CIMR-LDRS 8m-EQM Assembly-Story, Episode 2/12

October 2025

CIMR-LDRS 8m-EQM Assembly-Story, Episode 2/12

October 2025

Recapping the first episode of our 12-part series, the CIMR mission is multi-hundred million euro ESA mission to measure sea-ice concentration, sea-surface temperature, sea-surface salinity, and more.

Our focus in the groundbreaking mission, is the Large Deployable Reflector Subsystem (LDRS) – a combination of complex state-of-the-art technologies, built by the best minds across Europe.

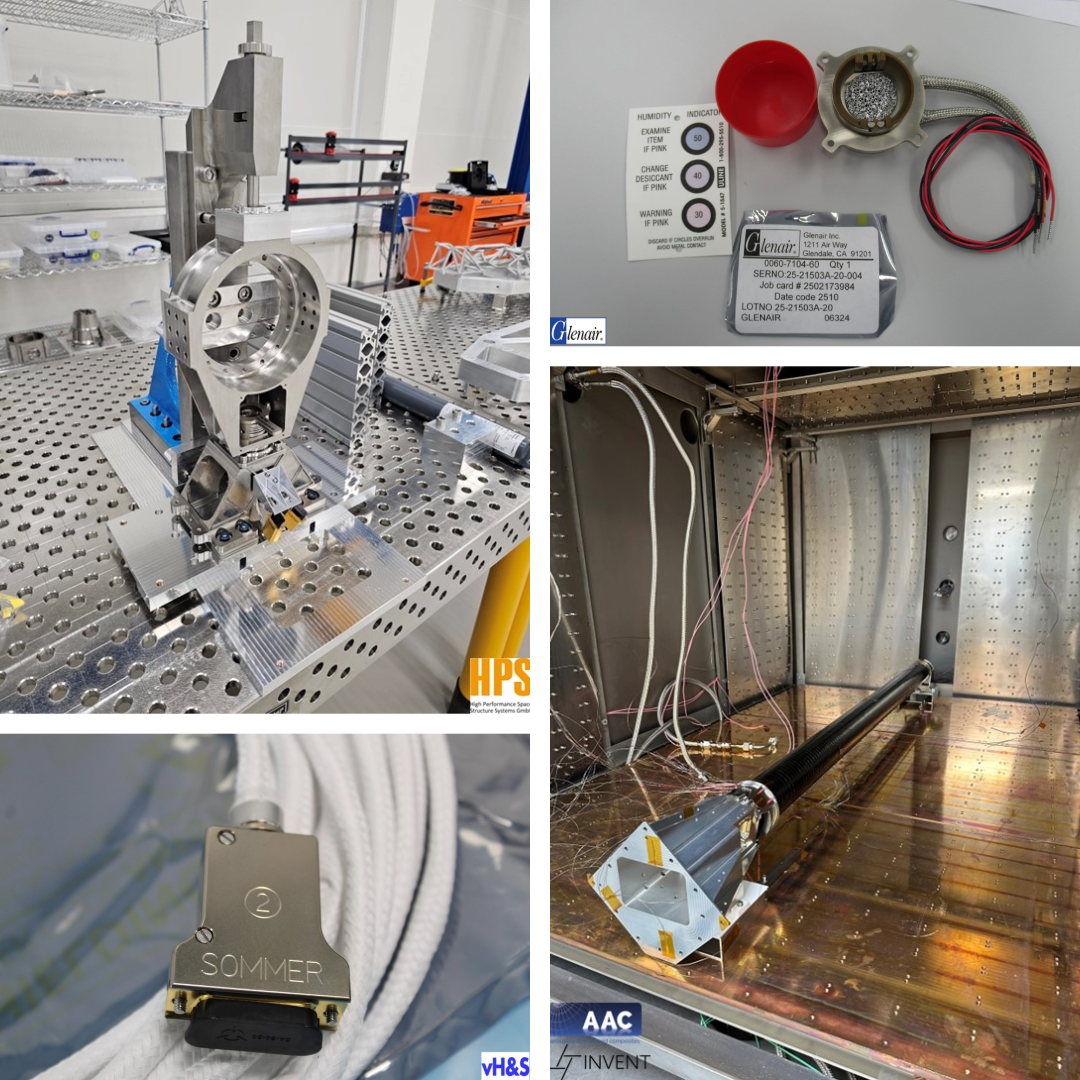

In today’s episode we will zero in on the day-to-day progress. Starting with the image on the upper right, release nuts from Glenair (which are used in HDRMs (Hold Down Release Mechanisms) to either keep space equipment stowed or to deploy it, have been procured and integrated into the HPS-Deployable Arm Isostatic HDRM (see upper left image). This isostatic HDRM will at some point be assembled onto the full DAA (Deployed Arm Assembly) of which one Arm Segment (see lower right image) has been through Thermal Vacuum Cycling at AAC in Wiener Neustadt (AT).

