New Materials & Process

In einer großen Reihe nationaler und internationaler Entwicklungsprojekte hat HPS über ein Jahrzehnt lang die Erkenntnisse über Materialverhalten und Materialeigenschaften wie auch Rezepte für bestimmte Anwendungen in einer mittlerweile in dieser Form einzigartigen Datenbank sammeln und aufbereiten können. Auf Grundlage des gewonnenen Knowhows hat sich HPS in der europäischen Raumfahrtindustrie die führende Position im Bereich Carbon Nanotubes erarbeitet und ist dabei, Nischen für weitere Einsatzmöglichkeiten neuer Materialien systematisch zu erschließen – wie etwa Materialhybride für Verbindungen oder zur Abschirmung von Strahlung. Auch im Bereich von 3D-Druck für Raumfahrtanwendungen setzt HPS derzeit seinen Schwerpunkt. Die Führung von Forschungs- und Entwicklungsprojekten dieser Art mit deutschen und europäischen Partnern aus Wissenschaft und Industrie liegt aufgrund der anerkannten Expertise mittlerweile zumeist bei HPS.

Kontakt:

Bei Fragen wenden Sie sich bitte an unseren leitenden Ingenieur.

Referenzprojekte:

→ Success Trajectory

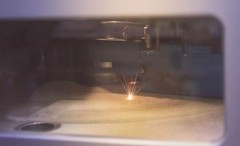

Additive Manufacturing (AM; 3D printing)

Features:

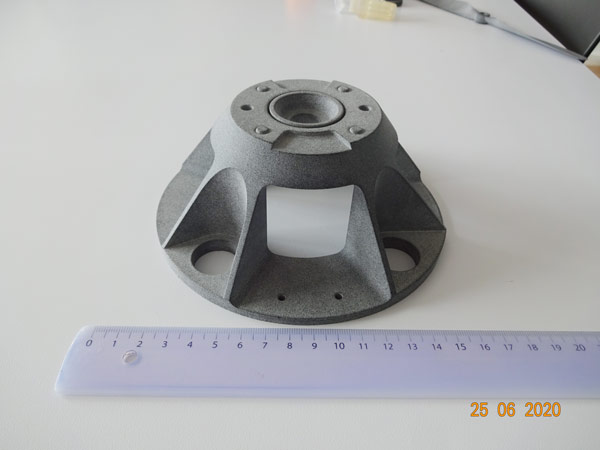

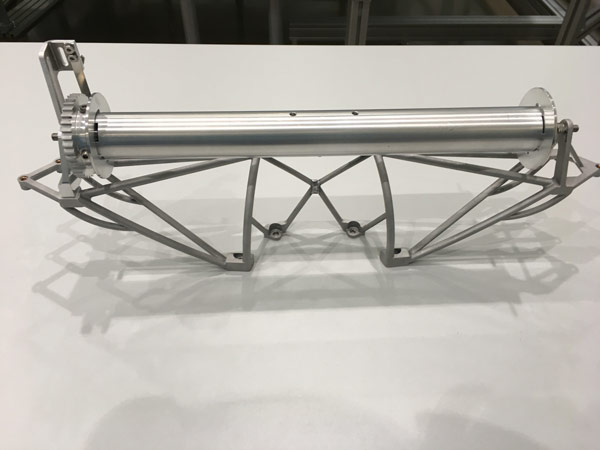

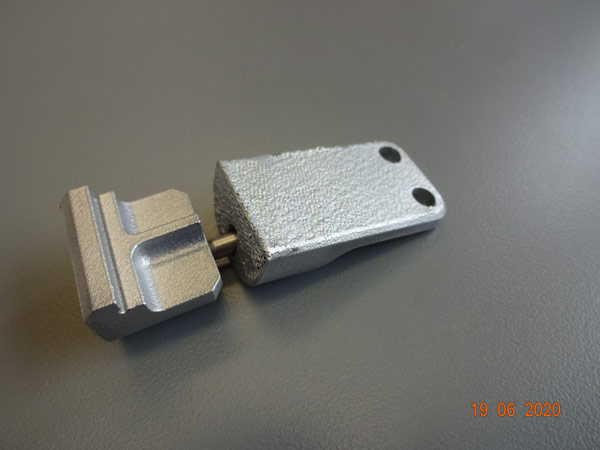

- Additive Manufacturing of:

- Antenna (Ti)

- Radiator Baffle Support Structure(Al)

- Hinge (Ti)

- Support Bracket (Al)

- Radiation Shielding (different materials)

