Radiators

Radiators are one component of a thermal control subsystem, whose goal is to discharge through radiative heat transfer mechanisms any waste heat into deep space. The overflow of thermal energy may come either from the spacecraft (i.e. its electronics) or from the space environment.

Transporting this excess of energy wisely from the heat source towards the radiator, distributing the heat uniformly over the emitting surface and to reject the heat efficiently comprehend a multidisciplinary challenge that is critical for many of the space projects. From engineering models up to flight models, HPS has primed in the design, manufacture and test of radiators in many different projects.

Contact:

For further information please contact our chief engineer.

References:

→ Success Trajectory

Metal Radiator

Metal Radiator:

As market trade-off, aluminum radiators take advantage of the high thermal conductivity of aluminum and its relative low density. The good machinability of Aluminum enables the achievement of relative complex emitting surfaces at good prices. Radiating surfaces can be adapted in order to enhance the thermo-optical properties by adding different surface finishes or attaching optical solar reflectors (OSR).

CFRP Radiator

CFRP Radiator:

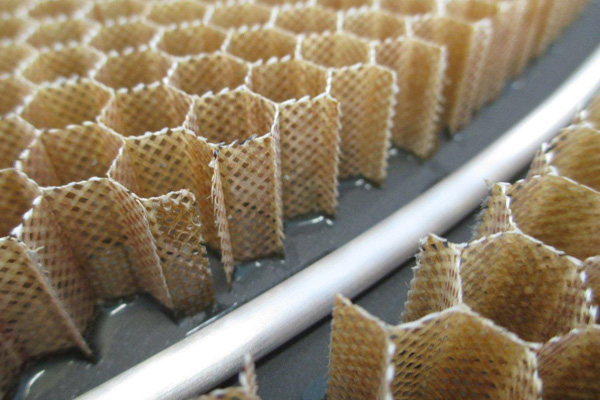

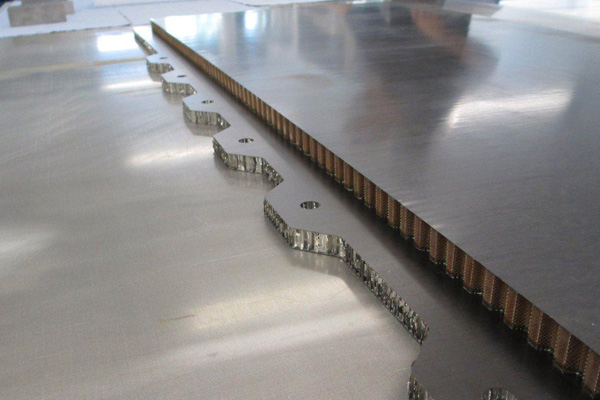

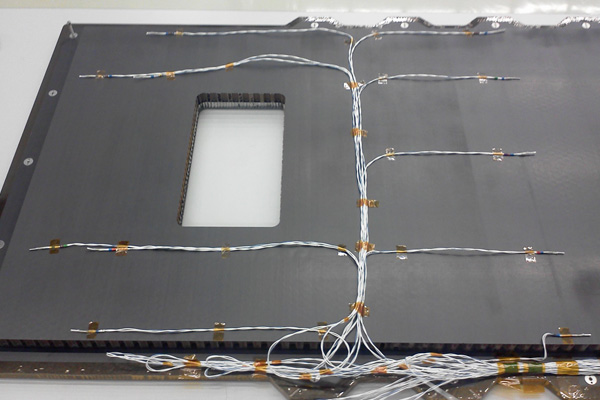

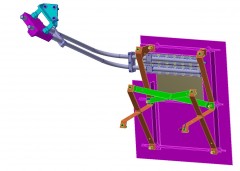

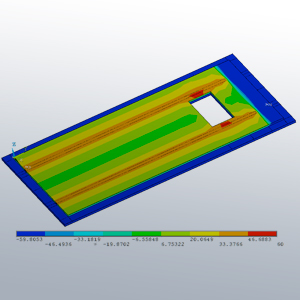

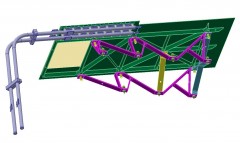

High thermal conductivity fibers (unidirectional). Assembled perpendicular to the axis of the cooling pipe.

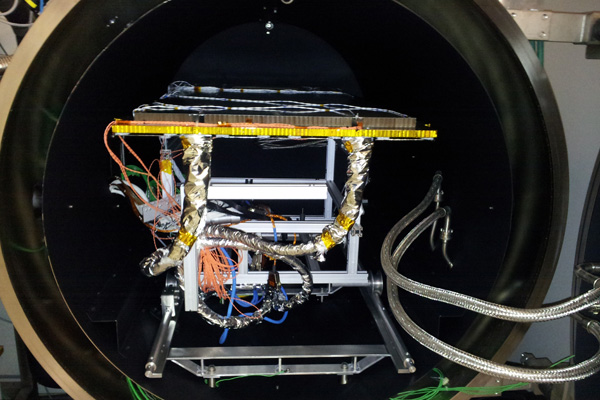

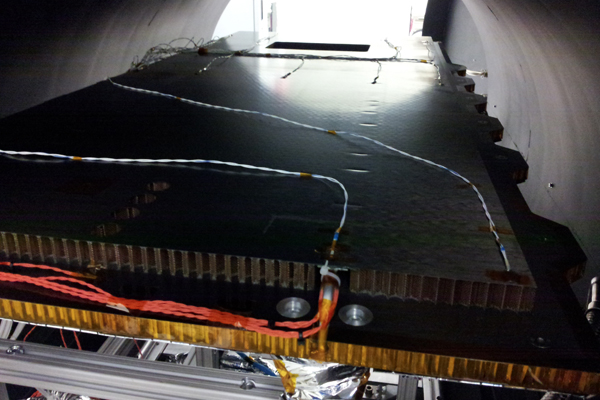

Parallel study in an investigations on doping with Carbon Nanotubes to increase the thermal conductivity of the material. TVC test on Breadboard Level, see figure left.

Product Example CFRP Radiator:

- Dimensions: 0.6 m x 1.4 m

- Mass: 1.3 kg

- Mass per Area 1.55 kg/m²

OSR Bonding Material

OSR Bonding Material:

Optical solar reflectors (OSR) consist of a top layer made out of quartz glass and covered with a reflecting metal layer.

It provides high emittances in the infrared- and a low absorptivity in the sun spectrum. Therefore it is one of the best choices for space radiator application.

OSRs are typically provided in a rectangle shape and can be bonded to almost any substrate (CFRP, aluminum etc.).

- Emission Coefficient ~0.8 [-]

- Absorption Coefficient ~0.1 [-]

- Dimension ~40×40 [mm²]

HPS is procuring the OSRs from different sources, the know-how of HPS lies in the gluing process, mating OSRs with radiator substrates.