The lower left picture shows the arrival of the DRA harness built by VH&S (DE) at LSS premises (DE). This harness will connect the same Arm segment to the LSS-DRA (Deployed Reflector Assembly).

Stay tuned for more insider info as we observe and learn together how an ESA mission is realized.

HPS/LSS, 10.10.2025

CIMR-LDRS 8m-EQM Assembly-Story, Episode 1/12

September 2025

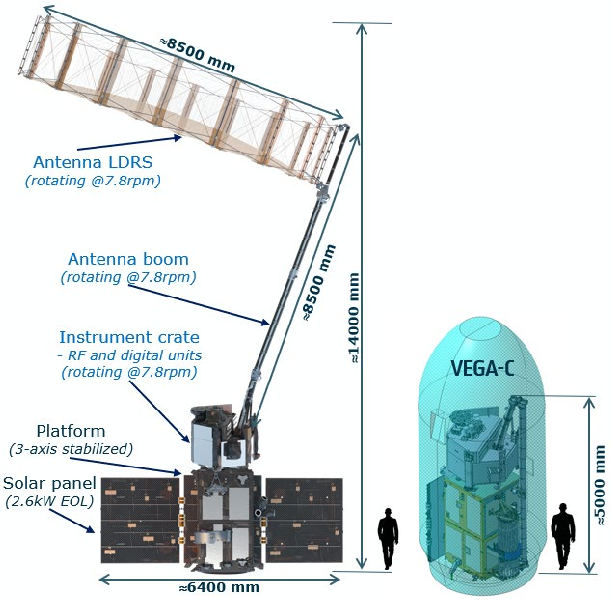

The goal is as ambitious as the means: technological non-dependence for Europe in space with a deployable reflector construction for high frequencies (Ka band) measuring eight meters in diameter on an equally deployable eight-meter-long arm, which rotates around its own axis eight times per minute in orbit. Extreme requirements: for example, an RMS (root mean square) value for surface accuracy that is to be considerably less than a few thenths mm over the entire 50 m2 reflector area, or a maximum permissible deviation of only 10 mm from the nominal value at the tip of the arm 8 m away, including vibrations, centrifugal force, and thermal distortions. Overall, the Large Deployable Reflector Subsystem (LDRS) consists of reflector, arm, deployment control electronics, harness, various hold-down and release mechanisms, and thermal hardware. This is the €120 million task of the LEA consortium (product name: Large European Antenna) of more than a dozen space companies, mainly SME, from eight countries led by HPS/LSS.

Now that the most difficult part, the coordination of the design and structural analysis between the large LDRS and the satellite, as well as achieving the “manufacturing readiness” of all components through countless process developments, has now been overcome, the “Engineering Qualification Models (EQM)” is now in the middle of production. We want to take you with us in a sequel story in 12 episodes.

