July 2021

Spaceborne: ADEO-N2 Dragsail Testmission „Show me your Wings“ on Orbit

Falcon 9 rocket successfully deploys innovative technology to keep space sustainably clean

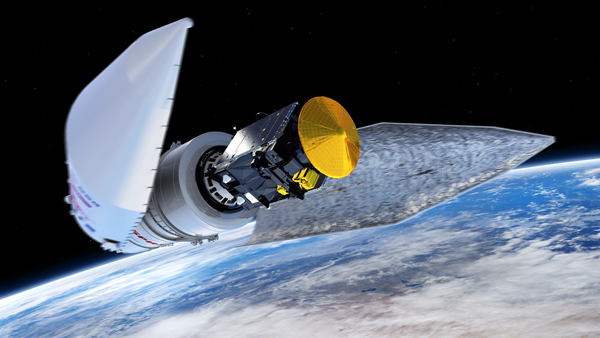

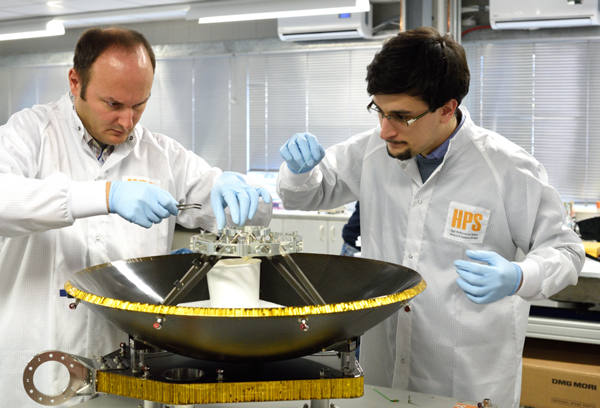

On Wednesday, June 30, at 21.31 hrs CEST a Falcon 9 by Space X took off to a transporter 2-mission from legendary spaceport Cape Canaveral, Florida. On board: Italian NewSpace company D-Orbit´s ION Satellite Carrier on its „Wild Ride“-mission with tech-passengers from 11 countries, among that HPS’s ADEO-N2, named „Show me your Wings“. ION was successfully separated from the launcher exactly one hour after liftoff.

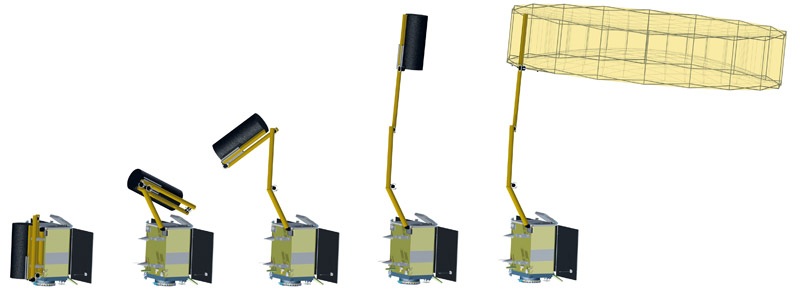

The ION-platform itself will now seperate one payload after the other on their respective orbits for in-orbit validation tests, until finally the platform turns into a test object itself, since it will be brought back „home“ by ADEO, the world’s only industrial NewSpace drag sail of its kind for the multiple accelerated return of retired satellites. The idea behind it: „Just keep space „cleangreen“ by launching only what you have equipped with a device to bring it quickly back home after use“, says Ernst K. Pfeiffer, CEO of German spacetech company HPS. ADEO is available from HPS in different versions tailored to the size and weight of the spacecraft in question. In this case, it is one of the smallest versions, weighing just 800 grams, with dimensions of only 10x10x10 centimeters and a sail area of 3.6 square meters.

HPS CEO Ernst K. Pfeiffer is convinced that ADEO came at exactly the right time to promote sustainable NewSpace development by avoiding the threat of apocalyptic space debris scenarios, despite rapidly growing constellations. In this context, Pfeiffer emphasizes the excellent R&D support provided by engineers and test facilities of the DLR Institute of Space Systems in Bremen, as well as the various economic development support contracts and grants provided by ESA, DLR and the Free State of Bavaria.

The implementation of the technology developed by HPS’s NewSpace Team at Munich headquarters was largely supported by the hands of engineers and technicians of the Romanian subsidiary and Romanian workshops. This is now, according to Pfeiffer, „our clear advantage having all in one company: heritage from institutional space, a tailored „internal start-up department“, a steadily growing house in Bucharest and several trustful development and production partners. New and expanded challenges to innovation and manufacturing are already waiting.“

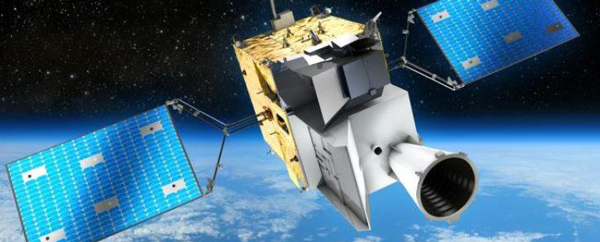

At the end of the nominal ION-mission, in front of its “eyes” of the integrated cameras, the ADEO braking sail module unfolds, shows its „wings“ and leads ION to residue-free disposal by incineration in the atmosphere much quicker than without the sail. The first 100 km of descent will be monitored intensively. This is planned to happen in a mission slot between December ´21 and January ´22. This mission now is the last verification in a series that also encompasses a first flight on Rocket Lab´s Electron in 2018 and several parabolic flights until 2021.

With this inflight-proof of maturity ADEO is targeted to go then into serial production for customers already waiting in the U.S., Europe and Asia.

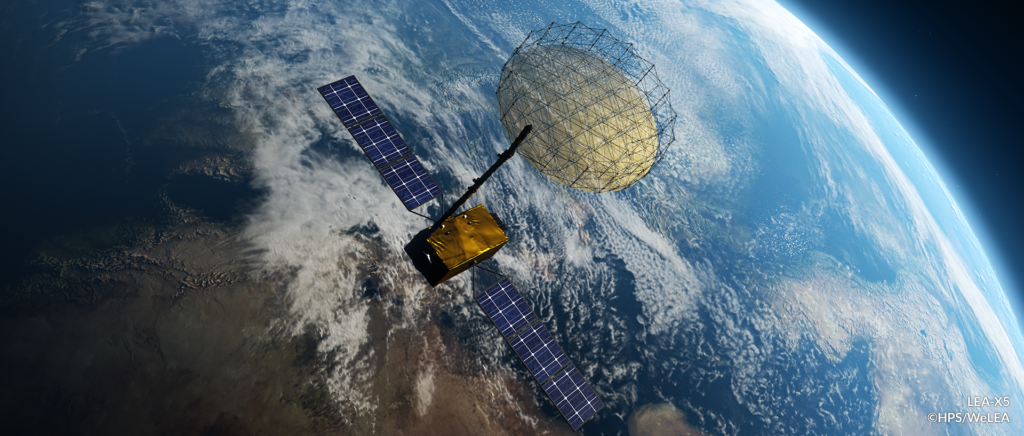

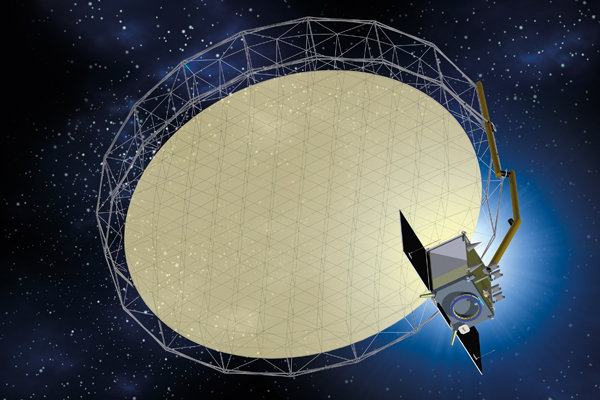

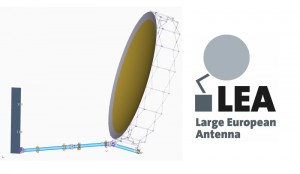

LEA-X5: New Movie on the completion of the European 5m X-band LDRS

Juli 2021

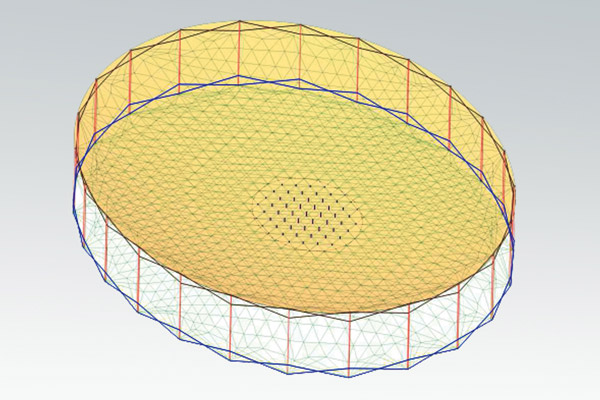

Gladly we announce with a new 20-minutes-movie the completion of the H2020-development „LEA-X5“, the 5m class European Large Deployable Reflector Subsystem (LDRS) operating in X-band.

The film itself is of course showing recent environmental and deployment tests, but it is mainly about PEOPLE, who are space engineers and space enthusiasts, and what they can achieve with combined powers and brains. These people, together with the enablers European Commission and European Space Agency, are making the achievement of „European Non-dependance“ happen.

LEA-X5 is a full LDRS-Subsystem (lead by HPS, Germany) and comprises the

- 5m diameter X-band reflector assembly (lead by LSS, Germany)

- the 5m long deployable arm assembly (lead by HPS, Germany),

- hinges & HDRMs (RUAG, DE),

- deployment electronics (vH&S, DE),

- thermal hardware (HPS/FHP).

Further partners of the H2020-consortium have been: INVENT (DE), FHP (PT), INEGI (PT), TICRA (DK), LUMA (SW), HPTEX (DE), ARQUIMEA(SP), HPS (RO), ETAMAX (DE), WSS (DE), ONERA (FR), TAS (FR), OHB (DE), Airbus (DE).

Most of the consortium members are introduced in the movie, inluding many interviews.

Take your time and enjoy the spirit of doing big things: LEA-X5 – European 5m X-band LDRS Completed (Final Report 06/2021) – YouTube

Best regards,

Your WeLEA-Consortium

EUCLID: ESA-Project to Search for Dark Matter and Energy takes Crucial Step

December 2017

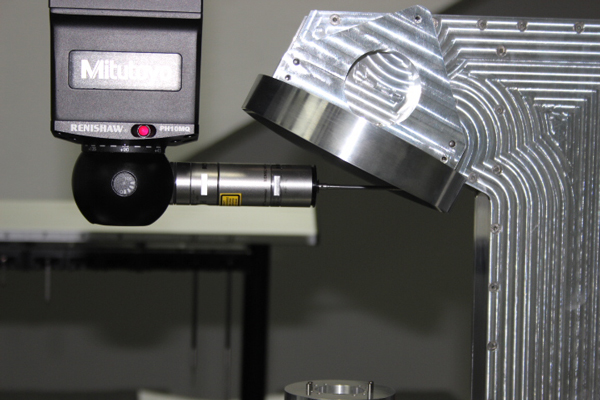

HPS Germany receives STM-acceptance for first model of the central antenna unit

European HPS-Group first Enterprise to Receive EN 9100:2016-Certification

July 2016

Quality first beyond borders

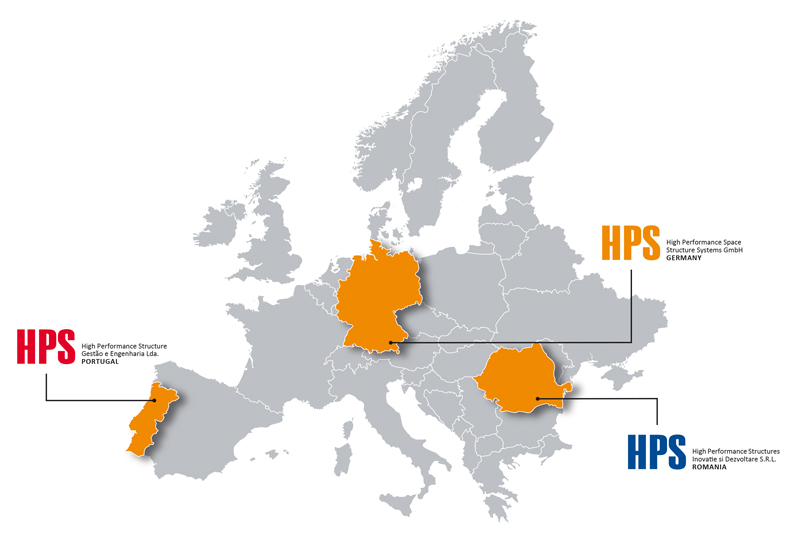

Letterheads, websites, publications: The claim of the midsize European space company is everywhere: „HPS – The Team to Trust“. Since June 27th now, this claim is even officially backed by the award of the first certification according to the strict rules of the brandnew „DIN EN 9100:2016 Aviation, Space, and Defence Quality Management Services.“ Not only that HPS, headquartered in Munich, is the first company ever in Germany to receive this high ranking confirmation – it is also a breakthrough for the whole group, because the certificate covers all of its three European group members, in Germany, in Porto (Portugal) as well as in Bucharest (Romania).

