MTG-S1 and Sentinel-4 with Reliable Thermal Hardware from HPS

November 2025

MTG-S1 and Sentinel-4 with Reliable Thermal Hardware from HPS

November 2025

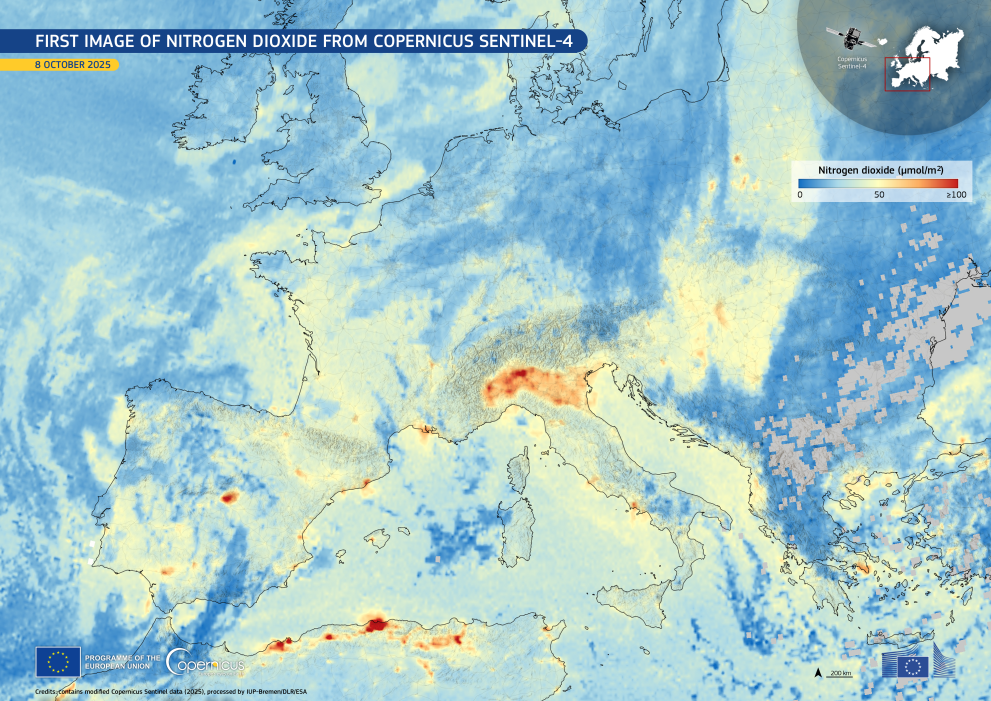

With the successful operational launch of ESA’s MTG-S1 (Meteosat Third Generation – Sounder) mission, a new era in Earth observation has begun. On board is the highly sensitive Sentinel-4 instrument, which is now capturing air quality data in real time with previously unattainable precision – from around 36,000 kilometres up in geostationary orbit.

The journey there, the harsh environment itself, and the high-tech observation cameras all place extreme demands on every technical component: vacuum, intense solar radiation, dramatic temperature fluctuations between day and night sides. Only perfectly protected technology survives. This is where HPS comes in with its