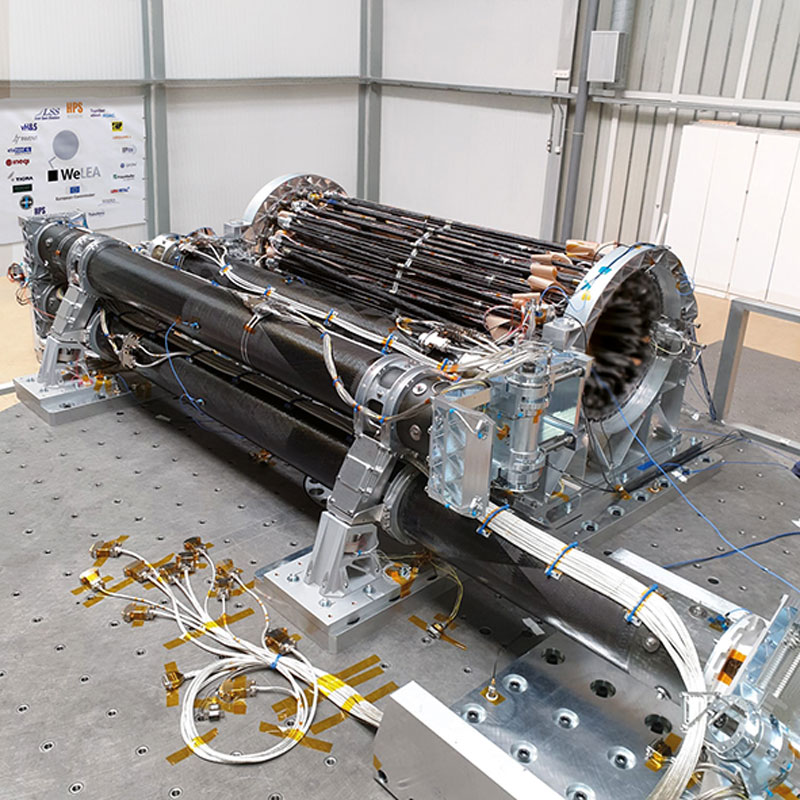

As a reminder in relation to our LEA-team: Munich-based LSS GmbH is responsible for the Deployable Reflector Assembly (DRA). The unique Ka-band gold-plated MESH for the DRA is developed by HPtex GmbH, located in the German textile-triangle in Upper Franconia (DE). The unique Ka-band MESH for the reflector is produced by HPtex GmbH located in the textile-triangle Upper Franconia, the 9m x 9m gold-plated EQM-Mesh (see picture) has already been produced. INVENT GmbH, Brunswick (DE), is supplying the carbon fiber reinforced tubes (see picture) for the 8-meter “Deployable Arm Assembly (DAA)”, the first EQM-segment is already under inspection. NanoSPACE AG, Switzerland is developing and producing the highly accurate and stable motor-driven hinges for the arm. INEGI Portugal has already delivered the 0-g ground test support equipment for the DRA to LSS, the final tests for the 0-g DAA-GSE are in full swing before delivery (see picture). HPS S.R.L., Romania is currently finalizing under great time pressure one assembly and transport ground support equipment (MGSE) after the other (see picture). HPS GmbH, Munich, as direct contractor of the satellite Primes ThalesAleniaSpace, Rome (IT), has the LDRS subsystem responsibility, as well as that for the deployment arm DAA.

When CIMR embarks on its mission aboard a Vega C in 2029 to observe ice sheets and snow from dawn to dusk in a sun-synchronous orbit, this will be a step forward in terms of critical technologies, as LDRS are also products for a range of military applications that can contribute to increased independent defense capabilities, important especially in these days.

Sequel follows.

HPS/LSS, 16.09.2025

Inspection of the HPtex-Mesh for ESA’s Next-Gen Earth Observation Satellite Successfully Completed

June 2025

After months of precision manufacturing at HPtex GmbH, a specialist in space-grade textiles based in Upper Franconia, Germany, a major milestone was reached on June 24, 2025, for the European space mission CIMR (Copernicus Imaging Microwave Radiometer). A large-scale inspection of the mission’s deployable antenna mesh took place in the newly commissioned cleanroom assembly hall at HPS headquarters in southern Munich.

At the heart of the event: the newly developed Universal Space Mesh USM TUCH 32 – an ultra-fine metallic mesh tailored specifically for CIMR’s demanding Ka-band requirements. Available in two variants (20 µm and 25 µm wire diameters), this mesh features E32 needle fineness (32 needles per inch), an exceptionally low mass of approximately 40 g/m², and dimensions of 10.2 x 9.5 meters – making it one of the largest high-performance space meshes of its kind worldwide. The individual mesh stripes were sewn by HPtex with its reengineered sewing machine in a now fully automated and touchless sewing process. Thanks to the large knitting width (over 4 m) of the in-house high-performance knitting machines only two seams have been necessary to assembly this large mesh.

The mesh itself is woven using high-purity wire from LUMA WIRE TEC in Sweden, a long-standing partner of HPS and HPtex.

The inspection was attended by a top-tier delegation, including representatives from:

This milestone marks the culmination of four years of dedicated development under the CIMR program, building on six prior years of preparatory research and prototyping. Over the course of the project, hundreds of mechanical tension tests were conducted—primarily using HPS’s proprietary testing setup, which has been steadily refined over the years. In parallel, hundreds of RF tests were carried out, culminating at ESA/ESTEC, using their cutting-edge, high-precision RF characterization facility, to fine-tune the mesh’s electromagnetic properties. Cyril Mangenot, former RF specialist at ESA/ESTEC and one of the earliest supporters of a European LDRS solution on the agency side, supported the mesh development for HPS with all his experience.