The certification was performed by the certification body AirCert GmbH, based in Ottobrunn near Munich (www.aircert.org), operating all over Europe and even overseas and in the far East. AirCert has specialized for the high end aerospace business and consequently made a big effort to be one of the very first entities in Germany to become authorized by international authorities for the new EN9100:2016 standard.

While the certification audit took seven working days to clearly review that the space group guarantees the same highest possible quality-management at all sites beyond borders, the preparations for this next great step after the certification of HPS in Germany and Portugal according to the 2008-rules of ISO 9001 took more than one year and an investment well above 100,000 Euros. The new EN9100 certification rules are by far more detailed and specific about the specification of core processes, traceability of supply chains and working processes, strict in the area of management processes and explicit about the requirements on key performance indicators, facilities, tools, and equipment as well as on awareness and compliance – the latter bearing the undeniable proof that the European space business world can serve as a shining example of sharing the same values when it comes to serving the customers with quality first.

„HPS- The Team to Trust“ – rarely has a space company´s communication claim been more seriously substantiated.

VIP-Delegation Visit to HPS

October 2015

On September 30th, HPS welcomed a VVIP-delegation of German and Bavarian space policy at its HQ-premises in Munich. Dr. Gerd Gruppe, head of space management and member of the executive board of DLR was accompanied by DLR´s head of SME-policy, Uwe Soltau, and Bernd Buchenberger, Senior Manager space and aerospace at the Bavarian ministry of economy.

Munich as well as Berlin pay special attention to the sector of space-SME, since SME are expected to serve as pacemakers in the first front of technological innovation. In this respect, space-tech expert HPS is especially in focus, since the company is the only German SME with a subsidiary in Europe representing today the long vacant position of the „M“ in space-SME. In addition, its managing director and owner Dr. Ernst Pfeiffer acts towards politics and business as spokesman of all German space SME organized in the AKRK-Committee.

Accordingly, the delegation was especially interested in the company´s new ready-to-market products – innovations which play a vital role in the German space agency´s new „component initiative“ – as well as in first hand information about important aspects of international cooperation like between HPS Germany and its subsidiary HPS Lda., Portugal.

Dr. Gruppe personally pushes the German „component initiative“ with high priority in the firm belief that the German space industry urgently needs to define its own answers to challenges arising from the advent of completely new players like Google on the hitherto „closed shop market“ of space technology. According to Gruppe, „components“ form the central element: small, serially produced, very cost effective, and innovative units which more than ever before allow space to become an integrative and pacemaking part of daily life in business and society.

Together with HPS shareholder Sigrid Klett, former co-owner of the Munich based space company Kayser-Threde, Ernst Pfeiffer introduced the latest HPS-developments, like

- the rapid deployable ground antenna URDA for high-rate data transmissions; the antenna can be carried and operated even offroad by just one person

- an innovation with highest potential for serial production with a spectrum of target customers ranging from TV-correspondents to civil safety and military security personnel

- the Ka-band Dual Gridded Reflector developed by HPS for very stringent mass requirements

- the Q/V-band Feeder Link Top Deck Antenna as a component of future telecom satellites

- the 1.6-m antenna reflector for Ka- and Q/V-band applications – an innovation supported by DLR

- gold plated tungston meshes for large deployable antennas, developed in cooperation with companies and universities in the Bavarian „textile triangle“

- the HPS-development of serially manufactured electronic boxes based on CFRP.

Peter Rauhut, CFO and also co-owner of HPS finally presented the full picture of the business situation of the enterprise growing at high speed since its foundation 15 years ago. In particular, he outlined the enormously positive growth impulses generated by the successful MLI-production of the Portugese subsidiary.

Ernst Pfeiffer outlined the importance of combining a top-quality serial production in Portugal at prices unparalleled with continuous development of new products in Germany in order to win and keep the support of banks accompanying the company´s growth even at fast pace. He also stressed the fact that the obviously strong support by politics in Bavaria and Berlin serves as yet another important cornerstone of trust towards HPS in the financial sector. There is enough room for yet further growth through innovations that lead to serially manufactured products, as an example Pfeiffer hinted at a soon upcoming development of GTO-satellite antennas for the transmission of Galileo-data.

Impressed by the dynamics, the technology and the company culture at HPS the delegation agreed to arrange for successive meetings on yet more detailled subjects in the near future.

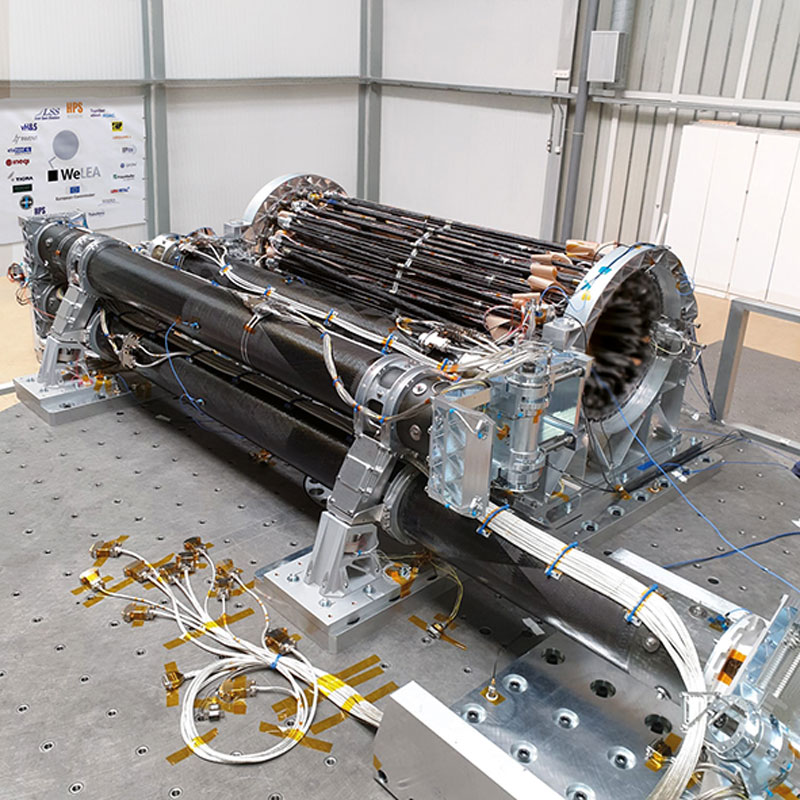

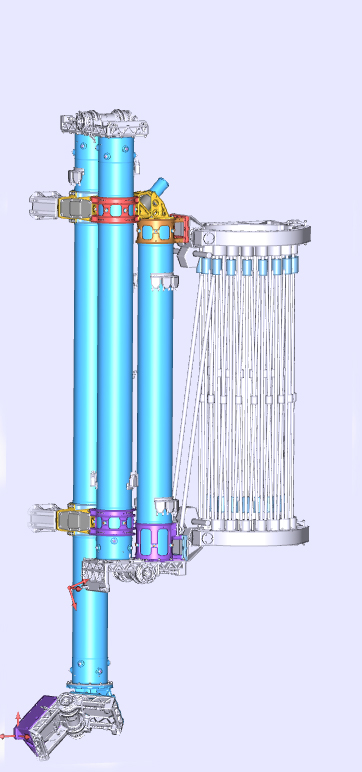

Test of LEA´s arm a full success

March 2021

Europe´s innovative deployable antenna technology takes the next hurdle

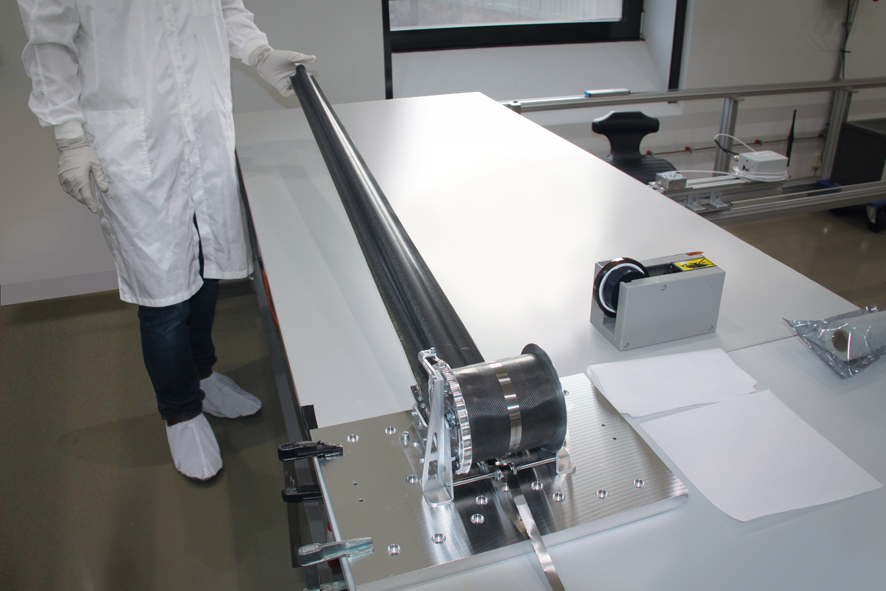

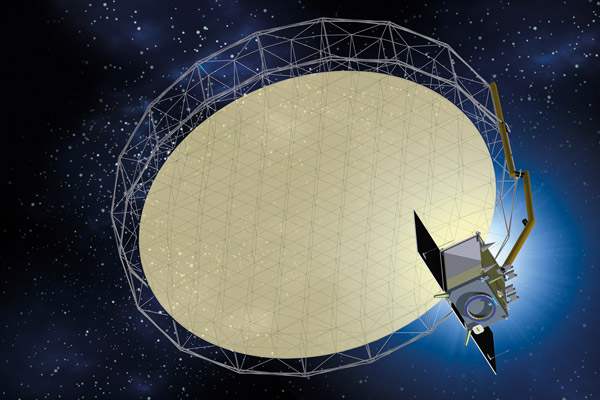

With the successful test of the Deployable Assembly Arm (DAA), which connects a Deployable Reflector Assembly (DRA) to the satellite, just completed at INEGI, the European LEA consortium led by HPS has cleared the next hurdle in the technical realization of Europe’s new antenna technology.

The 5m long DAA consists of 3 hinge mechanisms and 2 HDRMs (both by RUAG Space Germany), Release Mechanisms (by Arquimea, Spain), three CFRP tube segments (by INVENT, Germany), Metal Fittings (partly by HPS Romania), Deployment Control Electronics & EGSE (by von Hoerner & Sulger). Focus of the tests have been the verification of a) the functional full deployment (which takes in total 25 min.), b) a high pointing accuracy of the arm and c) the verification of the mathematical thermo-elastic models.

INEGI (Portugal) is the main partner for the arm deployment test and a good partner of HPS for over 13 years now. INEGI was responsible for the 0-g-simulation Test Stand and the Thermo-elastic Distortion Test Stand. Despite the pandemic and all restrictions the teams could manage this progress with highest motivation and closest possible contact between the INEGI/HPS team on-site in Porto and the HPS-engineers in Germany. HPS is responsible for the DAA and also for the implementation management of the whole LEA-activity. The total LEA-team encompasses 15 partners from 7 countries; the program started in the framework of H2020 in November 2017. The arm deployment test and the TED-test (thermo-elastic distortion) was one of the last tests of this H2020 activity.

The next step – starting still in March – is the environmental test (vibration and thermal vacuum) of the full LDR-Subsystem (Reflector, Arm and HDRM, all connected), which will be performed at INTA in Madrid, Spain.

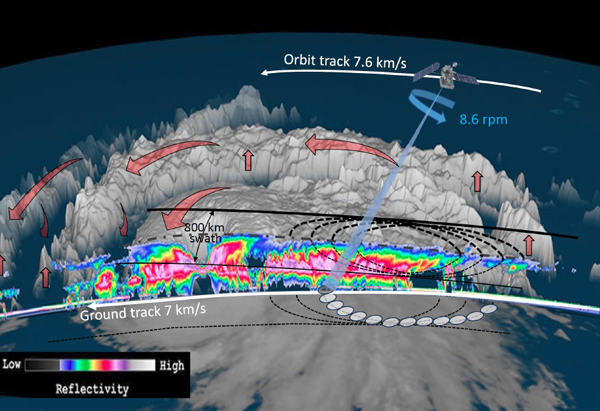

“LEA-X5” (5m reflector diameter, 5m arm length, X-band application for Earth Observation and Telecommunications) is meanwhile seen as one of the precursing technology developments for the current Copernicus CIMR Mission.

Manfred Krischke and Peter Müller-Brühl take over still available minority shares

March 2021

Renowned tech and space entrepreneurs join HPS Munich

It was sealed with a short signature ceremony on March 17, 2021: Manfred Krischke and Peter Müller-Brühl are now co-partners of the leading German space company HPS GmbH, Munich.

Last year, the specialist for technically sophisticated and innovative mechanical-, thermal-, and antenna-subsystems prevailed against all competition as the consortium leader of a group of fifteen space companies from seven countries, and with the order for the development and production of a self-deploying 8 meter arm- and reflector-subsystem for earth observation, the 100 Million Euro limit broken for a single project.