- Mock-Ups / Test equipment/Tools

- Rapid Prototyping Models

- Biomic design possibilities

- Reduced assembly effort by less components

- Mass and cost saving

- Own design & MAIT guidelines according ECSS

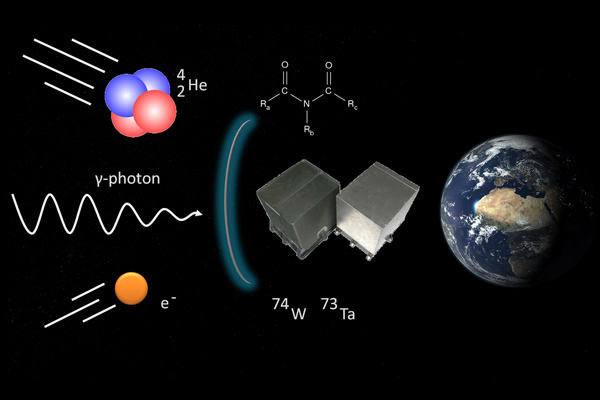

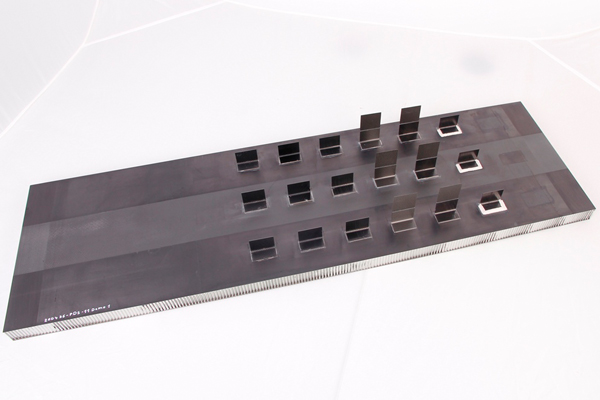

Radiation Protection Materials

Features:

- Protection of single electronic-elements up to complete satellites

- Implementation of new materials and material combinations

- Combination with CFRP (embedded or applied on top like MLI)