The next step: mating the mesh with the Engineering Qualification Model (EQM) of the cable network provided by LSS. CIMR is currently in Phase C/D, with the Critical Design Review (CDR) scheduled for the first half of 2026.

This achievement exemplifies the strength of European collaboration in space technology. From materials science to RF performance, every aspect of this “dream team” effort—including ESA, TAS-IT, HPS, HPtex, LSS, and others—has contributed to an outstanding result.

HPtex is now the central European source for supplying high-performance space meshes to customers across the globe – from the Americas to Asia – and demonstrates once again that world-class aerospace innovation is alive and thriving in Bavaria.

CIMR-LDRS: The lighthouse project for non-dependence in European space travel enters the production phase of the qualification model (EQM) as planned

April 2025

Long before an unspeakable bloodbath sealed the end of peaceful life in Eastern Europe in 2022, the demand for technological “non-dependence” had already conquered a top position among the strategic priorities in German and European space travel. The focus was particularly on large reflector antennas that could be deployed in space, suitable for missions of all kinds.

The history of this German technology for Europe began more than a decade ago with SCALABE, a technology development funded by ESA, and SMERALDA (SME’s Radar and Large Deployable Antenna), a study funded by the German Space Agency with significant participation by antenna specialist HPS GmbH. Through further technical chapters of successful concretization of the goal with significant support from ESA and the EU, the Munich-based company finally led a consortium of mostly medium-sized partners from eight countries to the spectacular win of the 115 million euro contract from Prime`sThalesAlenia Space (TAS) for “CIMR LDRS” (Large Deployable Reflector Subsystem) in 2020: the world’s largest rotating deployable reflector antenna construction for the EU’s Copernicus Imaging Microwave Radiometer (CIMR) lighthouse project for observing land, ice and oceans, particularly the Arctic, from space under the management of the European Space Agency (ESA). The LDR subsystem consists of a reflector, arm, deconvolution electronics, cabling, various hold-down mechanisms and thermal hardware.

After a long design phase and intensive iteration with the direct customer TAS in Rome and the end customer ESA, the go-ahead was given in phase C/D with the completion of the first so-called “Manufacturing Readiness Review” for the construction and testing of a qualification model (Engineering Qualification Model, EQM). In these days of spring 2025, HPS has now finally entered the intensive phase of manufacturing the EQM.

Challenges on the way to new shores

The technical challenges were and are immense, as the goal is nothing less than a deployable reflector construct for high frequencies (Ka-band) with a diameter of eight meters on an equally deployable eight-meter-long arm that rotates around its own axis eight times per minute in orbit. This results in extreme requirements such as an RMS (Root Mean Square) value for the surface accuracy, which must be much smaller than 1/10 mm over the entire 50 m² reflector surface, or a maximum permissible deviation of the 8 m distant arm tip of just 10 mm from the nominal value, including vibrations, centrifugal force and thermal deformations.

The challenges of managing the various aspects of the project were and are no less demanding. The program management of the CIMR team from ESA and TAS has played a prominent role from the outset, while HPS GmbH, known for its heritage in institutional, military and commercial antenna construction – in addition to its own development work at arm and subsystem level – is responsible for managing the consortium of around a dozen SMEs, including such outstanding innovation drivers as Munich-based LSS GmbH for the deployable reflector assembly (DRA), based on a highly successful, long-standing development partnership. The lightweight carbon struts for the DRA come from the former Portuguese HPS subsidiary and now FHP, INVENT GmbH contributes the carbon fiber-reinforced tubes for the 8-meter deployable support arm (DAA), NanoSpace Switzerland develops and produces the high-precision yet stable, motor-driven joints of the arm, HPS Romania and INEGI Portugal the constructions for ground tests and transports (“MGSE”). In addition, HPS is responsible for providing the central element for the deployable reflector: the measurably best Ka-band MESH from HPtex that is available to buy in a 9m x 9m size – and, as a “made in Germany” product, transforms European non-dependence from vision to reality. Until then, a MESH in such dimensions had only been available in American production. Originally planned as an essential element of the German-European supply chain for CIMR, the joint venture HPTex GmbH (JV of Iprotex GmbH & Co. KG and HPS GmbH), founded in 2020, now sells its mesh products worldwide, especially in Asian and continental American countries. The EQM mesh for CIMR recently came out of HPtex production.

