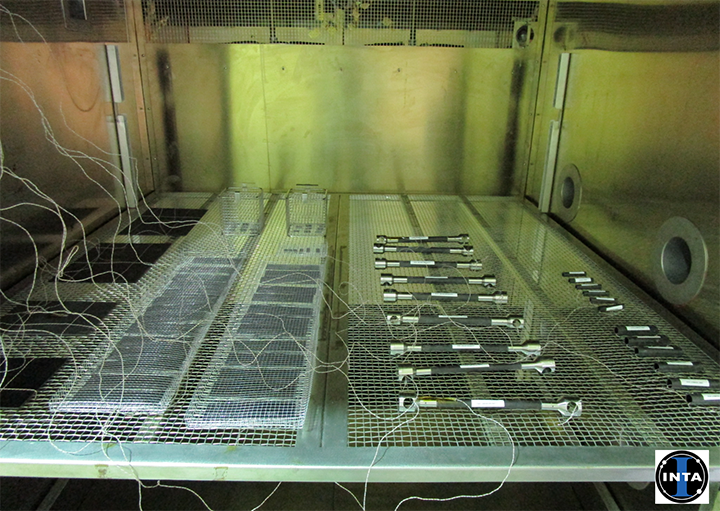

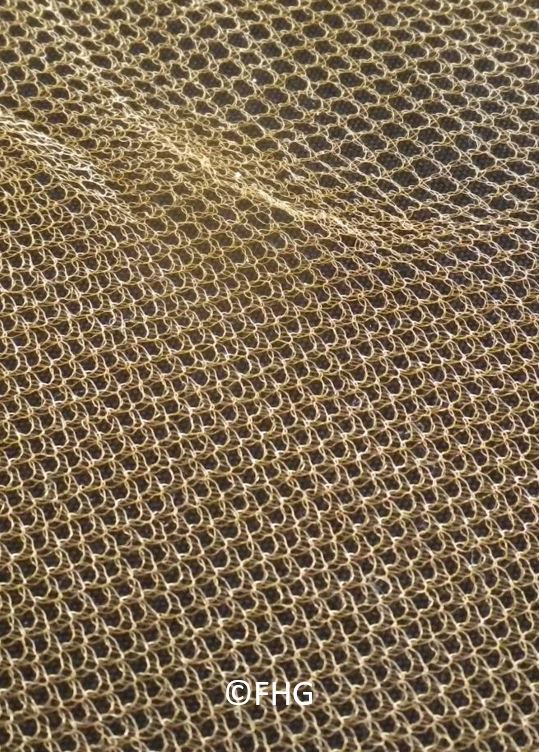

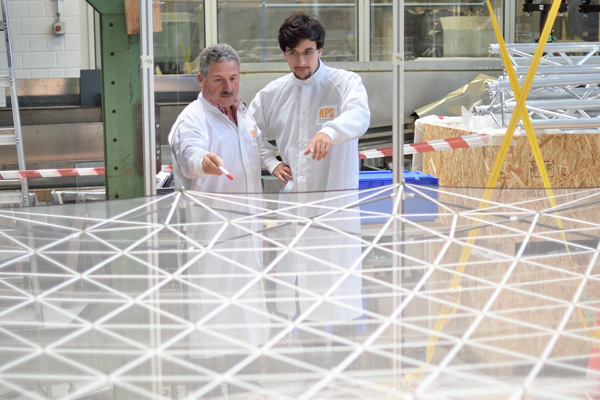

Reflective Metal Mesh (MESNET)

Description:

- Development Project ESA`s ARTES Program

- Objectives:

- Development of a Ku-band metal mesh for LDRS for telecom-applications

- Development of an highly accurate carrying network

- Extensive trade-off and selection of raw materials and processes

- Performance of extensive characterization tests

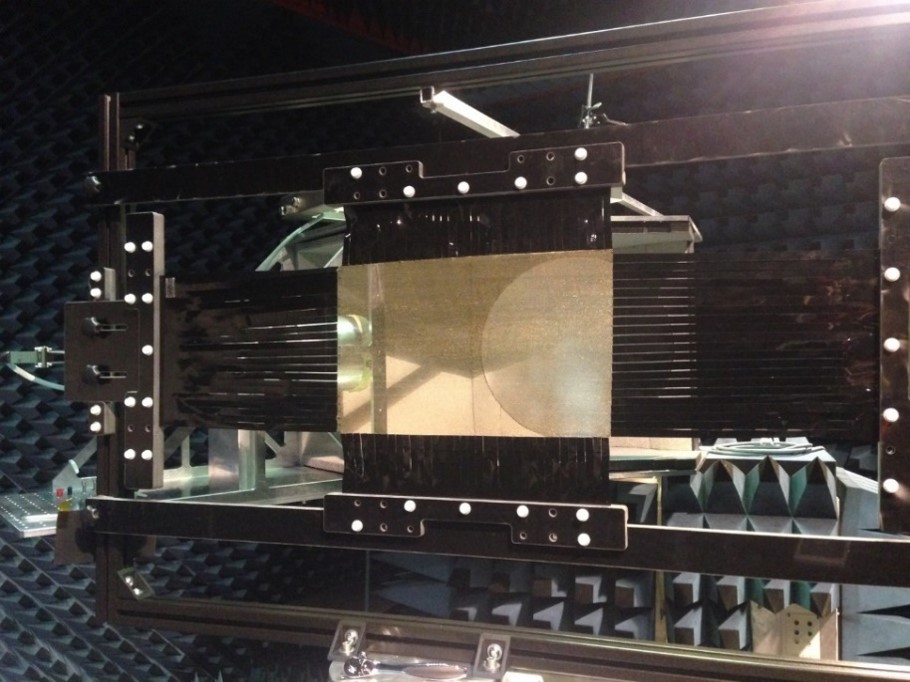

- Realisation of a 5m Engineering Model of a reflective surface

- Traceable step-by-step procedures for final assembly of mesh, network, and integration onto a reflector ring.