High-Tech “Packaging” from a Single Source: Thermal Hardware Components by HPS

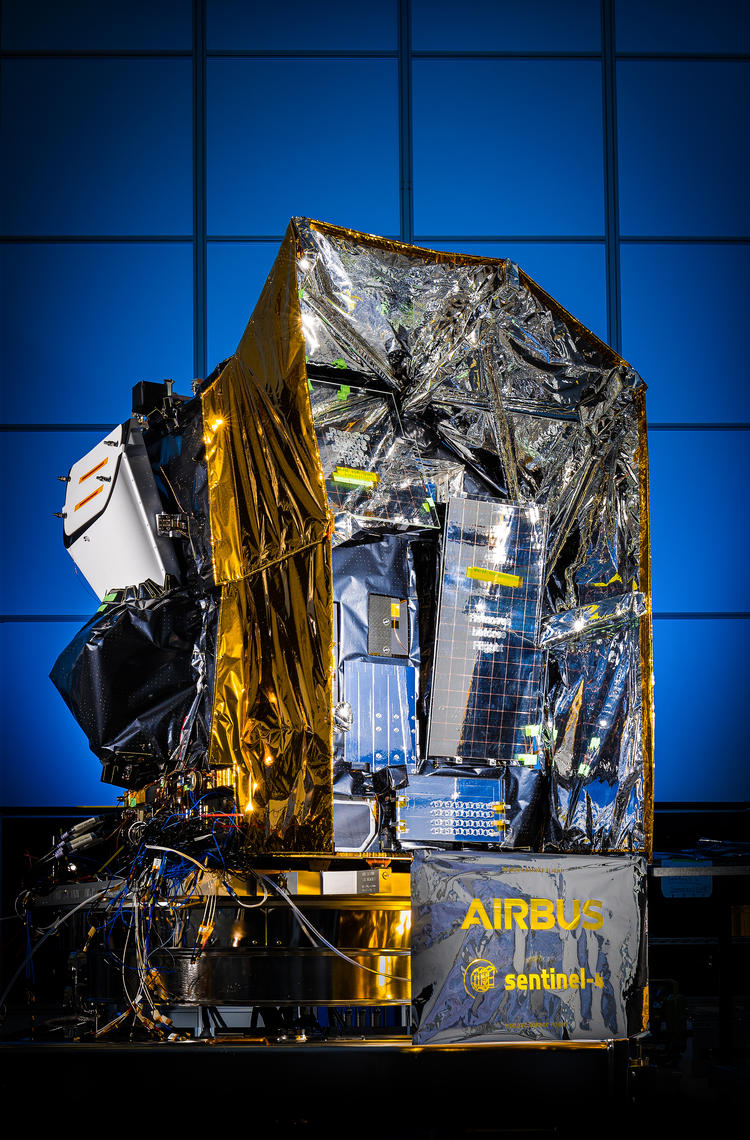

The Munich-based space technology company HPS was commissioned by OHB-Bremen, with Prime Airbus-Deutschland and end-customer ESA, for the design and production of all thermal hardware components on Sentinel-4 for this mission – a key role in its success. At the centre of this is the so-called Multilayer Insulation (MLI): a multi-layered insulation foil (see image, foil in gold/silver colour) that protects the most sensitive systems against overheating, overcooling or temperature gradients. This portfolio is complemented by radiators (see image, reflective plates), also supplied by HPS.

With this comprehensive thermal hardware package “from a single source”, HPS sets itself apart from the competition – and establishes new standards in reliability and system expertise.

Sentinel-4: Custom Protection for an Optical Precision Instrument

The optically complex Sentinel-4 instrument in particular demands special attention. To minimise stray light, a black MLI was developed – specifically for this application. In addition, a special “Sunshield MLI” protects the sensitive radiators of the instrument from direct sunlight – a central contribution to maintaining functionality in space.

As early as 2018, the MLI for Sentinel-4 was produced by HPS and integrated into the spacecraft system by the customer from 2021 to 2022, with on-site support from HPS. The MLI for MTG-S1 equipment was already manufactured in 2017 – an impressive example of long-term reliability and forward-looking planning within the European space programme.

International Success Story

The implementation took place in close cooperation between the locations of the HPS Group: the design was created in Munich, production was initially handled by the then subsidiary in Porto, today successfully complemented internally by the new HPS competence centre in Bucharest, which now plays a key role – especially in MLI and thermal straps.

This mission is exemplary of the HPS success model: an international team, high engineering expertise, continuous quality assurance, and absolute reliability – from concept phase to flexibility in final integration.

Future-Proof – Also for NewSpace

HPS is thus not only a proven partner in major ESA missions with clients such as OHB, Airbus, and ESA itself. NewSpace customers and operators of small satellites also find an experienced, flexible, and technologically leading partner in HPS – whether from Germany (HPS-DE) or directly from Romania (HPS-RO) for ISO8 satellite/equipment classes. With MLI from HPS, Europe’s space technology is on the safe side.

Picture by Airbus Defence & Space GmbH by Ralf Maurer