The most important components (DAA and DRA) will be ready by the end of the year, and the series of tests will begin early in 2026.

“If you want to be ahead, you shouldn’t be afraid of the unknown” (Ernst K. Pfeiffer)

When CIMR sets off on its mission in 2029 on board a Vega C in a sun-synchronous orbit to observe ice sheets and snow, among other things, from dawn to dusk, Europe will not only benefit from the knowledge gained from the project, but also from the certainty of having mastered the step towards technological LDRS independence. LDRS are also products for a range of military applications that can contribute to an increased defense capability, especially in these years. HPS CEO Ernst K. Pfeiffer sees this as a milestone that goes far beyond the immediate success of the project: “This space project is clear proof that the mentality of all those involved in the project – both industry and institutions – is completely different to the risk aversion that the public normally attributes to Germany in particular, and to some extent also to ESA. Not being afraid of the unknown is the first key to success. Way up front is where it´s getting dark. Especially in space. But not only there.”

January 2023

Since the spectacular win of the €110 million contract in 2020 for the development and construction of an LDRS (Large Deployable ReflectorSubsystem) by the SME consortium led by HPS, the project supporting to secure a sovereign European level of innovation has been running like on rails despite all its complexity. The confidence of the end customer ESA and its prime contractor TAS-I for the mission, which has grown steadily over the course of the project’s development, has now found expression on 23.01.2023 in the sealing of the departure into Phase CD by the signing of the so-called “RIDER” for the construction and testing of a qualification model (EQM) in 2023/2024, followed by no less than two flight models (PFM and FM2).

The supporting technology pillars of the innovation project are, in addition to the main innovation partners LSS (development, construction and test of the large deployable reflector), the HPS subsidiary HPtex (mesh production for the reflector), FHP (CFRP struts for the reflector), INVENT (CFRP tube for the deployable arm) and vH&S (for the deployment control electronics), further 10 companies from seven European countries under the consortium leadership of HPS.

The Environmental Observation Mission under the Copernicus Earth Observation Program of the European Union is an essential element of the European Space Strategy as a highly ambitious project in the field of climate observation and the understanding of effects of climate change.

Photo (TAS-I): contract sealing – center: Massimo Camparini (CEO of the space company ThalesAleniaSpace Italy) and the CEOs of HPS, Ernst K. Pfeiffer (right) and of LSS, Leri Datashvili.

Juli 2021

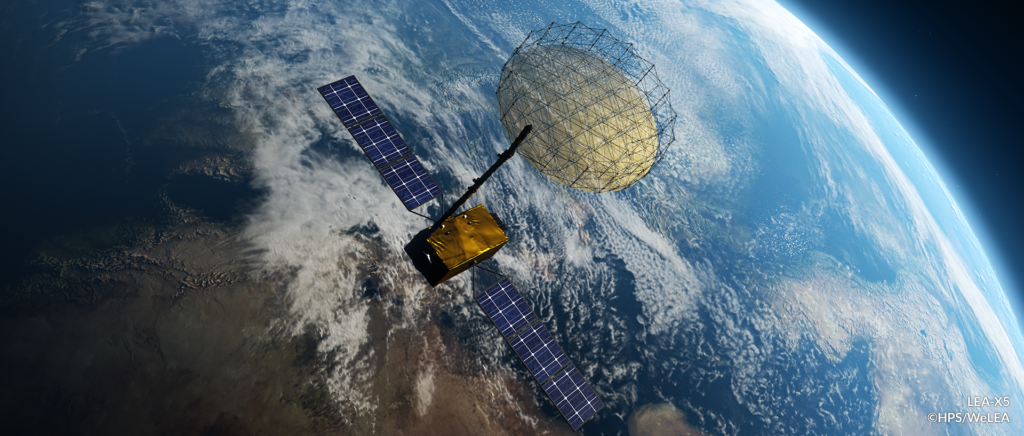

Gladly we announce with a new 20-minutes-movie the completion of the H2020-development „LEA-X5“, the 5m class European Large Deployable Reflector Subsystem (LDRS) operating in X-band.

The film itself is of course showing recent environmental and deployment tests, but it is mainly about PEOPLE, who are space engineers and space enthusiasts, and what they can achieve with combined powers and brains. These people, together with the enablers European Commission and European Space Agency, are making the achievement of „European Non-dependance“ happen.

