November 2014

Successful HPS workshop on radiation shielding development

The European Space Agency has recently awarded HPS GmbH a GSTP-contract on “Evaluation of lighter and more efficient radiation protection for electronics and sensitive parts”. At the beginning of this activity a workshop took place bringing together European industries and institutes working in the field of radiation shielding for space applications.

The objectives of the workshop were to survey the state-of-the-art in shielding technology, review lessons learnt from previous projects and identify the future application areas and needs where more efficient shielding would be beneficial (e.g. for cost saving, mass saving, use of non radiation-hard parts etc.).

About 20 expertes attended and contributed to the workshop that was concluded very sucessfully. On this note, many thanks to the people shown below but also to the organisation assistants.

Attending entities were: Tesat-Spacecom, Max-Planck-Institute, OHB System AG, Fraunhofer INT, HPS GmbH, DLR, Technische Universität München (TUM), Thales Alenia Space Deutschland, Serenum a.s., ESA, STT-System Technik GmbH and HPS.

Key to Future Space-Com and Earth Observation: Large Deployable Antennas

Januar 2015

Under the auspices of the German ministry of economy and energy and DLR Germany had decided to entrust a team of SME-companies under the lead of RWTH-Aachen and several other highly renowned institutes with studies about mission profiles and potentials based on large deployable antenna (LDA)-applications, named SMERALDA (SME´s Radar and Large Deployable Antenna). HPS, the mid-sized antenna specialist and leading space-subsystem manufacturer, was responsible for the central LDA-part of the project that provided a respective concept for a small-scale-mission using a 5-meter LDA.

The study was successfully finished mid December 2014 and presented to a large audience at the German Space Agency in Bonn including to one of DLR’s directors Mr. Christoph Hohage.

Satellite Communications – Strategic Technology behind Germany´s Economy and Growth

April 2015

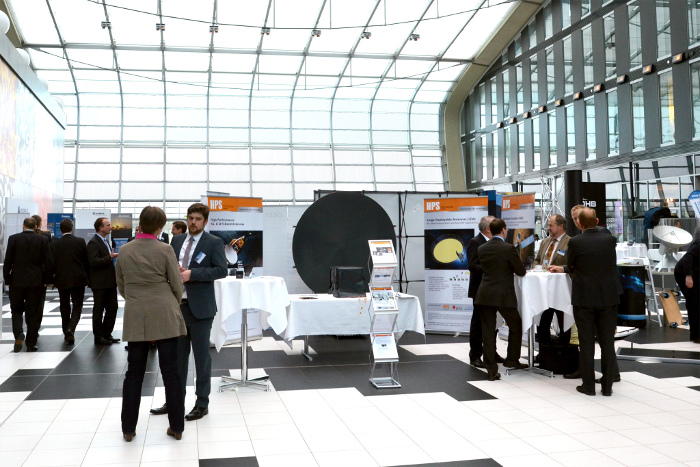

Practically no other space-technology provides so much impact on the future development of competitive knowledge- and information-societies like satellite communications. That is why the German ministry of economy and energy and DLR invited the leading companies in this field to the annual satcom-conference from March 25th to 26th in Bonn.

Prominently present among large system integrators (LSI) and small product suppliers (SME): HPS, the mid-sized antenna specialist and leading space-subsystem manufacturer. The Munich based R&D-division of HPS has welcome professionals at its attractive display centering around the company´s latest developments in the field of Q/V-band antennas, multilayer insulation (MLI) and large deployable antennas (LDA) and offered lectures about Q/V-band technologies at HPS as well as on its Ka-band antenna of Heinrich Hertz satellite.