- Surface accuracy and thermo-elastic distortion test campaign

- Team:

- HPS Germany (prime contractor and mesh development)

- HPS Romania (subcontractor for carrying network manufacturing process development and EM assembly),

- Budget: 600 kEuro in contract to ESA plus 400 kEuro investment by HPS-DE, HPS-RO and further development partners.

- Timeframe: 04/2016 – 12/2020

- End TRL: 5-6

Special thanks to

- Jean Christophe Angevain (Technical Officer at ESA), who is for us one of the most important promoters of the “European Solution of LDRS” and who contributes significantly to all our mesh developments.

Features for Engineering Model:

- 5 m ring diameter

- C-band to Ku-band frequency

- Mesh type: ATLAS knitting pattern, 18 OPI, gold plated tungsten wire

- Supporting network with triangle size of 250mm.

Highlights:

- 19.04.2016: Kick-off

- 16.11.2017: HRR

- 17.09.2019: MRR

- Q3/2020 (tbc): TRR

- 12/2020 (tbc): Delivery and contract close-out

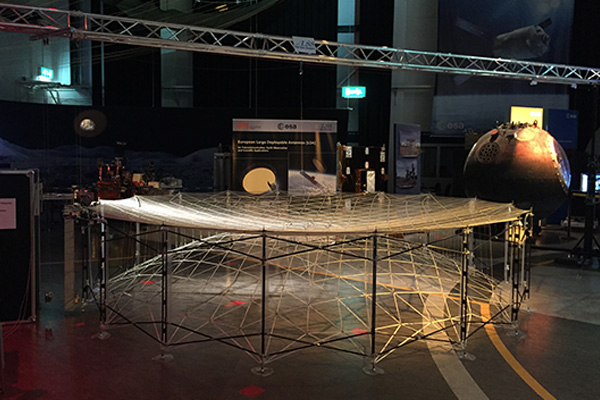

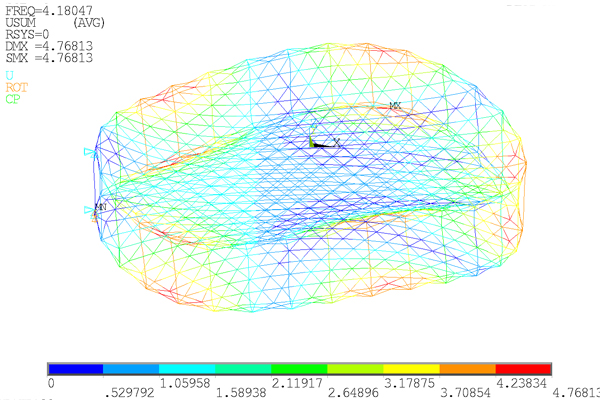

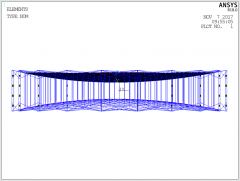

Deployable Reflector Concept (SCALABLE)

Description:

- Development project under ESA’s Technology Research Program

- Objectives:

- Development of a large deployable reflector concept, which is highly scalable and compliant for Earth observation as well as for telecommunication missions

- Extensive trade-off and selection of reflector architecture and deployable concept

- Testing of most critical items on breadboard level

- Realization of a 5m Engineering Model (EM) for C-band applications

- Start of metal mesh development

- Functional deployment and accuracy test campaign.

- Team: HPS Germany (prime contractor), LSS (subcontractor for reflector)

- Budget: 970 kEuro in contract to ESA

- Timeframe: 12/2012 – 12/2016

- End-TRL: 4-5 (depending on application)

Special thanks to

- Julian Santiago Prowald (Technical Officer at ESA), who is for us one of the initiators of the “European Solution of LDRS” and who contributed significantly to the creation of the reflector architecture.

- Leri Datashvili (CEO and Chief Designer of LSS), who is for us one of the most important fathers of large deployable reflectors (LDR) in Europe.

- Prof. Horst Baier (former lead of the Chair of Lightweight Structures at the Technical University of Munich), who enabled for many years research & education on and several pre-developments of LDRs at the University.

Features:

- Modular and scalable between 5 m and 20 m diameter (EM: 5m)

- Scalable up to Ka-Band (application for EM: C-Band, L-Band, S-Band)

- Target mass of reflector assembly: 25 kg (5 m) and 60 kg (12 m)

- LEO application for Earth Observation

- GEO application for Telecommunication

- Selected architecture: “double shifted pantograph“

(remark: this was the basis for all later LEA-products)

References:

- Live deployment at ESA/ESTEC on 23.11.2016; © ESA

LEA-X5 & European 5m X-band LDRS Completed

LEA-X5 & European 5m X-band LDRS Completed