In addition, the company is, under the management of the main managing partner Dr. Ernst K. Pfeiffer, in a worldwide race to develop an automatic return system (so-called de-orbiting) for disused satellites and rocket parts; options for the self-deploying decelerating sail ADEO in various sizes are already being accepted from all over the world. And finally, HPS Munich, just like the subsidiary in Romania, is well positioned in conventional business with project orders from the areas of telecommunications, space exploration, earth observation and security, despite all the adversities of the corona situation. HPS remains in the possession of German space enthusiasts: in addition to the new investors and main shareholder CEO Pfeiffer, the HPS group of shareholders also includes a private investor and four senior employees. In addition, there is a small participation by another space SME.

“This mixture of ‘New Space’ and conventional ESA, DLR and EU business is a solid basis for long-term sustainable business success”, Krischke is certain: “At HPS, courageous innovative genius and many years of experience come together for what is feasible. That is the formula for success of HPS. “Peter Müller-Brühl sees great opportunities in the potential of HPS: “Similar to Clean-Energy, Clean-Green-Space will very soon also become a global socio-political demand in view of the tens of thousands of planned satellites space debris is already an important topic for many people. With the deorbiting solution from HPS, we will bring sustainability to the space industry”.

Last but not least, these prospects are reflected in the company’s value. HPS does not give exact figures, however, HPS CEO Pfeiffer notes: “We see it as a great honor that Messrs. Müller-Brühl and Krischke, as experienced space entrepreneurs, decided to engage themselves in HPS, especially because of the high potential for increased value recognize via the NewSapce or commercial space line from HPS that we – I am sure – will lift very quickly together with our new members of the ‘HPS family’.”

Indeed, Krischke and Müller-Brühl are highly experienced high-tech and space managers – Kayser Threde, RapidEye, Daimler, GreenCom Networks are just a few key words from their professional careers. What they have in common is the founding of Cloudeo AG as the largest independent platform for satellite-based geodata and applications. In addition, both are active as members of the supervisory board of Mynaric AG, the world’s leading technology provider for satellite-based telecommunications via laser, another “Shooting Star” in the German space sky.

European Premiere

March 2021

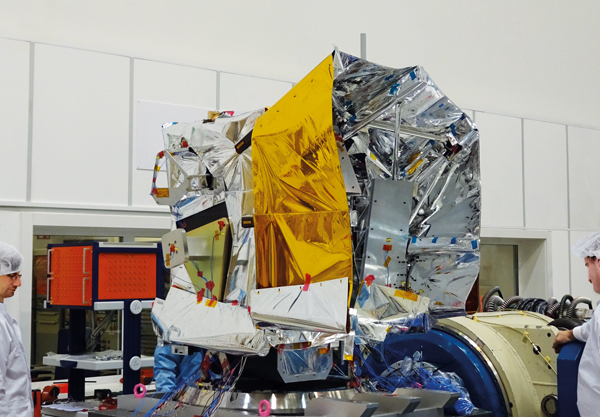

Arm and Reflector of LEA-X5 Successfully Mated to Form Complete Subsystem

Fifteen companies – mostly SMEs – from seven countries and one goal: a deployable 5-meter X-band-antenna as a preliminary development for the CIMR project, developed under the European H2020 program (2017-2021). For the first time ever, such a complete subsystem (HPS) has now been successfully assembled in Europe from the reflector- (LSS) and arm- (HPS) assemblies. Previously, the test deployment of the arm and reflector – each individually – had already been successfully passed.

LEA-X5-Subsystem is now at the premises of the consortium´s highly reliable test partner INTA in Spain, where vibration tests for the subsystem are on the agenda in the presence of the LSS- and HPS-teams. In a third round of testing, the subsystem will have to prove itself capable of withstanding the conditions of the thermal chamber.

The next complete subsystem-hardware in this context – the CIMR LDRS-EQM – will be assembled end 2023.

With the key technology behind LEA-X5, the continent is decisively expanding its independence from non-European sources.

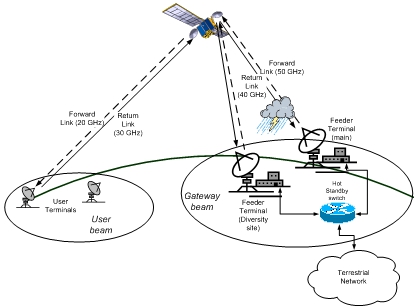

HPS being awarded the Q/V band antenna project FLANT

February 2012

The objective of the project is to develop a high-performance Q/V-band Earth deck antenna for broadband feeder link application. The baseline antenna will be designed and analyzed at RF, mechanical and thermal levels, supported by critical bread boarding when necessary. An Engineering Model of the selected antenna will be manufactured and tested.

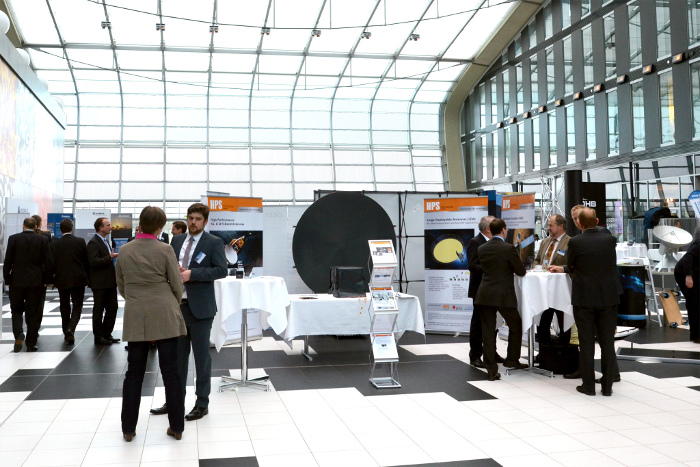

HPS at German Congress on Satellite Communications

March/April 2012

HPS was attendee, exhibitor and held speeches on the German national conference about satellite communications. The topics of the HPS speeches were:

- Q-V-Band applications

- Q-V-Band antenna structures

- High Tech and latest technology for Ka-band antennas and reflectors.

- The shown model is our full CFRP STANT antenna (environmentally tested and RF tested in Ka-/Q-/V-band).

More information on the congress can be found on the DLR homepage.

HPS at German Congress on Satellite Communications

March/April 2012

HPS was attendee, exhibitor and held speeches on the German national conference about satellite communications. The topics of the HPS speeches were:

- Q-V-Band applications

- Q-V-Band antenna structures

- High Tech and latest technology for Ka-band antennas and reflectors.

- The shown model is our full CFRP STANT antenna (environmentally tested and RF tested in Ka-/Q-/V-band).

More information on the congress can be found on the DLR homepage.

Successful PIM campaign at ESA-VSC High Power RF Laboratory

September 2012

In the frame of a German national project called HISST a comprehensive (research) PIM test campaign has successfully been conducted. Not only the verification of HPS reflector technology concerning PIM but also a comprehensive material and design research was essence and purpose of this campaign.

Key facts:

- frequencies in Ka-band

- PIM order: 7th, 9th, 11th and 13th were investigated

- material samples, breadboards and reflector models were tested (more than 60 tests overall)

- Mostly CFRP parts but also future space materials

- HPS PIM mitigation measures analysed.

Successful vibration and acoustic campaign of 1.6m Ka-band reflector

October 2012

The vibration and acoustic test campaign has been finished successfully. The reflector is a 1.6m side deployable Ka-band reflector featuring novel technologies and a full CFRP design. It is a collaborative development with Invent (manufacturing) and Technische Universität München (testing technologies and material science) as well as HPS being reflector subsystem responsible, project coordinator and being in charge of design and analyses.

Key tests among other test runs at IABG were:

- sine vibration qualification loads

- random vibration qualifications loads

- acoustic qualifaction loads.

Test to be performed:

- Thermal vacuum cycling.

Key facts of reflector:

- Ka-band

- 1.6m aperture

- GEO application (Tx/Rx)

- full CFRP

- ultra stiff (first eigenfrequency at approx. 130 Hz)

- reflector structural mass approx. 9 kg (even lower mass is possible)

- extremely low thermal-elastic distortions thanks to full CFRP design.

Münchner Weltraumschmiede HPS: Kleidung für Satelliten

December 2012

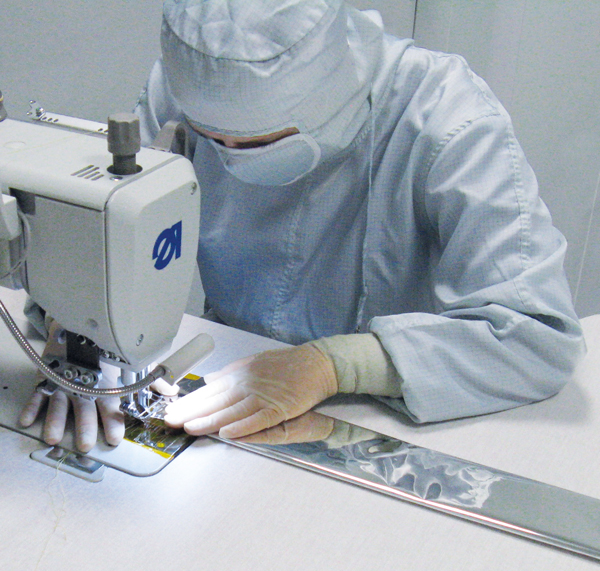

Im Weltraum ist es kalt – und heiß. Satelliten, die beispielsweise aus 36.000 Kilometern Höhe über der Erde ihre Fernsehprogramme abstrahlen, sind auf der Sonnenseite Temperaturen von plus 120 Grad ausgesetzt, während auf der anderen Seite die Kälte des Alls mit minus 170 Grad an ihnen nagt. Ausgeglichen wird diese Differenz durch eine maßgefertigte weltraumtaugliche „Daunenjacke“, den Thermalschutz (im Fachjargon: MLI, Multi-Layer-Insulation).

Allein etwa eintausend kommerzielle Satelliten im Wert von über dreihundert Milliarden Euro sorgen weltweit für Telefon-, TV- und Datenübertragung. Dazu kommt noch eine Vielzahl von wissenschaftlichen Satelliten, die in die Ferne spähen oder die Erde beobachten. Für ihre angemessene „Bekleidung“ und damit Funktionsfähigkeit sorgte in Europa bislang vornehmlich ein großer Hersteller aus Österreich, dessen Marktherrschaft seit neuestem die kleine Münchner Raumfahrtschmiede HPS mit deutlich niedrigeren Kosten bei zertifizierter gleicher Qualität attackiert. Das Rezept: Die Forschungs- und Entwicklungszentrale in Deutschland hat nach fünf Jahren Vorbereitung ihre Tochtergesellschaft in Porto zum Produktionsstandort qualifiziert und ausgebaut; Die Entwicklung der Schnittmuster, Nähverfahren und Halterungen wird durch Spezialisten hauptsächlich in Deutschland durchgeführt.

In den vergangenen Wochen wurden die letzten Maßanfertigungen des Thermalschutzes für das drei Meter hohe Weltraumteleskop „eROSITA“ des Max-Planck-Instituts für extraterrestrische Physik in Garching bei München angelegt: Insgesamt rund 80 unterschiedliche Kleidungsstücke mussten für die hochgenaue Struktur entwickelt werden. Das Teleskop wird ab 2014 an Bord des „Spektrum-Röntgen-Gamma“ – Satelliten erstmals den gesamten Himmel auf der Jagd nach „Dunkler Materie“ kartographieren. „Das eROSITA-MLI ist der bisherige Höhepunkt unserer erfolgreichen Entwicklung und Fertigung. Im Oktober haben wir zudem gerade eine Garderobe aus ca. 120 Teilen für das Landungsraumschiff der kommenden ESA-Mission zum Mars begonnen, und für rund ein halbes Dutzend weitere Satelliten-Thermoanzüge erwarten wir den Zuschlag. Daneben sehen wir unser Potential auch in unzähligen kleineren Aufträgen für Satelliten-Unterlieferanten, die vom Marktführer bisher aus unserer Beobachtung nicht optimal bedient werden. Unser Angebot bietet nicht nur den Kunden eine Alternative zum bestehenden ´Monopol´; es zeigt auch, welche Chancen in Europa für grenzüberschreitende Unternehmungen gerade im Hochtechnologie-Bereich Raumfahrt bestehen. Die derzeit zwölf Arbeitsplätze im krisengeschüttelten Portugal sind sicher, fünf bis zehn weitere kommen bald hinzu; in Deutschland werden wir parallel von 30 auf 50 Mitarbeiter wachsen“, so der HPS-Chef und Raumfahrtingenieur Dr. Ernst K. Pfeiffer. Kunden sind neben der europäischen Raumfahrtagentur ESA (Paris) und der deutschen Raumfahrtagentur DLR (Bonn) Unternehmen wie die OHB-Tochter Kayser-Threde (München), ThalesAleniaSpace Italia (Turin) und das Max-Planck Institut für extraterrestrische Physik (Garching).

Heinrich Hertz North Beam Antenna Reflector – H2KAR-PDR

May 2013

H2KAR reflector

The objective of the H2KAR activity is to produce, assemble, integrate, test and verify a full CFRP antenna reflector PFM for a German GEO orbit communication mission (Ka band). This reflector makes use of several innovative technologies being developed by HPS and its partners.