Q/V-Band Feeder Link Antenna Successfully Tested

Mai 2015

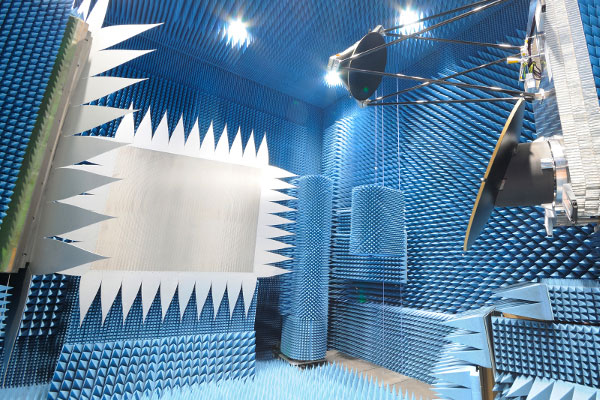

During May 2015 a large top deck feeder link antenna (Gregorian configuration, main reflector diameter: 1200 mm, sub-reflector diameter: 700 mm) working in Q/V-Band (Tx: 37.5 – 40.5 GHz, Rx: 47.2 – 50.2 GHz) has been successfully tested in the brand new RF Compact Range of the University of Applied Sciences in Munich.

HPS has developed this dual reflector antenna under contract to ESA since 2012. It was designed for European coverage, 8 gateways for nominal operations and 2 gateways for diversity sites. The reflector design is based on HPS’s Q/V-Band technology initiated in 2003 and flying on the German satellite Heinrich Hertz. The RF test has been performed under the lead of Prof. Fasold, a world wide acknowledged Antenna test expert.

Integration of Multilayer Insulation for Flight onto Mars Finalized

July 2015

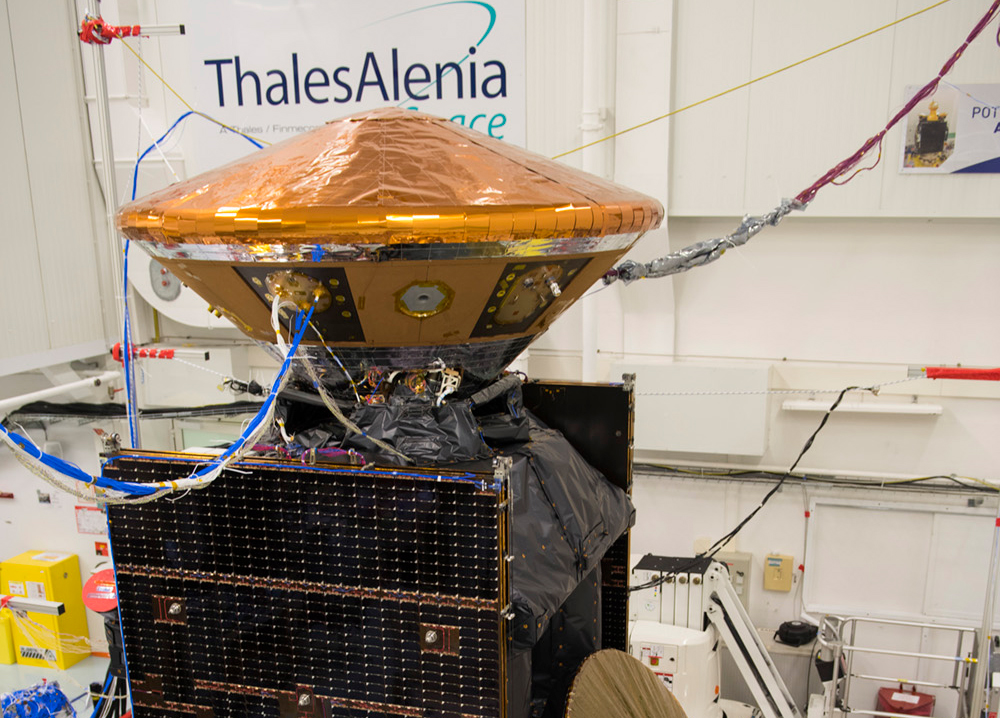

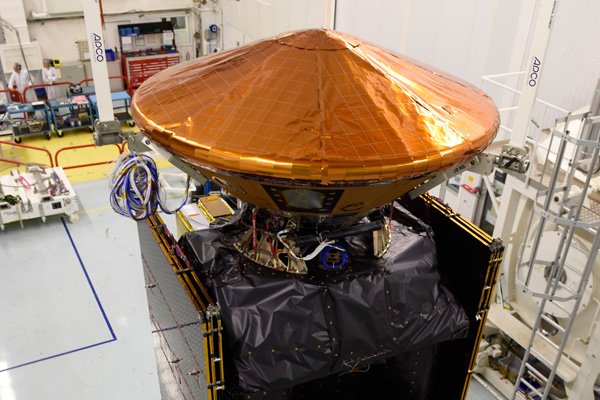

In January 2016, ESA launches the space mission ExoMars on its way to Mars. Arriving 9 months later in the Mars Orbit, the “Entry, Descent and Landing Module” (EDM) will separate from the mother ship and will land on the surface of Mars.