LEA-X5 is a full LDRS-Subsystem (lead by HPS, Germany) and comprises the

Further partners of the H2020-consortium have been: INVENT (DE), FHP (PT), INEGI (PT), TICRA (DK), LUMA (SW), HPTEX (DE), ARQUIMEA(SP), HPS (RO), ETAMAX (DE), WSS (DE), ONERA (FR), TAS (FR), OHB (DE), Airbus (DE).

Most of the consortium members are introduced in the movie, inluding many interviews.

Take your time and enjoy the spirit of doing big things: LEA-X5 – European 5m X-band LDRS Completed (Final Report 06/2021) – YouTube

Best regards,

Your WeLEA-Consortium

March 2021

With the successful test of the Deployable Assembly Arm (DAA), which connects a Deployable Reflector Assembly (DRA) to the satellite, just completed at INEGI, the European LEA consortium led by HPS has cleared the next hurdle in the technical realization of Europe’s new antenna technology.

The 5m long DAA consists of 3 hinge mechanisms and 2 HDRMs (both by RUAG Space Germany), Release Mechanisms (by Arquimea, Spain), three CFRP tube segments (by INVENT, Germany), Metal Fittings (partly by HPS Romania), Deployment Control Electronics & EGSE (by von Hoerner & Sulger). Focus of the tests have been the verification of a) the functional full deployment (which takes in total 25 min.), b) a high pointing accuracy of the arm and c) the verification of the mathematical thermo-elastic models.

INEGI (Portugal) is the main partner for the arm deployment test and a good partner of HPS for over 13 years now. INEGI was responsible for the 0-g-simulation Test Stand and the Thermo-elastic Distortion Test Stand. Despite the pandemic and all restrictions the teams could manage this progress with highest motivation and closest possible contact between the INEGI/HPS team on-site in Porto and the HPS-engineers in Germany. HPS is responsible for the DAA and also for the implementation management of the whole LEA-activity. The total LEA-team encompasses 15 partners from 7 countries; the program started in the framework of H2020 in November 2017. The arm deployment test and the TED-test (thermo-elastic distortion) was one of the last tests of this H2020 activity.

The next step – starting still in March – is the environmental test (vibration and thermal vacuum) of the full LDR-Subsystem (Reflector, Arm and HDRM, all connected), which will be performed at INTA in Madrid, Spain.

“LEA-X5” (5m reflector diameter, 5m arm length, X-band application for Earth Observation and Telecommunications) is meanwhile seen as one of the precursing technology developments for the current Copernicus CIMR Mission.

March 2021

Fifteen companies – mostly SMEs – from seven countries and one goal: a deployable 5-meter X-band-antenna as a preliminary development for the CIMR project, developed under the European H2020 program (2017-2021). For the first time ever, such a complete subsystem (HPS) has now been successfully assembled in Europe from the reflector- (LSS) and arm- (HPS) assemblies. Previously, the test deployment of the arm and reflector – each individually – had already been successfully passed.

LEA-X5-Subsystem is now at the premises of the consortium´s highly reliable test partner INTA in Spain, where vibration tests for the subsystem are on the agenda in the presence of the LSS- and HPS-teams. In a third round of testing, the subsystem will have to prove itself capable of withstanding the conditions of the thermal chamber.

The next complete subsystem-hardware in this context – the CIMR LDRS-EQM – will be assembled end 2023.

With the key technology behind LEA-X5, the continent is decisively expanding its independence from non-European sources.

October 2019

Dear Friends and Fans of Europe in Space,

in the name of all members of our pan-European WeLEA-consortium we proudly present a video, documenting the successful road of the development of one of the most needed critical technologies in space: the Deployable Large European Antenna (LEA).

Invented, designed, tested and manufactured by more than 15 well known space companies from 7 European countries with a total staff of more than 500 dedicated specialists, representing a truly unique team of SMEs and Midcaps, the LEA-product is now taking shape as nothing less than “A European Declaration of Non-dependence in Space”.

Thanks to the farsighted vision of both powerful institutions responsible for our continent´s future in space, the European Space Agency ESA and the European Commission EC, LEA will become an invaluable technological asset to blaze our own trail towards knowledge and understanding as indispensable prerequisites to making this world a sustainable, better place – for life in diversity, for all citizens on the globe, and for one Europe across all its internal borders.

Within the WeLEA consortium HPS Germany, as prime contractor, is responsible for the project- and technical management of the whole LEA-subsystem, the deployable arm assembly and the reflective metal mesh.