The aim of developing these technologies at HPS and partners is meeting future spaceborne antenna requirements. In order to obtain a space qualified product the final step is the demonstration of successful on-orbit operations, also known as in-orbit verification/ validation (IOV). This is the point where novel HPS antenna technologies meet the German mission called H2Sat because one of its missions purposes is bringing new technologies into orbit.

H2KAR phase B was launched in October 2012. Some preliminary key characteristics of the reflector are:

| Orbit | GEO |

| Type | Single offset side deployable |

| Frequency | Ka band |

| Aperture | Approx. 1.0m |

| Coverage area | Northern Germany, North Sea, Baltic Sea |

More information on the Heinrich Hertz Mission are found on the DLR website.

Alphasat launch with HPS MLI being aboard

July 2013

On July 25th the satellite Alphasat was successfully launched by an Ariane 5 launcher. This means, the first HPS and Portuguese multilayer thermal insulation (MLI) was also launched to space. The MLI being on orbit it is also a flight premiere for the whole HPS family. Currently, HPS is designing the MLI for the European Exomars mission.

HPS attending SSMET 2014 and EuCAP 2014

March/April 2014

HPS attends to the European Conference on Spacecraft Structures, Materials & Environmental Testing (SSMET) 2014 in Brunswick, Germany. Moreover, serveral publications are subject to oral presentations, i.e.:

- HIGH CONDUCTIVITY CFRP SANDWICH TECHNOLOGIES FOR PLATFORMS

- KUDGR – DUAL GRIDDED CARBON FIBER REINFORCED PLASTIC REFLECTOR

- NON-CONVENTIONAL CARBON NANOTUBE SKELETON REINFORCED COMPOSITES FOR SPACE APPLICATIONS

- SCALABLE – INNOVATIVE SCALABLE LARGE DEPLOYBLE ANTENNA REFLECTOR

- VANESSA – VALIDATION OF NUMERICAL ENGINEERING SIMULATIONS – STANDARDISATION ACTIONS

More information on the congress itself is found by following this link.

Visit our booth at EuCAP!

In addition, HPS attends and presents publications as well as contributes to the exhibition of the 8th European Conference on Antennas and Propagation (EuCAP 2014) in The Hauge, The Netherlands. The publications address the following topics:

- A Q/V-band Antenna for Feeder Link Applications

- An Ultra Rapid Deployable Antenna for on-the-field Satellite Communications

- In-orbit verification of novel reflector antenna technologies – the final step of a European-German development

- RF Design Challenges for a New DGR Concept

More information on the conference itself is found by following this link.

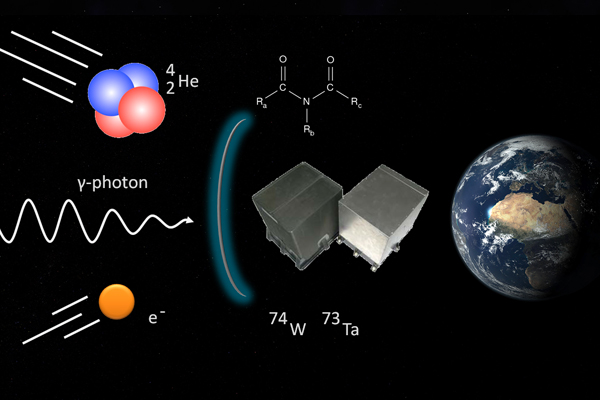

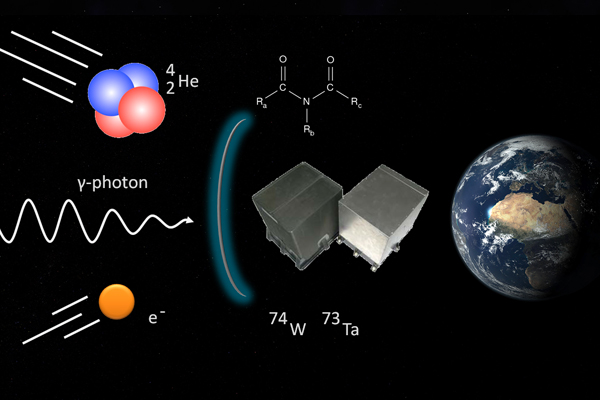

HPS awarded ESA contract for radiation protection study

August 2014

HPS has been awarded an ESA contract for the developement of a lightweight radiation proctection system for space applications.

The objective of the activity is to design, manufacture and test novel multi-layered shielding materials for protection of spacecraft electronics or other sensitive hardware. This technology shall offer improved shielding effectiveness compared to an equivalent

shielding mass of aluminium, for several mission scenarios.

Partners of HPS are Kayser-Threde and Fraunhofer Institut INT.

HPS workshop on radiation shielding development – REGISTER NOW!

September 2014

The European Space Agency has recently awarded HPS GmbH a GSTP-contract on “Evaluation of lighter and more efficient radiation protection for electronics and sensitive parts”.

At the beginning of this activity a workshop will be performed that represents a forum of bringing together between 15 and 30 experts from European industries and institutes working in the field of radiation

shielding for space applications. Contributions from non-space industries and institutes are highly appreciated as well.

The objectives of the workshop are to survey the state-of-the-art in shielding technology, review lessons learnt from previous projects and identify the future application areas and needs where more efficient shielding would be beneficial (e.g. for cost saving, mass saving, use of non radiation-hard parts etc.). Different types of shielding shall be addressed, including spot-shielding, add-on shielding, as well as shielding using enclosures.

30th & 31st October 2014, Munich

The preliminary programme will be published in due time after evaluation of the RSVPs and presentation contributions. The following overall schedule is planned.

Day 1 – 30th October 2014

On 30th October 2014, 11:30 registration and welcome including snacks. Opening sessions by the host and its partners will take place, starting at 13:00 (allowing for arrival at the same day). After that, the first presentations on radiation shielding shall be held.

Day 2 – 31st October 2014

The second day (October 31) starting at 09:00 is devoted to further presentations on radiation shielding, followed by a discussion board that summarises the key outcomes of the preceding presentations. The end of day 2 is estimated to be in the afternoon.

CEO of HPS meets Portuguese Ambassador

October 2014

On 11.10.2014 the Chief Executive Officer of HPS GmbH, Germany, Mr. Ernst K. Pfeiffer, met the Portuguese Ambassador of Germany, Mr. Luis de Almeida Sampaio. In the frame of the 50th annual convention of the German-Portuguese Association DPG, Mr. Sampaio and Mr. Pfeiffer exchanged experience made and future visions of space related activities. It was highly acknowledged that the German-Portuguese joint venture, HPS Lda., Porto, the subsidiary of HPS GmbH, Munich, develops very successfully and grows rapidly and that already in 2016 flight hardware made in Portugal will be launched to Mars on board the European mission ExoMars. HPS Portugal is producing here so called Multilayer Insulation for some scientist instruments and in addition for the complete Entry and Descent Module EDM.

Successful HPS workshop on radiation shielding development

November 2014

The European Space Agency has recently awarded HPS GmbH a GSTP-contract on “Evaluation of lighter and more efficient radiation protection for electronics and sensitive parts”. At the beginning of this activity a workshop took place bringing together European industries and institutes working in the field of radiation shielding for space applications.

The objectives of the workshop were to survey the state-of-the-art in shielding technology, review lessons learnt from previous projects and identify the future application areas and needs where more efficient shielding would be beneficial (e.g. for cost saving, mass saving, use of non radiation-hard parts etc.).

About 20 expertes attended and contributed to the workshop that was concluded very sucessfully. On this note, many thanks to the people shown below but also to the organisation assistants.

Attending entities were: Tesat-Spacecom, Max-Planck-Institute, OHB System AG, Fraunhofer INT, HPS GmbH, DLR, Technische Universität München (TUM), Thales Alenia Space Deutschland, Serenum a.s., ESA, STT-System Technik GmbH and HPS.

Key to Future Space-Com and Earth Observation: Large Deployable Antennas

Januar 2015

Under the auspices of the German ministry of economy and energy and DLR Germany had decided to entrust a team of SME-companies under the lead of RWTH-Aachen and several other highly renowned institutes with studies about mission profiles and potentials based on large deployable antenna (LDA)-applications, named SMERALDA (SME´s Radar and Large Deployable Antenna). HPS, the mid-sized antenna specialist and leading space-subsystem manufacturer, was responsible for the central LDA-part of the project that provided a respective concept for a small-scale-mission using a 5-meter LDA.

The study was successfully finished mid December 2014 and presented to a large audience at the German Space Agency in Bonn including to one of DLR’s directors Mr. Christoph Hohage.

Satellite Communications – Strategic Technology behind Germany´s Economy and Growth

April 2015

Practically no other space-technology provides so much impact on the future development of competitive knowledge- and information-societies like satellite communications. That is why the German ministry of economy and energy and DLR invited the leading companies in this field to the annual satcom-conference from March 25th to 26th in Bonn.

Prominently present among large system integrators (LSI) and small product suppliers (SME): HPS, the mid-sized antenna specialist and leading space-subsystem manufacturer. The Munich based R&D-division of HPS has welcome professionals at its attractive display centering around the company´s latest developments in the field of Q/V-band antennas, multilayer insulation (MLI) and large deployable antennas (LDA) and offered lectures about Q/V-band technologies at HPS as well as on its Ka-band antenna of Heinrich Hertz satellite.

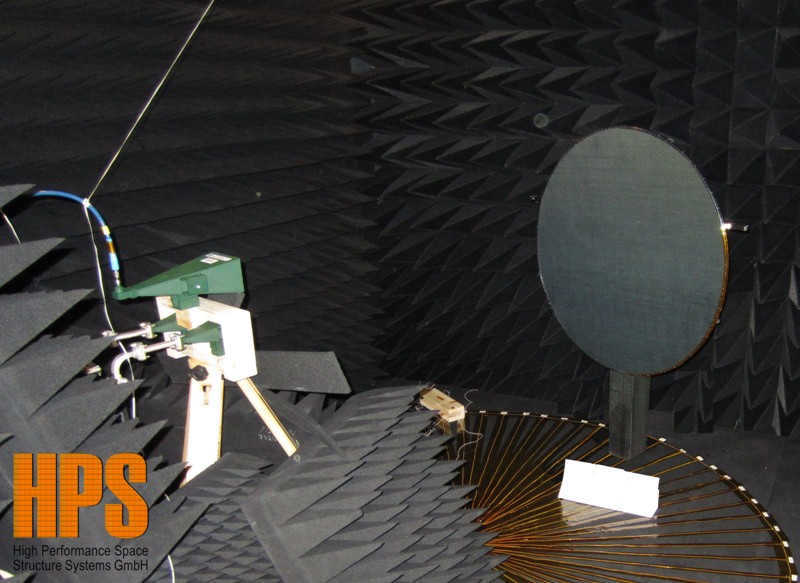

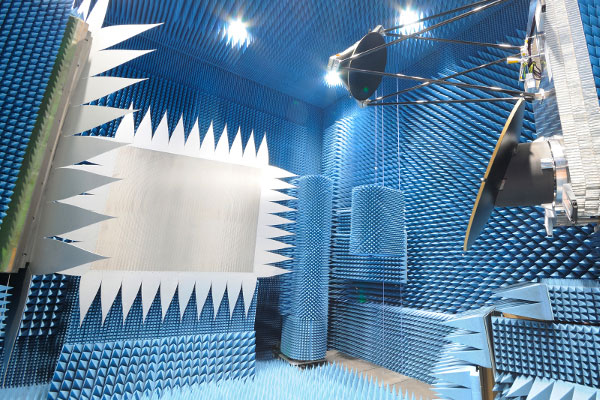

Q/V-Band Feeder Link Antenna Successfully Tested

Mai 2015

During May 2015 a large top deck feeder link antenna (Gregorian configuration, main reflector diameter: 1200 mm, sub-reflector diameter: 700 mm) working in Q/V-Band (Tx: 37.5 – 40.5 GHz, Rx: 47.2 – 50.2 GHz) has been successfully tested in the brand new RF Compact Range of the University of Applied Sciences in Munich.

HPS has developed this dual reflector antenna under contract to ESA since 2012. It was designed for European coverage, 8 gateways for nominal operations and 2 gateways for diversity sites. The reflector design is based on HPS’s Q/V-Band technology initiated in 2003 and flying on the German satellite Heinrich Hertz. The RF test has been performed under the lead of Prof. Fasold, a world wide acknowledged Antenna test expert.

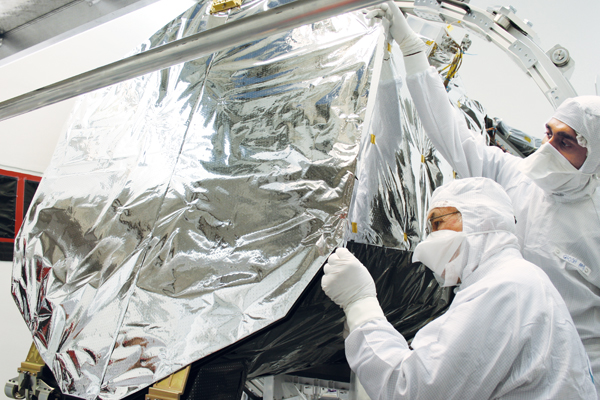

Integration of Multilayer Insulation for Flight onto Mars Finalized

July 2015

In January 2016, ESA launches the space mission ExoMars on its way to Mars. Arriving 9 months later in the Mars Orbit, the “Entry, Descent and Landing Module” (EDM) will separate from the mother ship and will land on the surface of Mars.