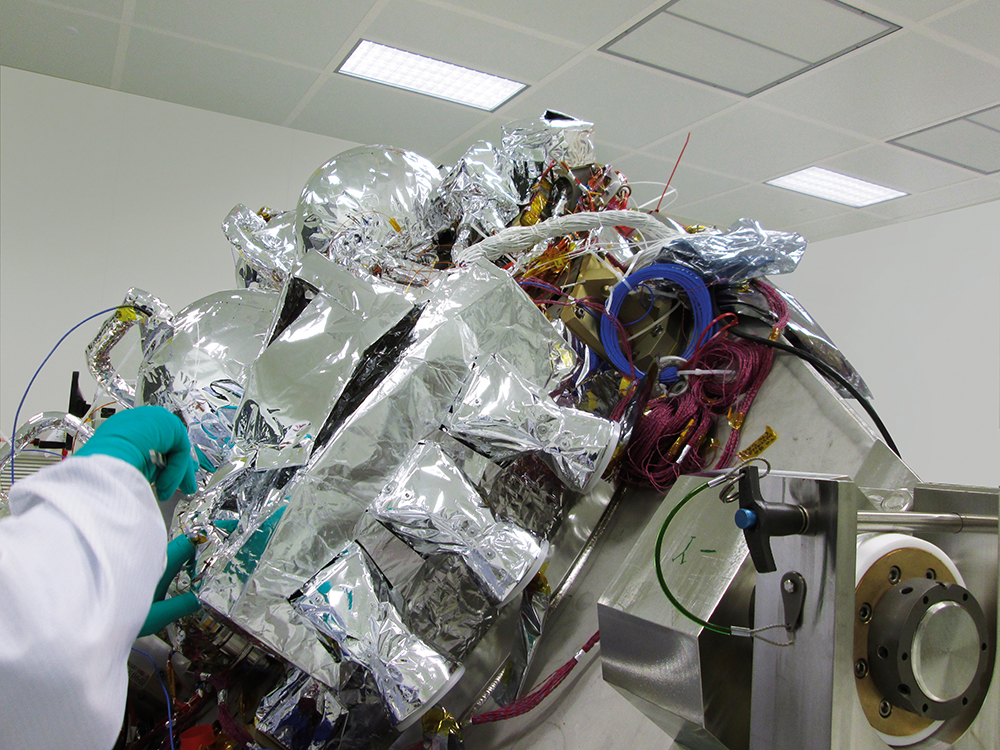

HPS Group received the contract for the complete Multilayer Insulation for the EDM-Lander in 2012. All internal and external blankets, ranging from tank-MLI, high temperature thruster MLI, standard tube MLI up to TPS-attached MLI, have been developed and manufactured by HPS Portugal until beginning 2015.

In plenty different integration campaigns during day and night, on site of the Customer ThalesAleniaSpace, Italy, HPS successfully attached more than 150 sheets directly on the flight hardware.

In April 2015 the whole spacecraft has been vibration tested under control of ESA.

And now, in July, HPS finalized its service with the last MLI AIT activities.

All HPS staff is proud to fly to Mars soon and thanks its Customers TAS-I and ESA for their trust in our capabilities.

For Further information on the ExoMars Mission, please click here: http://exploration.esa.int/mars/46124-mission-overview/

Ready for Mission to Mars: ExoMars Orbiter and Lander Shiaparelli Shipping to Launch Site

December 2015

Critical Thermal Protection made by Europe´s MLI-expert HPS in Portugal and Germany

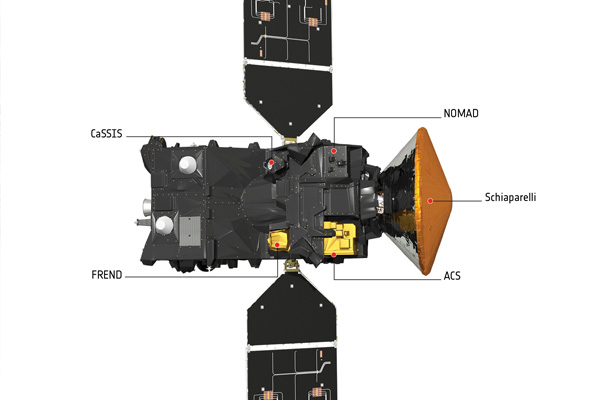

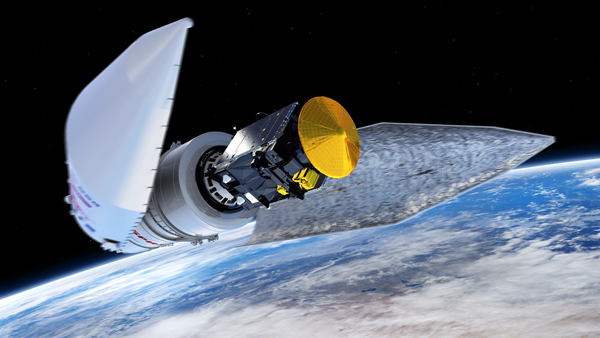

Scientists, media and other VIP´s from Europe´s space sector took the last chance on November 25th in Cannes to have a look at ESA´s latest exploration technology before it lands on Mars in October, 2016: Schiaparelli – an entry, descent and landing demonstrator module – is a technology-testing vehicle carried by the ExoMars Trace Gas Orbiter to demonstrate the capability of European industry to perform a controlled landing on the surface of Mars. The preparation for this mission enhances Europe’s expertise and enables the testing of key technologies which could be used in subsequent missions to Mars.

Although designed to demonstrate entry, descent and landing technologies, Schiaparelli offers a science package that will operate on the surface of Mars for a short duration after landing, planned to last approximately 2-4 sols (martian days).

Schiaparelli will be protected during its decend to Mars at a speed of 21,000 km/h as well as during its operations on the surface against all thermal impacts by a multilayer insulation designed, developed and manufactured by the Portugese space company HPS Lda.

„Thermal protection is one of the critical components that decide about success or failure of any space mission. However, with Schiaparelli it opens yet another dimension of human space exploration, since this spacecraft has the task to verify technologies for the generations of unmanned and finally human missions to land on Mars in future,“ said Ernst K. Pfeiffer, CEO of HPS. „In addition, my teams in Germany and Portugal have developed also the thermal protection for this mission´s scientific instruments CASSIS and NOMAD. All HPS employees in Germany and Portugal are extremely proud to serve as Europe´s selected thermal protection specialists in space, to have soon more than 10kg hardware on Martian surface and to play with this a vital part in man´s historic pathfinding mission to other planets.“

EUCLID-Assignment to HPS

December 2015

Antenna Reflector Assembly For Mankind´s Mission to See Whether Nothing is As It Seems

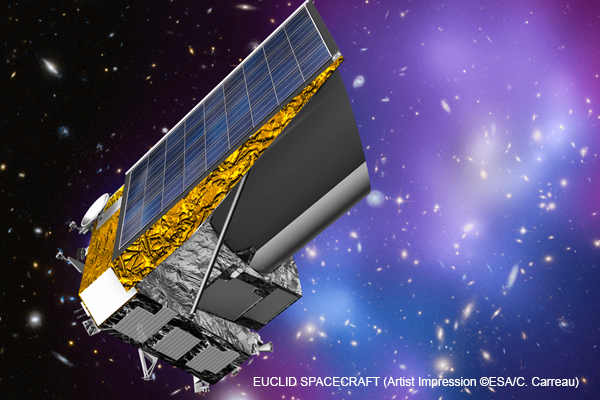

When in the first quarter of the year 2020 a Soyuz launcher lifts off heading for space from the European spaceport in French Guiana it will carry a very precious payload: EUCLID, the satellite on the hunt for dark energy which is supposed to be the force behind the acceleration of the universe´s expansion. An invisible force, nevertheless dominating the universe to the extent of about 70 percent – as it seems, while matter we can see makes up for only about five percent of everything that we want to know.