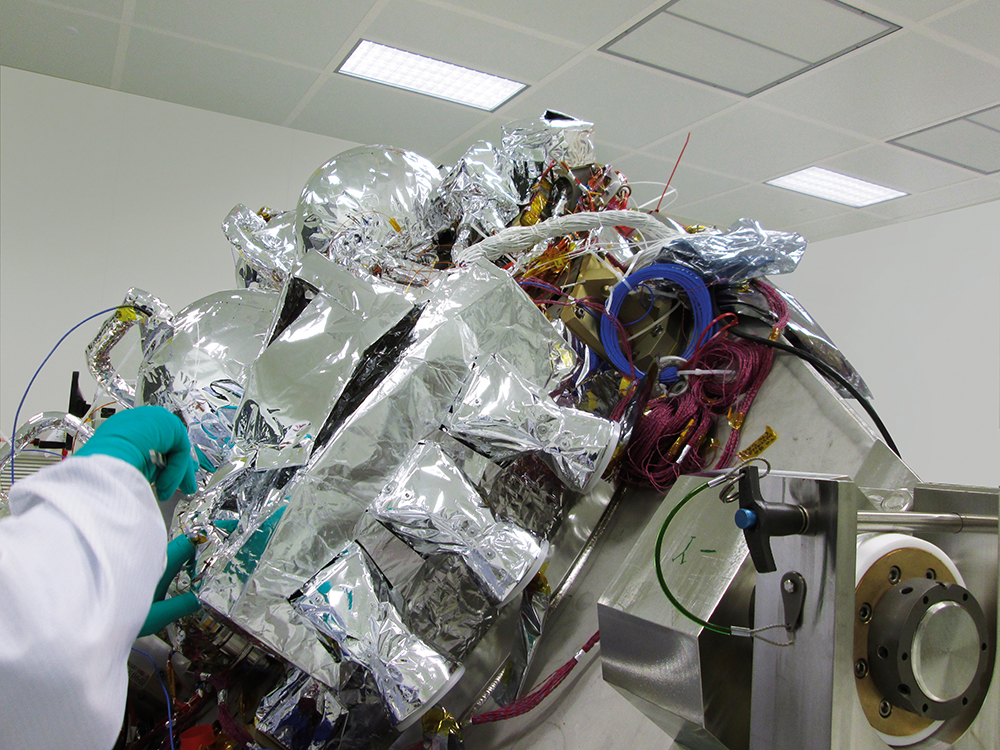

HPS Group received the contract for the complete Multilayer Insulation for the EDM-Lander in 2012. All internal and external blankets, ranging from tank-MLI, high temperature thruster MLI, standard tube MLI up to TPS-attached MLI, have been developed and manufactured by HPS Portugal until beginning 2015.

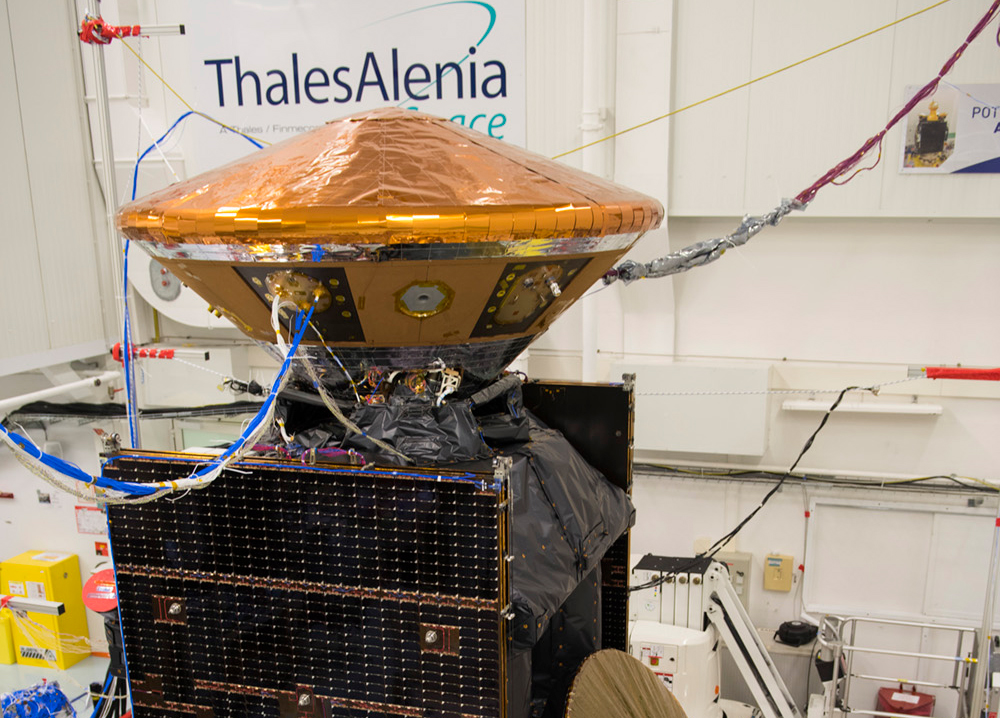

In plenty different integration campaigns during day and night, on site of the Customer ThalesAleniaSpace, Italy, HPS successfully attached more than 150 sheets directly on the flight hardware.

In April 2015 the whole spacecraft has been vibration tested under control of ESA.

And now, in July, HPS finalized its service with the last MLI AIT activities.

All HPS staff is proud to fly to Mars soon and thanks its Customers TAS-I and ESA for their trust in our capabilities.

For Further information on the ExoMars Mission, please click here: http://exploration.esa.int/mars/46124-mission-overview/

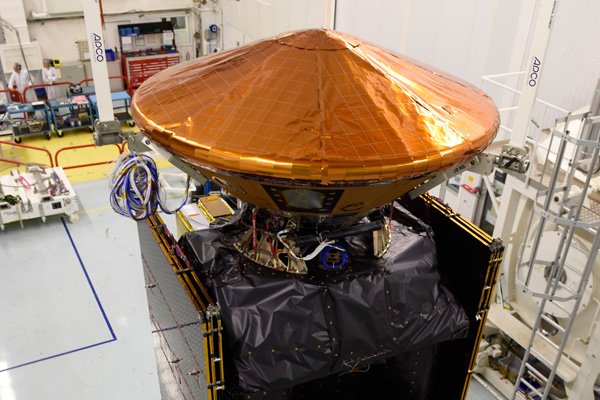

Ready for Mission to Mars: ExoMars Orbiter and Lander Shiaparelli Shipping to Launch Site

December 2015

Critical Thermal Protection made by Europe´s MLI-expert HPS in Portugal and Germany

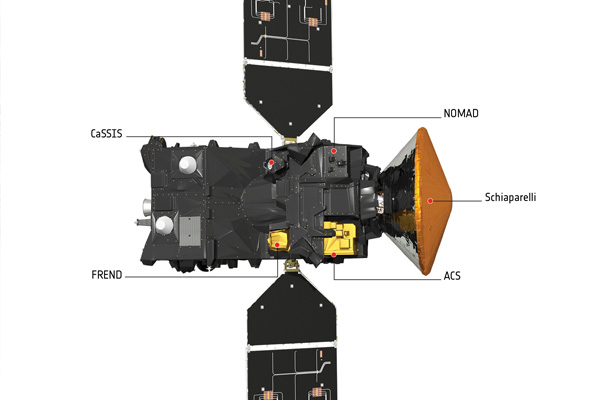

Scientists, media and other VIP´s from Europe´s space sector took the last chance on November 25th in Cannes to have a look at ESA´s latest exploration technology before it lands on Mars in October, 2016: Schiaparelli – an entry, descent and landing demonstrator module – is a technology-testing vehicle carried by the ExoMars Trace Gas Orbiter to demonstrate the capability of European industry to perform a controlled landing on the surface of Mars. The preparation for this mission enhances Europe’s expertise and enables the testing of key technologies which could be used in subsequent missions to Mars.

Although designed to demonstrate entry, descent and landing technologies, Schiaparelli offers a science package that will operate on the surface of Mars for a short duration after landing, planned to last approximately 2-4 sols (martian days).

Schiaparelli will be protected during its decend to Mars at a speed of 21,000 km/h as well as during its operations on the surface against all thermal impacts by a multilayer insulation designed, developed and manufactured by the Portugese space company HPS Lda.

„Thermal protection is one of the critical components that decide about success or failure of any space mission. However, with Schiaparelli it opens yet another dimension of human space exploration, since this spacecraft has the task to verify technologies for the generations of unmanned and finally human missions to land on Mars in future,“ said Ernst K. Pfeiffer, CEO of HPS. „In addition, my teams in Germany and Portugal have developed also the thermal protection for this mission´s scientific instruments CASSIS and NOMAD. All HPS employees in Germany and Portugal are extremely proud to serve as Europe´s selected thermal protection specialists in space, to have soon more than 10kg hardware on Martian surface and to play with this a vital part in man´s historic pathfinding mission to other planets.“

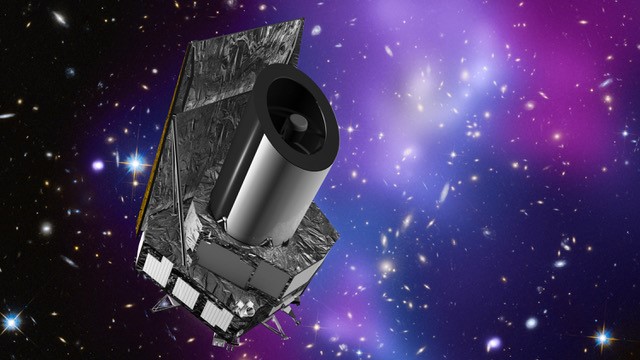

EUCLID-Assignment to HPS

December 2015

Antenna Reflector Assembly For Mankind´s Mission to See Whether Nothing is As It Seems

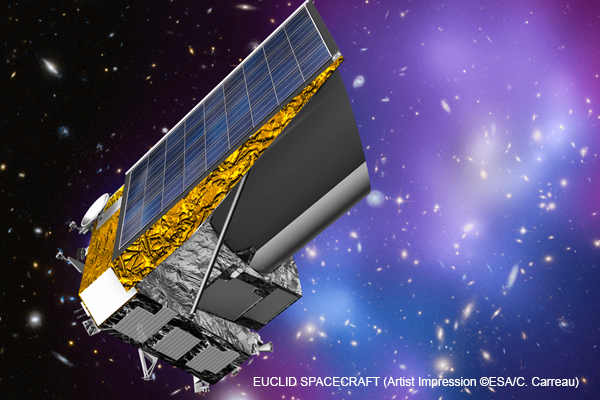

When in the first quarter of the year 2020 a Soyuz launcher lifts off heading for space from the European spaceport in French Guiana it will carry a very precious payload: EUCLID, the satellite on the hunt for dark energy which is supposed to be the force behind the acceleration of the universe´s expansion. An invisible force, nevertheless dominating the universe to the extent of about 70 percent – as it seems, while matter we can see makes up for only about five percent of everything that we want to know.

Thales Alenia Space has been selected as ESA´s prime contractor for the spececraft, while Airbus Defence and Space provides the payload module. Due to the outstanding characteristics of high performance structures made by HPS in terms of RF-reflectivity, minimized mass as well as thermo-elastic distortions HPS was selected by TAS (Spain) on December 4th to provide the high gain antenna reflector structure, from which all high resolution pictures of that mission will be transmitted to Earth. The engineering center of the German space-SME in Munich will design, develop and test the product, will overlook the production of structures at INVENT GmbH, Braunschweig, of the multilayer-insulation (MLI) at its specialized subsidiary HPS lda. in Portugal, and of metal parts at SERENUM from the new ESA member-state Czech Republic.

Based on robust and intelligent technologies EUCLID will be stationed for six years at the Lagrange Point L2, 1,500,000 kilometers away from earth, on a mission to make us see beyond the seemingly.

Taking the Next Step in ESA´s Clean Space Initiative

March 2016

ESA-Prime HPS with SME-Consortium Ready to Build New Generation De-Orbiting Subsystem

Hardly any messages have dominated the space community´s discussions in the past two years as perseverently as these two:

- the debris from past satellite missions forms a growing threat to future endeavors in space

- the number of satellites expected to form future constellations especially on LEO is exploding since new players are discovering space as their domain

- which again multiplies the problem of future debris.

So, on the one hand enormous growth of the satellite business is to be foreseen, on the other hand this business needs better rules in order to be sustainable. „Clean Space“ is ESA´s answer in general and the quest for a new, fully ecological de-orbiting sailsystem in particular.

While currently satellite manufacturers are already facing problems to comply with the 25-years-deorbiting „guideline“ without minimising the effectiveness and increasing the cost of their missions, ESA now aims to make this period as a strict requirement leaving neither ecological nor economical footprints.

Capitalizing on previous research and development in this area like the precursor project ADEO, led by the subsystem prime HPS with its consortium of DLR-institutes in Bremen and Braunschweig and the SMEs Etamax and HTS, ESA now announced its expectations for a full fledged demonstrator ready to fly by 2018 with a deorbiting time of lower than 5 years. The new project will be ignited this year and ESA´s subsystem prime HPS is expected to take this next step towards the final breakthrough in deorbiting technology, too, because:

- the current HPS precursor project ADEO, featuring a 5m x 5m deployable boom and sail subsystem weighing just 20kg, has been successfully tested on breadboard level in February 2016 and will reach design maturity for an Engineering Model manufacturing and assembly through a CDR in these days in March.

- ADEO will then already fulfill the requirements of providing sail and boom materials able to withstand the very severe Atomic Oxygen (AtOx) and Ultra Violet (UV) environment, offering scalability down to 100-kilo-satellites down from the current reference case of spacecrafts at 1-1.5 tons of weight, and of providing reliable deployment technology tested under ambient conditions and in a vaccum chamber in mid 2016.

HPS as ESA subsystem prime is aiming at the follow-on project also with its proven partners.

In parallel and as leading specialist on deployable structures and antennas, HPS Germany acts as prime contractor for Large Deployable Antennas (LDA) in cooperation with the German SME LSS, while the HPS subsidiary in Portugal is working on a deployable highprecision mast system (10-20m) for instruments weighing 100-250 kg on science missions.

The Countdown is on: Exomars on its Way through Deep Space

March 2016

To reach and land on Mars in 5,296 hours

Guarded by its Multilayer Insulation made by HPS Portugal the European landing demonstrator Schiaparelli will reach and enter the hostile Martian atmosphere at a speed of 21,000 km/h by October 19th this year, after 269 days or 5,296 hours of flight through the galaxy after a perfect launch on March 14th.

Large Deployable Reflectors: Europe takes another step towards non-dependence in space technology

April 2016

Prime HPS selected to lead network of space-SME to success

ESA has now awarded the contract for the development of „Mesh and associated carrying net for Deployable Reflector” (MESNET) to HPS. Kick-off for the project is scheduled May, 2nd, 2016.

Large deployable antennas and their respective reflectors are a critical asset in design and production of satellites for radar- and telecommunications missions like ESA’s BIOMASS and INMARSAT’s Alphasat. Until today, this technology is not available “as flight-verified” in Europe and still needs to be procured from American and Asian sources. But, Europe wants to play a role in that growing market of radar-oberservation and telecommunications satellites.

ESA has entrusted the functions of the subsystem prime to HPS Munich, while its Portugese subsidiary HPS lda, Porto, will be responsible for the assembly procedure and the actual assembly at a very high level of technology readiness (TRL).

In the context of the precursor study „SCALABE“ – to be concluded in summer 2016 – HPS also acts as prime contractor for the development of a 5-meter-demonstrator of a double panthograph deployable ring, which is being designed and built by HPS´Munich based collaborator LSS. Breadboarding of critical elements has already been performed by HPS in 2014/2015 and a mesh demonstrator has already been delivered by HPS for integration.

When in 2018 HPS will deliver the results of the MESNET-study – a vital element of ESA´s ARTES 5.1 technology program – the combination of both developments can result in a subsequent qualification model and finally in a flight model that could be ready as early as 2019/2010.

HPS-CEO Dr. Ernst Pfeiffer is confident, that Europe´s next step towards non-dependence in one of the most critical space fields will soon be taken: “The procedure to combine the capacities and outstanding abilities of specialized space SME under the prime and leadership of HPS is meanwhile a proven approach. We are certain that by 2020 ESA will be in the position to replace yet another position on the list of badly needed capabilities by `best of space`- technology made in Europe.“

European HPS-Group Growing

May 2016

With new subsidiary in Romania now present in three countries

Even before the end of a strong year 2015 the top-management at the headquarters of the European HPS-group in Munich, Germany, had set the course towards expansion; it took just a few months until on May 3rd, 2016, the Romanian subsidiary „High Performance Structures Inovatie si Dezvoltare S.R.L. (HPS – RO)“ opened its gates as the third member of the HPS-Group. Owner of HPS-RO is the German High Performance Space Structure Systems GmbH (HPS-D), whose main shareholder, Dr. Ernst K. Pfeiffer, is also the founder and CEO of all company members of the group. In addition, further managers, employees as well as strategic investors hold shares in the German and Portugese HPS companies.

HPS-RO will cover the need for additional capacities of the group in the fields of engineering, development, secondary and tertiary structures, as well as MGSE (mechanical ground support equipment). Suppliers and partners in Romania are highly renowned companies, institutes, and universities specialized on mechanical precision manufacturing, welding, material- and structure characterization, process verification and testing. Final assembly will be carried out by HPS in Bukarest.

HPS-RO has taken residence in „Sector 2“; the place is close to the local subway, just three kilometers from the city center, 20 kilometers from the international airport Otopeni and almost directly adjacent to the large traffic arteria of the country that connect Romania tightly with Western Europs webs of logistics.

The Romanian company starts with a core staff of 5-8 project managers, engineers, technicians and other specialists, headed by Astrid Draguleanu, herself an engineer. This move takes the HPS group beyond the threshold of 60 highly motivated members of the „Team to Trust“, as the company slogan states. The Romanian core team is planned to double in numbers as fast as possible. This will help to surpass the target mark of 100 employees of the HPS group in Europe even quicker than it was announced for 2020 by CEO Ernst Pfeiffer just two years ago.

The reason for the steady and strong growth the revenues of which are – as a company principle – immediately reinvested in new technologies as well as in lateral growth and, accordingly, in jobs – is that the company has successfully established its position as one of the very few medium-sized subsystem specialists for the European – and will be so soon – on non-European space markets. At an early stage the entrepreneur had realized that it will be just a matter of time that commercial structures will rule the space business, too. That, in consequence, means that it will take larger midsized companies to help the large system integrators reduce their vertical manufacturing integration by delivering complete subsystems and assembles in order to give room for a stable and manageable chain of value adding from the smallest part to the final product.

„Space is a growing business“ says Pfeiffer, „it develops along the lines of increasing commercial demand on markets like satellite based television, communications, and navigation, while at the same time there is a stable need for high end space technologies in service of science as well as of governments securing borders and observing earth, oceans and climate change. It is just like in the automotive branch: The dominating labels realize their added value to a great extent on the basis of the quality of cost effective subsystems. The stronger the growth of the mark, the better the chances for the best on the next level, who are also big enough to manage the coordination of many suppliers of single parts.“

Numerous discussions with politicians and managers from countries that had in the beginning been opted for at HPS headquarters have finally led to the decision in favor of Romania: “Romania is among the countries that on the one hand have the largest need to catch up with Western economic standards of living, on the other hand Romania indeed has outstanding universities and top-level capacities of engineering and quality standards. In addition, the country has a long tradition in aeronautics and aerospace: The first jet aircraft wasdesigned and constructed by the Romanian engineer Henri Marie Coandă as early as 1910. Progress in Romania will therefore take place in big leaps, not in small steps. All it takes is a series of little pushs, and one is now coming from us.“ so Pfeiffer on the outlooks for the third member of the European HPS group.

New Space – der europäische Weg – ein Weg durch und für KMU

June 2016

Interview HPS-SpaceNews mit Dr. Ernst Pfeiffer, CEO von HPS und Sprecher der deutschen Raumfahrt-KMU im AKRK

Space-News:

In den letzten Wochen und Monaten haben Sie als Sprecher der deutschen Raumfahrt-KMU einen Marathon der Veranstaltungen in Vorbereitung der ESA-Ministerratskonferenz absolviert. Kam diese plötzliche Berücksichtigung der Raumfahrt-KMU durch die Institutionen für Sie überraschend?

Pfeiffer:

Keineswegs. Zum einen haben wir in den vergangenen Jahren sehr stark drauf hingearbeitet, dass unser AKRK-Zusammenschluss der rund 40 von insgesamt 90 Raumfahrt-KMU mit ca. 1500 von insgesamt 2500 Beschäftigten in Deutschland endlich als einziger unabhängiger Ansprechpartner des Mittelstandes zur Kenntnis genommen wird. Und sicher hat auch unsere kumulierte Darstellung von Kompetenz, Wirtschafts- und Innovationskraft in der kürzlich vorgestellten Website „Best-of-Space.de“ dazu beigetragen. Wir sind in der Tat auf Augenhöhe mit den Großen der Branche von ESA und deutschem Wirtschaftsministerium berücksichtigt worden. Das galt zwar schon zum High Level Forum der ESA im Juni letzten Jahres, startete aber dieses Jahr intensiv mit einem Vortrag über das Technologieprogramm vor den ESA-Delegierten am 9. Mai, ging über ein Top Level Gespräch über die ESA Strategie zwischen ca. 10 CEOs der europäischen Raumfahrtfirmen und ESA-Generaldirektor Herrn Wörner mit allen seinen Direktoratschefs am 12. Mai, weiter zur Panelveranstaltung „New Space“ am 2. Juni auf den Space Days der ILA in Berlin und schließlich zum diesjährigen High Level Forum der ESA am 20. Juni auf dem ich im Panel über „Next Steps for ESA“ eingeladen bin.

Space-News:

Alle reden von „new space“ ….

Pfeiffer:

Genau, alle reden über „new space“ – und meinen in Ermangelung eines europäischen Weges den amerikanischen, der da lautet: „machen, was finanzkräftige Quellen haben wollen“ und „mit privatem Risiko finanzieren, und wenn es schief geht werde ich auch nicht arm woran man selber glaubt“

„Masse über Klasse stellen und dabei Qualitätsverluste in Kauf nehmen, solange sie sich zumindest kurzfristig rechnen“.

Space-News:

Ist das auch der europäische Weg?

Pfeiffer:

Niemand in Europa wird das unterschreiben. Zum einen, weil es diese finanzkräftigen Unternehmen in D und EU nicht gibt, ebenso wenig wie die Risikofinanzierer und schon gar nicht die Mentalität, nicht nachhaltiges Billiges zu bauen, dabei Qualität zu opfern und Folgekosten (Schrott etc) für kommende Generationen ohne Ansicht der Dimension in Kauf zu nehmen.

Abgesehen davon, ist es ein gewaltiges Risiko, sich darauf zu verlassen, dass schon genügend reiche Unternehmen aus den USA auf Ideen kommen, wie sie denn durchgehend die Raumfahrtindustrie in Europa beschäftigt halten können.

Space-News:

New Space in diesem amerikanischen Sinne ist also weder europäisch, noch ist es geeignet, gerade KMU eine Perspektive zu geben?

Pfeiffer:

New Space europäischer Machart wäre das Ergebnis auch europäischen Vorgehens und Denkens. Und da haben wir eine Menge aufzuweisen. Wir machen nicht einfach mal eben so etwas, weil es vielleicht hier oder da kurzfristig Gewinn bringt – wir machen überhaupt nichts nur nach dem reinen Prinzip kurzfristigen ökonomischen Gewinns. Wir machen die Dinge in Europa so wie wir sie machen, weil für uns hier die Dinge immer einen viel tieferen Sinn und Nachhaltigkeit, als kurzfristig in Dollar messbar ergeben müssen. Ziel in Europa war es bisher, nicht nur eine Handvoll reicher Unternehmen noch reicher zu machen, sondern möglichst viele Unternehmen nachhaltig und langfristig zum Wohle einer unabhängigen, ausgeglichenen Gesellschaft zu erhalten. Derzeit besteht

Gefahr, dass dieses Gleichgewicht und die Unabhängigkeit in Europa kippt.

Space-News:

Wie drückt sich das aus?

Pfeiffer:

Lassen Sie mich ein Bild bemühen. Nach eben beschriebener amerikanischer Mentalität soll ein Produkt hinreichend funktionieren, nur Schäden für den unmittelbaren Nutzer müssen ausgeschlossen bleiben. Auch wir können uns sicher nicht alle der Faszination eines mächtigen V8 und dem Reiz vergleichsweise unendlichen Sitz- und Reisekomforts eines typischen US-Autos entziehen. Im Gegensatz zum Amerikaner nehmen wir es dann aber schon übel, wenn zugunsten eines schnelleren Verkauf garantierenden Preises dann unterwegs mal ein Knopf hier abfällt oder ein Schalter da nicht funktioniert. Und erst recht unakzeptabel ist für uns die Vorstellung von ressourcenvernichtenden Trinksitten und materialverschwendendem Design, was alles dann nur nachfolgenden Generationen Probleme macht. In Europa denken wir anders; Nachhaltigkeit hat für uns zwingend etwas mit Qualität zu tun. Darin sind wir gut, und darin sind wir besser als alle anderen – USA, Asien, Russland.

Space-News:

Was folgt daraus für „new space“ made in Europe?

Pfeiffer:

Wenn das so ist, sollten wir das auch zur Grundlage unseres „European way of new space“ machen. Nicht warten, bis irgendwer von irgendwo irgendeinen kommerziellen Auftrag platziert, sondern die Landschaft solcher Aufträge samt Staat, Auftraggebern, Programmen und Auftragnehmern selbst vorzeichnen.

Wenn wir als KMU politik- und öffentlichkeitswirksam dieses Feld der systematischen Suche nach vernünftigen, nachhaltigen und politisch wie wirtschaftlich höchst wünschenswerten „new space – Projekten made in Europe“ besetzen, besetzen wir damit gleich das ganze Feld „new space“ selbst und jegliche Diskussion darum. Wir stellen solide Weichen, statt blind Trittbrett zu fahren!