Thales Alenia Space has been selected as ESA´s prime contractor for the spececraft, while Airbus Defence and Space provides the payload module. Due to the outstanding characteristics of high performance structures made by HPS in terms of RF-reflectivity, minimized mass as well as thermo-elastic distortions HPS was selected by TAS (Spain) on December 4th to provide the high gain antenna reflector structure, from which all high resolution pictures of that mission will be transmitted to Earth. The engineering center of the German space-SME in Munich will design, develop and test the product, will overlook the production of structures at INVENT GmbH, Braunschweig, of the multilayer-insulation (MLI) at its specialized subsidiary HPS lda. in Portugal, and of metal parts at SERENUM from the new ESA member-state Czech Republic.

Based on robust and intelligent technologies EUCLID will be stationed for six years at the Lagrange Point L2, 1,500,000 kilometers away from earth, on a mission to make us see beyond the seemingly.

Taking the Next Step in ESA´s Clean Space Initiative

March 2016

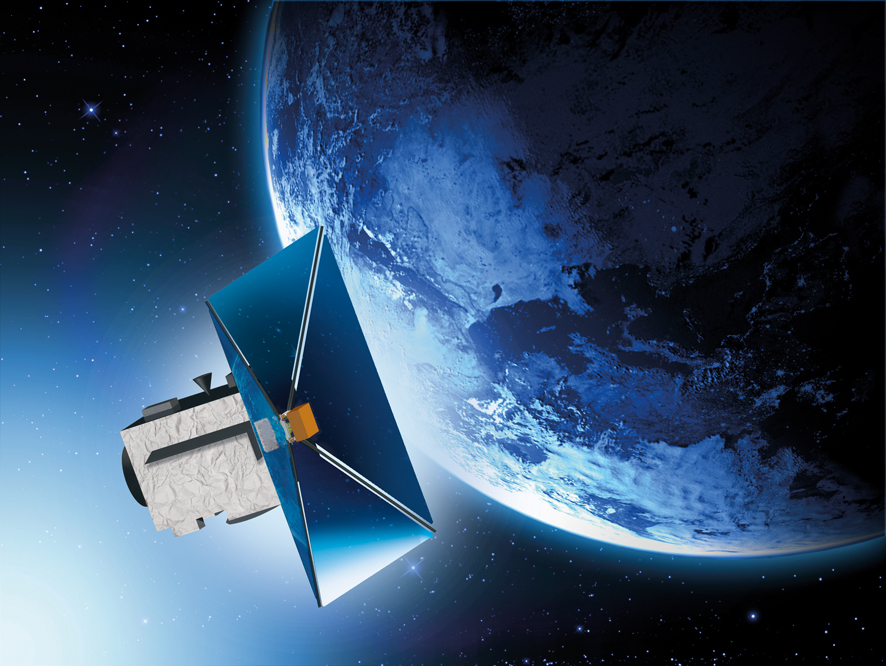

ESA-Prime HPS with SME-Consortium Ready to Build New Generation De-Orbiting Subsystem

Hardly any messages have dominated the space community´s discussions in the past two years as perseverently as these two:

- the debris from past satellite missions forms a growing threat to future endeavors in space

- the number of satellites expected to form future constellations especially on LEO is exploding since new players are discovering space as their domain

- which again multiplies the problem of future debris.

So, on the one hand enormous growth of the satellite business is to be foreseen, on the other hand this business needs better rules in order to be sustainable. „Clean Space“ is ESA´s answer in general and the quest for a new, fully ecological de-orbiting sailsystem in particular.

While currently satellite manufacturers are already facing problems to comply with the 25-years-deorbiting „guideline“ without minimising the effectiveness and increasing the cost of their missions, ESA now aims to make this period as a strict requirement leaving neither ecological nor economical footprints.