Space-News:

Kann das wirklich in Anbetracht der „unendlichen Möglichkeiten“ jenseits des Atlantiks funktionieren?

Pfeiffer:

Sicher kann es das, und ich bin darüber hinaus sicher, dass es seine Wirkung auf den „American way of new space“ auch nicht verfehlen wird. Nehmen Sie wieder das Bild vom Auto. Wie kommt es wohl, dass amerikanische wie auch japanische Hersteller in den letzten rund zwanzig Jahren vermehrt dazu übergehen, europäisches Design, und europäische Technik und Europäisches Umweltbewußtsein als Maßstab mitzunutzen? Das Bessere ist des Guten Feind, das wird auch bei „new space“ auf lange Sicht nicht anders sein.

Space-News:

Ist das Ihre Hauptbotschaft auf dem Marathon zur Ministerratskonferenz?

Pfeiffer:

Das und der dringende Hinweis, dass wir beim Hype um „new space“ unseren „old space“ nicht vergessen sollten, sprich: weiterhin Investition in Höchst-Technologie. Gerade wir Deutschen sind ja oftmals so eifrig dabei, neue Dinge – besonders, wenn sie aus den USA kommen – über das Bestehende zu stellen. Davor kann ich nur warnen. Bei aller Begeisterung für Neues – die liegt ja auch irgendwo in der menschlichen Natur – das zu vernachlässigen, was uns in der Raumfahrt groß gemacht hat, endet für uns im Desaster, in einer verlorenen Unabhängigkeit Deutschlands. Um abschließend noch mal den Autofahrer-Blick einzunehmen: Wenn wir mit unausgegorener Taktik, mangelnder Schnelligkeit und unzureichender (Finanz-) Kraft auf die linke Spur wechseln, um einer Chimäre nachzujagen, müssen wir uns nicht wundern, wenn uns traditionelle, staatsgetriebene Old-Space-Länder Europas und Asiens auf der Pannenspur technologisch überholen. Als Raumfahrt-KMU werden wir jedenfalls schön weiter hochinnovativ die technologische Mitte besetzen und von dort aus versuchen, flexibel mit neuen, kreativen Ideen von Anwender-KMU den „European Way of New Space“ zu leben.

Eine zweite Botschaft an die Ministerratskonferenz wäre noch: Nutzt die aktuelle Begeisterung für Raumfahrt in der Gesellschaft für Inspiration, europäischen Zusammenhalt, globale Zusammenarbeit und damit Friedenssicherung.

Gastbeitrag von „Best of Space“

October 2016

ESA-Ministerratskonferenz 2016: Gruppenbild vor neuem Hintergrund

Wenn sich am 3. Dezember des Jahres in Luzern nach Abschluss der Ministerratskonferenz die für Raumfahrt politisch Verantwortlichen der Mitgliedsländer der europäischen Raumfahrtagentur ESA zum abschließenden Gruppenbild versammeln, beginnt der mediale Marathon in den Ländern, die dort gefassten Beschlüsse als Verhandlungserfolge zu verkaufen.

Im Vordergrund werden dabei voraussichtlich, wie schon seit langem üblich, die großen Programme stehen: Wissenschaftsmissionen, Trägerraketen, Raumstationen – Themen eben, die sich der Mehrheit der Leser und Zuschauer, der Wähler, besonders gut nahebringen lassen.

Dabei geht es zwangsläufig auch um viel Geld – Geld, welches die Steuerzahler aufbringen müssen. Die staatliche Komplettfinanzierung aller Raumfahrtaktivitäten war in der langen Serie vorangegangener ESA-Ministerratskonferenzen, die alle zwei bis vier Jahre stattfinden, ein eherner Grundsatz und selbstverständliche Geschäftsgrundlage: Ohne Steuergelder keine Raumfahrt.

Doch seit kurzem könnten sich in der Raumfahrt neue, zusätzliche Geschäftsmodelle ergeben. Das Stichwort lautet: New Space. Im Kern bedeutet es, dass immer mehr von vornherein kommerziell ausgelegte Raumfahrtaktivitäten entstehen, weil private Investoren den Weltraum als Wirtschaftsraum entdecken. Ob mit Erdbeobachtungssatelliten, mit robotischen oder astronautischen Systemen, ob Spacemining, Megakonstellationen für Telekommunikation und Internet oder kommerzielle Deep Space Missionen – der Phantasie sind auch im New Space keine Grenzen gesetzt. Für die stets von Geldsorgen geplagte staatliche Raumfahrt müsste New Space daher eine hochwillkommene Entwicklung sein. Allerdings gelten bei New Space grundlegend andere Bedingungen, unter denen Raumfahrt erst zu einem wirtschaftlich einsatzfähigen Instrument wird:

- Serienfertigung tritt an die Stelle des Baus von Unikaten

- Statt langwieriger Entwicklung neuer Technologie mit bis zum Einsatz dann zwangsläufig veralteter Software bestimmt die neueste verfügbare Software Design, Funktion und Steuerung neuer Raumfahrt-Geräte

- Die Bedingung gleichermaßen terrestrischer wie raumfahrttechnischer Anwendbarkeit neuer Technologien steigert deren Effizienz auf ein auch im kommerziellen Kontext vertretbares finanzielles Niveau.

PARALLEL zu den wichtigen, teils regulierten nationalen oder kontinentalen Staatsmärkten (manch einer spricht von „Old Space“) entsteht so ein mehr oder weniger freier globaler Markt von Angebot und Nachfrage. Damit ist New Space eine Entwicklung, die auch der staatlich finanzierten Raumfahrt indirekt Entlastung durch Steuereinnahmen aus kommerziellen Märkten und technischen Synergieeffekten schaffen wird. Neue Handlungsspielräume für den Staat, für die Raumfahrtindustrie und clevere Unternehmer auf der Anwenderseite eröffnen sich neue Perspektiven.

Im Bereich der Raumfahrtindustrie betrifft dies in erster Näherung vor allem jene Unternehmen, die an die grundlegenden Bedingungen von New Space bereits heute am besten angepasst sind: Die Zulieferer, Softwarespezialisten und Komponentenhersteller der großen Hauptauftragnehmer nationaler und supranationaler Staatsprogramme – den Mittelstand der Raumfahrtindustrie.

Im Bereich der ESA-Programme erhalten sie die Möglichkeit einer Förderung ihrer Kompetenzen durch die speziellen Technologieprogramme „ARTES3/4/5/20“ und „GSTP“. Wie allerdings die Akronyme selbst – und ihr relativ komplizierter administrativer und technischer Hintergrund erst recht – schon nahelegen, handelt es sich leider eben nicht um jene Projekte, die sich als populäre Fußnote zum Gruppenbild der ESA-Minister eignen. Daher besteht derzeit eine gewisse Besorgnis, dass gerade diese Projekte – wie möglicherweise auch entsprechende Teile des nationalen Programms – bei der kommenden Ratstagung der ESA angesichts immenser Kosten(-steigerungen) konventioneller Großprojekte in den Hintergrund geraten. Und das, obwohl nur in der Ertüchtigung der Industrie und insbesondere des flexiblen Mittelstandes für den neuen kommerziellen Raumfahrtmarkt die großen Chancen liegen, langfristig Steuereinnahmen aus kommerziellem Geschäft zu erwirken und damit auch in Zukunft gezielt staatliche Großprojekte mit Steuergeldern zu stemmen. Ohne eine signifikante Unterstützung durch diese Technologieprogramme der ESA, die nebenbei bemerkt auf der letzten großen Ministerratskonferenz 2012 bereits stark gekürzt wurden, ist in der Raumfahrt auf Grund dieser Langfristigkeit eine Technologieentwicklung von der Idee bis zur Flugreife nicht zu stemmen – weder für Konzerne, noch für KMU.

Aus diesem Grunde ändert sich derzeit das Bild des politischen Klinkenputzens, wie es sich sonst vor jeder ESA-Ministerkonferenz darstellt. Denn nach dem Zusammenschluss der unabhängigen Raumfahrt-KMU Deutschlands (www.best-of-space.de) ist jetzt auch der Mittelstand gegenüber der Politik in eigener Sache sprechfähig. Den Auftakt bildete am 19. September ein langes Gespräch von Dr. Ernst Pfeiffer und Holger Sdunnus, zu dem Bundesforschungsminister a.d. Prof. Riesenhuber und der wirtschafts- und energiepolitische Sprecher der CDU/CSU-Fraktion in Deutschen Bundestag, Dr. Joachim Pfeiffer die Sprecher des Mittelstandes ins Jacob-Kaiser-Haus des Deutschen Bundestages eingeladen hatten. Im Mittelpunkt stand das Verstehen der Situation der deutschen Raumfahrt-KMU „aus erster Hand“ und die Frage nach einer angemessenen Erhöhung des deutschen ARTES- und GSTP-Beitrages zum ESA Budget. Weiterhin wurde darüber diskutiert, ob von deutscher Seite mit der benötigten und seitens KMU empfohlenen Erhöhung der deutschen Zeichnung für dieses ESA-Technologieprogramm um 35 Mio Euro pro Jahr trotz der finanziellen Engpässe bei den populären Großprojekten, die ihrerseits Milliardenbeträge beanspruchen, gerechnet werden könne. Insbesondere konnte im Dialog deutlich gemacht werden, dass sich nur so in freien Ausschreibungen eine entsprechende, dringend benötigte Erhöhung von ESA-Entwicklungsaufträgen an die mehr als 40 unabhängigen deutschen Mittelständler um insgesamt zehn Millionen Euro realisieren lässt.

Die Sorgen des Mittelstandes trafen bei beiden Experten des Bundestages auf Gehör und Verständnis; ebenso wurde in der Zwischenzeit aus regem Briefverkehr mit den ministerialen Spitzen der Administration in Berlin deutlich, dass auch hier die Botschaft des Mittelstandes auf fruchtbaren Boden gefallen ist. Noch steht eine Serie weiterer Gespräche in Berlin, Bonn und auch Brüssel an, bis zur Ministerratstagung bleiben dafür noch 60 Tage.

Eines werden sie zwar nicht ändern: Die Schlagzeilen zum Gruppenbild der ESA-Minister. Aber vielleicht dessen Hintergrund: das, was 2016 besonders wichtig ist – Beschlüsse zu Vorteil und Ertüchtigung auch des Mittelstandes, auf den es jetzt wie nie zuvor in der international hart umkämpften Raumfahrt ankommen wird.

KMU-Präsentation vor dem Deutschen Wirtschaftsrat

March 2017

Auf Einladung der Bundesfachkommission für Wachstum und Innovation des deutschen Wirtschaftsrates präsentierte HPS-Geschäftsführer DR.-Ing. Ernst Pfeiffer am 9. März 2017 in Berlin die notwendigen Ecksteine einer auf nationale und europäische „souveräne Partnerschaft“ im All gerichteten Wirtschaftspolitik aus Sicht der Raumfahrt-Zulieferer. Er betonte dabei die besondere Rolle der Fähigkeit zur Entwicklung eigenständiger kritischer Technologien und innovativer Lösungen auf Komponenten- und Subsystemlevel durch die deutschen KMU der Raumfahrt, deren Arbeitsgemeinschaft AKRK Pfeiffer als Sprecher gegenüber Politik, Agenturen und Öffentlichkeit vertritt.

In dem Zusammenhang belegte er auch klar den politisch-administrativen Handlungsbedarf zur Stärkung nicht nur der deutschen Raumfahrt-KMU-Basis sondern auch der gesamten deutschen Raumfahrt-Zulieferindustrie. Nach den Beschlüssen der ESA-Ministerratskonferenz im Dezember 2016 beträgt die deutsche Zeichnung der relevanten ESA-Technologieprogramme GSTP und ARTES lediglich 5 Prozent der deutschen Gesamtzeichnung.

Weitere Schwerpunkte der Veranstaltung galten dem Bericht aus Parlament und Fraktion durch den Vorsitzenden der parlamentarischen Gruppe Luft- und Raumfahrt, Klaus-Peter Willsch, MdB, der Frage nach einer europäischen Version von „New Space“ (Dr. Fritz Merkle, Vorstand OHB SE) und den jüngsten Startup-Plänen für die Rückkehr zum Mond (Robert Böhme, CEO von Part Time Scientists).

HPS prominent auf deutscher SATKOM-Konferenz in Bonn

March 2017

Seite an Seite und auf Augenhöhe mit den Großen der Branche wie TESAT, OHB und Airbus präsentiert sich der Mittelständler HPS GmbH auf der deutschen SATKOM Konferenz in der Bonner KAMEHA-Residenz. Besonderes Augenmerk legt das Unternehmen mit seinem großen Stand auf die zentralen Kompetenzthemen Ka-Band und Q/V-Band Antennen, große entfaltbare Antennensubsysteme der Zukunft (LDA) mit entsprechendem Metallic Mesh, De-Orbiting von Konstellationen via Drag-Sail sowie Leichtbau. Darüber hinaus erläutern HPS-CEO Dr. Ernst Pfeiffer und seine aus München mit angereisten Ingenieure in entsprechenden Kurzvorträgen den institutionellen wie industriellen Kunden vor Ort die neuesten Technologie-Entwicklungen bei HPS in den Bereichen Antennen und 3D-Druck.