Capitalizing on previous research and development in this area like the precursor project ADEO, led by the subsystem prime HPS with its consortium of DLR-institutes in Bremen and Braunschweig and the SMEs Etamax and HTS, ESA now announced its expectations for a full fledged demonstrator ready to fly by 2018 with a deorbiting time of lower than 5 years. The new project will be ignited this year and ESA´s subsystem prime HPS is expected to take this next step towards the final breakthrough in deorbiting technology, too, because:

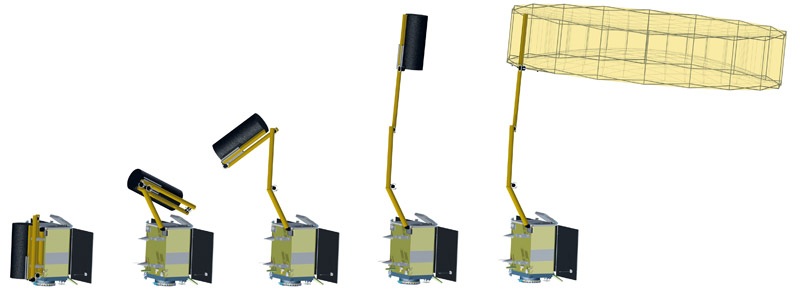

- the current HPS precursor project ADEO, featuring a 5m x 5m deployable boom and sail subsystem weighing just 20kg, has been successfully tested on breadboard level in February 2016 and will reach design maturity for an Engineering Model manufacturing and assembly through a CDR in these days in March.

- ADEO will then already fulfill the requirements of providing sail and boom materials able to withstand the very severe Atomic Oxygen (AtOx) and Ultra Violet (UV) environment, offering scalability down to 100-kilo-satellites down from the current reference case of spacecrafts at 1-1.5 tons of weight, and of providing reliable deployment technology tested under ambient conditions and in a vaccum chamber in mid 2016.

HPS as ESA subsystem prime is aiming at the follow-on project also with its proven partners.

In parallel and as leading specialist on deployable structures and antennas, HPS Germany acts as prime contractor for Large Deployable Antennas (LDA) in cooperation with the German SME LSS, while the HPS subsidiary in Portugal is working on a deployable highprecision mast system (10-20m) for instruments weighing 100-250 kg on science missions.

The Countdown is on: Exomars on its Way through Deep Space

March 2016

To reach and land on Mars in 5,296 hours

Guarded by its Multilayer Insulation made by HPS Portugal the European landing demonstrator Schiaparelli will reach and enter the hostile Martian atmosphere at a speed of 21,000 km/h by October 19th this year, after 269 days or 5,296 hours of flight through the galaxy after a perfect launch on March 14th.

Large Deployable Reflectors: Europe takes another step towards non-dependence in space technology

April 2016

Prime HPS selected to lead network of space-SME to success

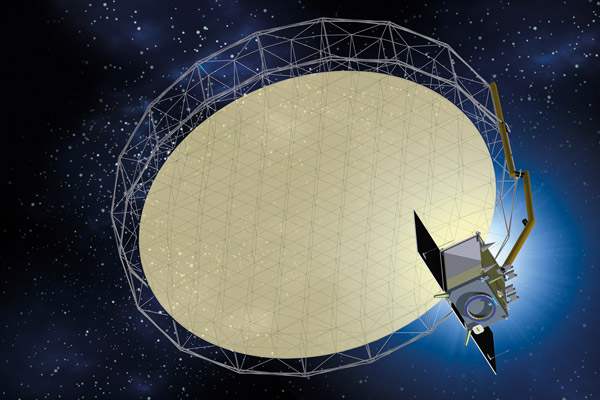

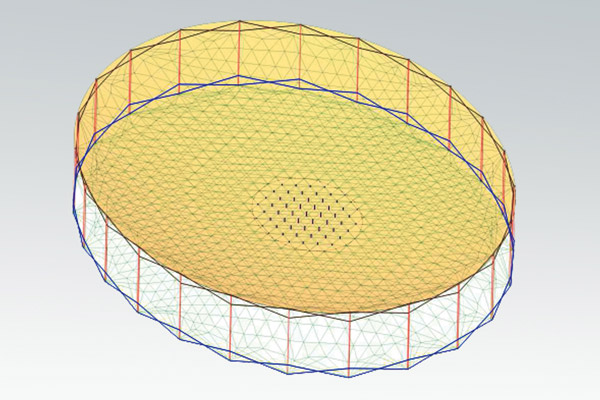

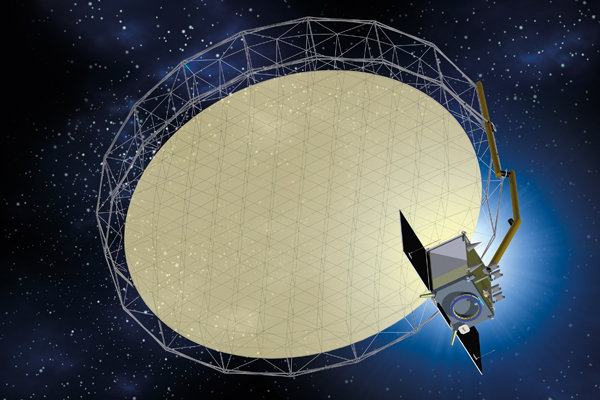

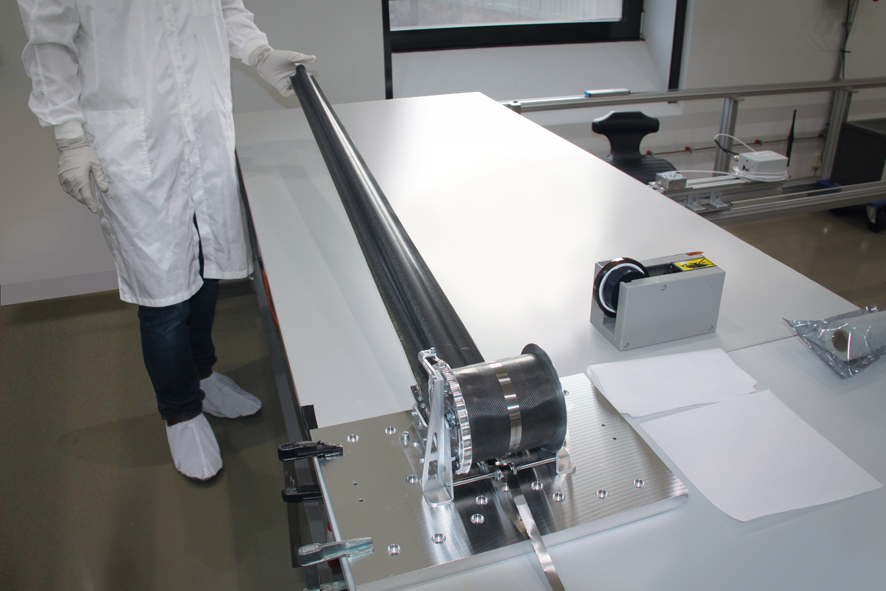

ESA has now awarded the contract for the development of „Mesh and associated carrying net for Deployable Reflector” (MESNET) to HPS. Kick-off for the project is scheduled May, 2nd, 2016.

Large deployable antennas and their respective reflectors are a critical asset in design and production of satellites for radar- and telecommunications missions like ESA’s BIOMASS and INMARSAT’s Alphasat. Until today, this technology is not available “as flight-verified” in Europe and still needs to be procured from American and Asian sources. But, Europe wants to play a role in that growing market of radar-oberservation and telecommunications satellites.

ESA has entrusted the functions of the subsystem prime to HPS Munich, while its Portugese subsidiary HPS lda, Porto, will be responsible for the assembly procedure and the actual assembly at a very high level of technology readiness (TRL).

In the context of the precursor study „SCALABE“ – to be concluded in summer 2016 – HPS also acts as prime contractor for the development of a 5-meter-demonstrator of a double panthograph deployable ring, which is being designed and built by HPS´Munich based collaborator LSS. Breadboarding of critical elements has already been performed by HPS in 2014/2015 and a mesh demonstrator has already been delivered by HPS for integration.

When in 2018 HPS will deliver the results of the MESNET-study – a vital element of ESA´s ARTES 5.1 technology program – the combination of both developments can result in a subsequent qualification model and finally in a flight model that could be ready as early as 2019/2010.

HPS-CEO Dr. Ernst Pfeiffer is confident, that Europe´s next step towards non-dependence in one of the most critical space fields will soon be taken: “The procedure to combine the capacities and outstanding abilities of specialized space SME under the prime and leadership of HPS is meanwhile a proven approach. We are certain that by 2020 ESA will be in the position to replace yet another position on the list of badly needed capabilities by `best of space`- technology made in Europe.“