Dr. Pfeiffer ist zudem auf der Veranstaltung als Sprecher der deutschen Raumfahrt-KMU auf allen Ebenen den über 300 Teilnehmern präsent. Seine Schlüsselbotschaften in Podiumsdiskussionen wie Kurzvorträgen und Einzelgesprächen: Die Zulieferer-Landschaft in Deutschland bildet ein dicht geflochtenes Netz von speziellen Fähigkeiten wie kaum in einem anderen Land. Diese Vorteile müssen genutzt werden, um im Satkom-Markt neben der Laserkommunikation auch auf anderen Schlüsselgebieten wie z.B. dem Q/V-und W-Band eine europäische Führungsposition einnehmen zu können. Innovativ, schnell, kostengünstig und flexibel sind die deutschen KMU für diese Rolle bestens aufgestellt. Die notwendige Sichtbarkeit auch über Deutschland hinaus entsteht, so Pfeiffer, jedoch erst aus der verstärkten Einbindung, Vernetzung und Arbeitsteilung der KMU im Zusammenhang mit größeren, eigens für KMU konzipierten Projekten. Gerade auch die Fähigkeit, einen eigenen europäischen Weg hin zu New Space zu legen, sieht Pfeiffer in besonders hohem Maße bei der mittelständischen Zuliefererindustrie gegeben.

Europäische Raumfahrt – Quo vadis?

May 2017

Dialog der Spitzen aus Politik und Industrie

Am 24. Mai 2017 trafen auf Einladung des BavAIRia e.V. im Hause Airbus DS die politischen und industriellen Spitzen der europäischen Raumfahrt zum Gespräch über die Zukunft der Raumfahrt und deren Anwendungslandschaft unter dem besonderen Vorzeichen von „New Space“ zusammen. Die Großkonzerne Airbus und OHB wurden vertreten durch Dr. Johannes von Thadden und Marco Fuchs, für das nationale Raumfahrtmanagement und die ESA waren Dr. Gerd Gruppe und Dr. Ulrike Bohlmann, und für den Mittelstand waren deren Sprecher und HPS-CEO Dr Ernst Pfeiffer sowie Martin Blaser von ASP gekommen, während die EU von der Vorsitzenden der Sky & Space Intergroup des europäischen Parlaments, Monika Holmeier, vertreten wurde. Künftige Anwendungen insbesondere vor dem Hintergrund der heranreifenden Leuchtturmprojekte der EU – etwa Copernicus und Galileo – wurden in einem zweiten Diskussionsblock von Repräsentanten der GNSS-Agentur, Prag, des Bundesministeriums für Verkehr und digitale Infrastruktur und ausgewählter industrieller Anwendungsspezialisten beleuchtet.

Monika Holmeier ließ keinen Zweifel an der Entschlossenheit der EU aufkommen, die europäische Raumfahrt-Agenda auf der Basis des bisher schon Erreichten kraftvoll voranzubringen, und verwies auf die auch wirtschaftlichen Erfolge der Großprojekte Copernicus und Galileo. Sie warnte dabei eindringlich vor Tendenzen der Monopolisierung durch wenige Großunternehmen und wünschte auch hier die Zusammenarbeit mit dem Mittelstand. Dennoch scheint es, wie Ernst Pfeiffer für den Mittelstand feststellte, in der europäischen „New Space“-Roadmap vor allem zwei festgelegte Rollen zu geben: Die der drei Konzerne als Primes für die staatlichen Großprojekte, und die der kleinen und teilweise noch gar nicht existenten „Startups“ für die Anwendungen. Dazwischen aber, so Pfeiffer, existiert noch ein enormes Potential beim sowohl markt- wie technikseitig seit Jahren hoch qualifizierten Mittelstand und er provozierte mit der Vermutung, dass genau dieses Potential vielfach aus dem Blick gerate, weil es schlicht nicht „politisch attraktiv“ sei wie die beiden anderen Pole, die Großindustrie durch ihr Arbeitsplatzargument und die Startup-Szene durch ihr Ideenfeuerwerk. Wenngleich diese Position nicht gänzlich unwidersprochen blieb, ließ sich jedoch am Ende der Diskussion eine gewisse gemeinsame Linie erkennen, die sich unter anderem auf drei Säulen stützt:

- Die Voraussetzungen in Europa für „New Space“ amerikanischer Machart sind weder in ausreichender Form und Masse gegeben, noch wird es als wünschenswert angesehen, das Prinzip der Nachhaltigkeit für reine Kurzfristeffekte, die später umso mehr Probleme schaffen können, auf´s Spiel zu setzen. Europa braucht seinen eigenen Weg, und hier kommt gerade dem etablierten Raumfahrtmittelstand eine tragende Rolle zu – denn Technologie ist „DIE europäische Waffe“, wie aus dem Publikum von Jörg Feustel-Büechel angemerkt wurde. Allerdings sind im Sinne fairen globalen Wettbewerbs erst einmal gleiche Voraussetzungen für alle zu schaffen.

- Die Förderung der mittelständischen Raumfahrtindustrie – insbesondere ihrer besonders stark in Deutschland ausgeprägten Kompetenzlandschaft – ist eine nationale Priorität von wachsender Dringlichkeit, da sie in besonderer Weise durch Schlüsseltechnologien von Zulieferern für deutsche Primes die souveräne Partnerschaftsfähigkeit Deutschlands erhält.

- Optimierungspotential hinsichtlich der Geschwindigkeit der Prozesse besteht – etwa bei Förderentscheiden, Exportlizenzen oder auch parlamentarischen Prozessen – und kann gerade im Hinblick auf die Dynamik der Entwicklung von administrativer Seite noch gehoben werden. Denn jede Erhöhung der Schlagzahl ist auch ein Schritt auf dem Weg zur Bewahrung eines unabhängigen europäischen Wegs in die Zukunft einer an Sinnhaftigkeit und Nachhaltigkeit orientierten Raumfahrt.

In Conclusio:

- Raumfahrt hat generell eine große Zukunft; Bayern, Deutschland und Europa müssen sich nur entscheiden, ob sie mit eigenständigen Leistungen als souveräner Partner dabei sein wollen – oder eben nicht.

- Horizon 2020 bietet unterkritische Gewinnchancen durch Budgetrestriktionen bei enormem europäischen Bieterandrang; zusätzliche Anreize gerade für qualifizierte Unternehmen sind dringend zu schaffen

- Die Politik erwartet Ideen und konkrete Bedarfsformulierungen für die Entwicklung von „Infrastrukturen“, die sie auch der terrestrischen Anwenderindustrie anschließend zur Verfügung stellen kann. Insbesondere das Bundesverkehrsministerium zeigte sich hier außergewöhnlich aufgeschlossen.

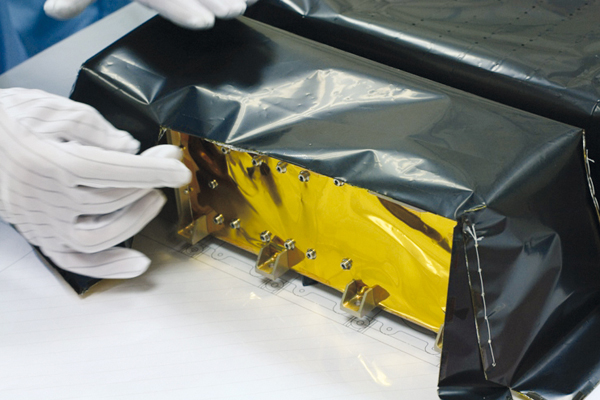

German Space Agency (DLR) Awarded TRISTAN-C Contract to Thales Alenia Space in Germany (TAS-DE) with HPS as Subcontractor

October 2017

On 4th of August 2017 the German Space Agency (DLR) agency has awarded the TRISTAN-C activity to Thales Alenia Space in Germany, aiming at the development of a new material for electronic housings to foster the use of COTS electronics in space. As referencecase a high-speed on-board computer electronic equipment of TAS-DE was chosen. The kick-off took place on 4th of September at the agency in Bonn. HPS Germany has been contracted for the development of the electronic housing.

With this contract the German Space Agency DLR takes Thales Alenia Space in Germany on board its Component Initiative to develop and realise innovative space technology for increased competitiveness.

The first ideas date back in 2005 when the use of CFRP was considered for electronic housings and HPS had been contracted by ESA for a related technology study. In the meantime HPS has performed several developments on CFRP electronic housings for different applications and in contract to different customers. In each contract different targets have been in focus (thermal, structural, electromagnetic shielding, radiation shielding, production process); TRISTAN-C now combines all of them in parallel.

Although the similar thermal expansion of CFRP electronic boxes simplifies the mounting on the CFRP panels of the satellite, the major innovation is the development of a new hybrid composite material. It balances the mass saving against improved space radiation shielding while solving also the thermal and electrical conductivity issues.

LEA – A New Chapter in Europe´s Declaration of Non‐Dependence in Space

October 2017

Authored by the HPS – the „M“ in European Space SME

„Technology“ means „knowledge how to solve problems by applying technical solutions“. In the absence of abundant natural resources technology is nothing less than the key to self‐determination and liberty as the highest societal value in a free world.

Therefore, the European Commission (EC) dedicates with high priority comprehensive programs to …“

More information can be found in the LEA_Press_Release_1 and in the article of Space Intel Report

EUCLID: ESA-Project to Search for Dark Matter and Energy takes Crucial Step

December 2017

HPS Germany receives STM-acceptance for first model of the central antenna unit

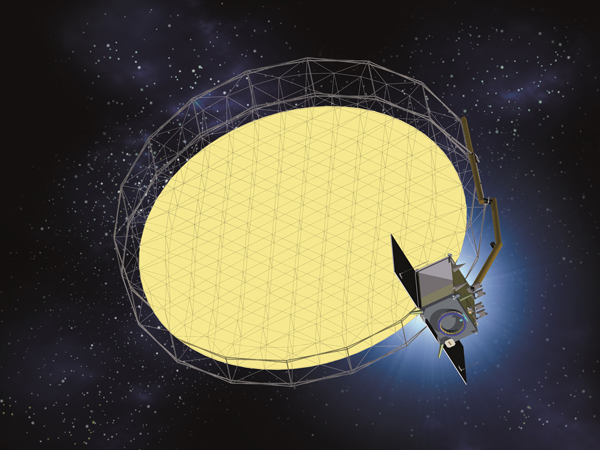

Albert Einstein is supposed to have said that only two things are unlimited: human stupidity and the universe. Concerning the universe, however, he was not sure, because the central power of gravity rather supports the contraction than the expansion of matter. Meanwhile, and based on theoretical models only, scientists are pretty certain that indeed there must be a third and even stronger power than gravity in the universe, counteracting its effects: A dark energy field, making up for 68 percent of all energy in the universe, supporting its unlimited expansion. Even more, it is believed that about 80 percent of matter in the universe consists of something that nobody has seen, yet: Dark Matter, that makes up for 27 percent of energy density in the universe, while Baryonic matter – the stuff that everything is made of that we know – contributes just five percent. Finding out about both is the target of EUCLID, the new space telescope of the European Space Agency ESA.

On June 27th, 2013, ThalesAleniaSpace Italy (TAS-I) has been assigned the task to coordinate the development of the spacecraft which will orbit the sun from 2020 to 2026 at a distance of 1.5 million kilometers from earth in order to 3D-map the Dark Matter of up two billion galaxies.

EUCLID is going to work with two instruments covering the visible and the near infrared domains.

Measurement results and stored telemetrical data will be sent to the ground station through a central adjustable antenna with a diameter of just 70 centimeters using K-Band (26 GHz) to transmit up to a max of 850 GB during four hours per day. The telemetry data are going to be transmitted via X-band; EUCLID itself is also controlled through X-band.

The Spanish subsidiary of ThalesAleniaSpace, TAS-ES, ordered the complete set of design, analysis, manufacturing, integration and testing of the K-band antenna structure assembly at the European antenna-specialist HPS Germany – the company that is highly renowned in Europe and beyond since more than 12 years for successful design and production of ultra-precise antennas for spacecrafts and satellites; absolute reliability of the EUCLID-ARA (Antenna Reflector Assembly) is simply one of the central preconditions for the success of the whole mission – a mission that is run by a consortium of almost 1,000 scientists from 100 institutes and 13 European countries plus even one from the United States. All images from both instruments on board will be transmitted via this one central antenna.

The HPS-design for the EUCLID-antenna is based on a special, highly conductive carbon fibre technology to keep the antenna extremely light, precise and robust in an environment that is characterized by widely changing temperatures at 1.5 million kilometers from earth; the antenna has to keep up reliable service out here for a mission duration of six years.

HPS has executed an detailed test campaign to verify design and technology of the reflector. The antenna proved to withstand thermal cycles and vibration tests, not only keeping the desired accuracy, but in parts even surpassing the specifications required for flawless data transmissions . To make clear what that means in practice: the permissible geometrical production tolerance here is lower than 50 µm, equivalent to the diameter of a human hair, while the acceptable degree of the antenna´s focal pointing tolerance due to temperatures between -45 and +135 degrees centigrade in space is limited up to just ten thousands of one angular degree. To put that also into perspective: this is like observing from earth the deviation of two points which are actually just 70 kilometers away from each other on the moon.

In addition, the extremely good relation of mass (4.5 kg) to rigidity (> 150 Hz Eigenfrequenz) is yet another special and valuable quality of this HPS antenna technology.