- Specific needs e.g. on ESA‘s JUICE mission to Jupiter

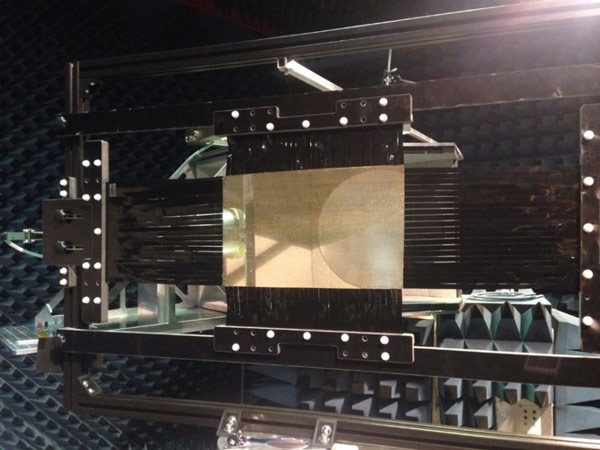

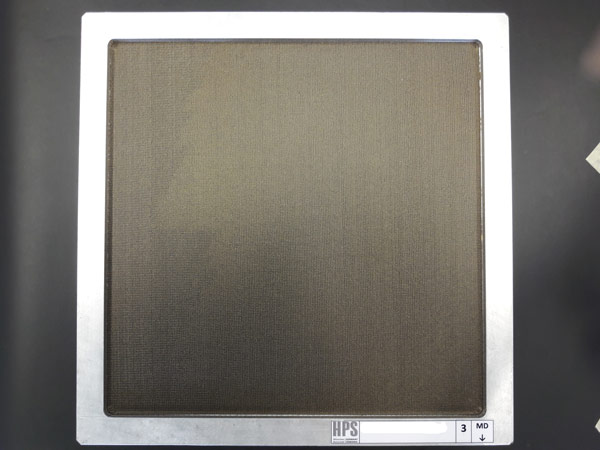

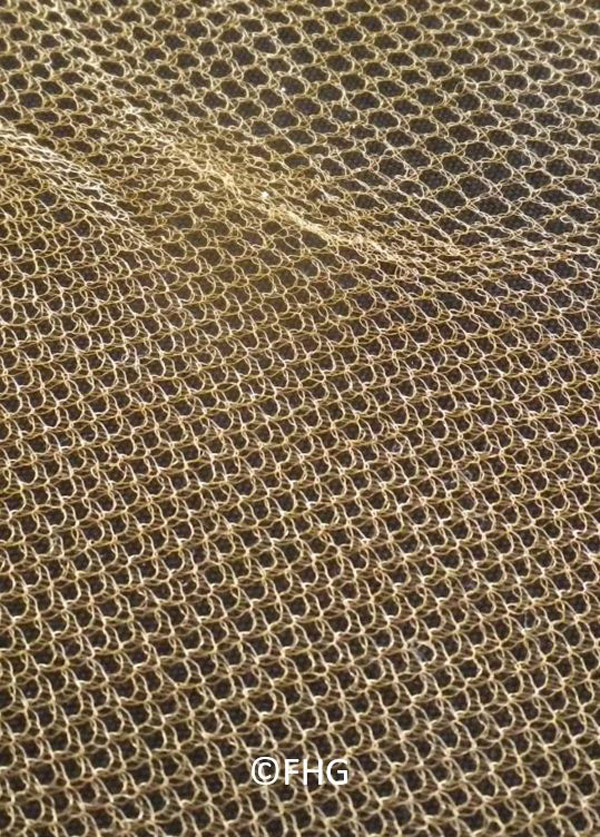

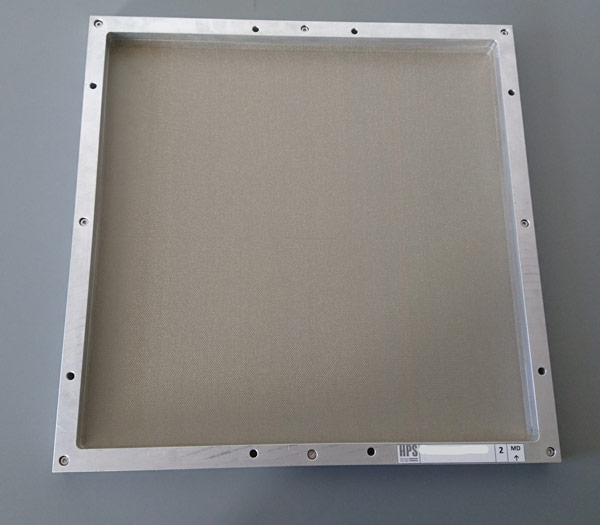

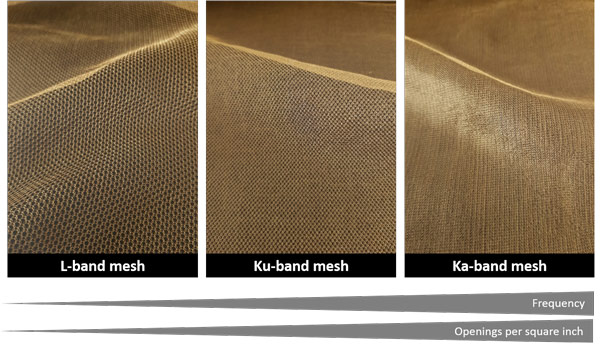

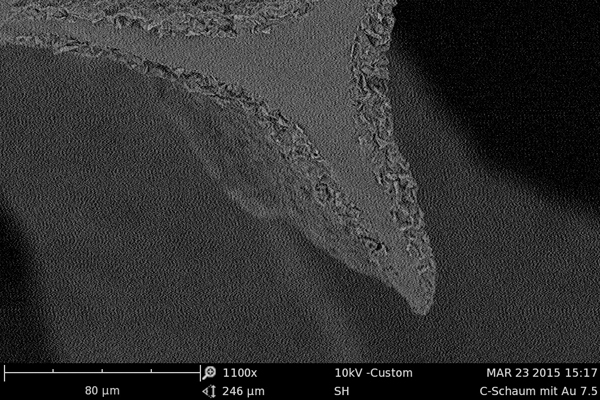

Reflective Metallic Mesh

Features:

- Application as reflective surface for Large Deployable Reflector Subsystems (LDRS) and solid reflector antennas

- High drapable and foldable

- Extremely lightweight and robust

- High electrical conductivity

- Different knitting patterns: e. g. Atlas, Tuch, Tricot

- Openings per Inch (OPI): 18 and higher

- Wire material: gold-plated tungsten or molybdenum

- Wire diameter: thinner than hair

For more information please visit HPTex

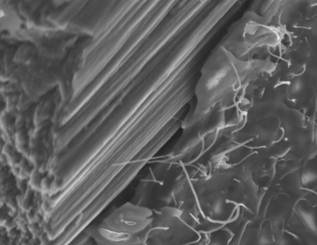

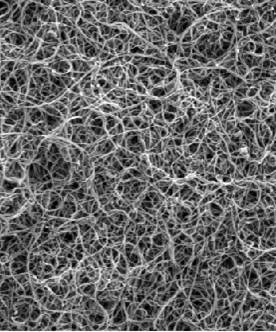

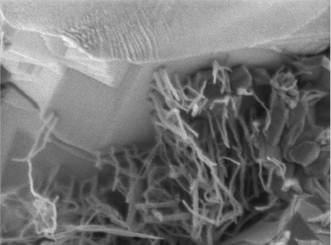

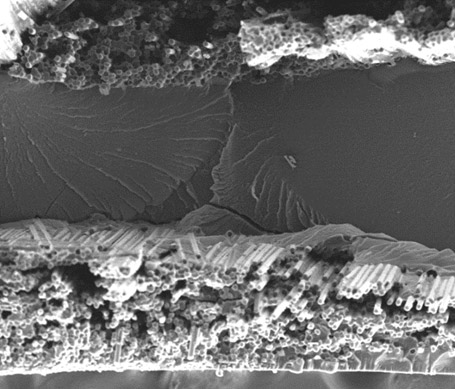

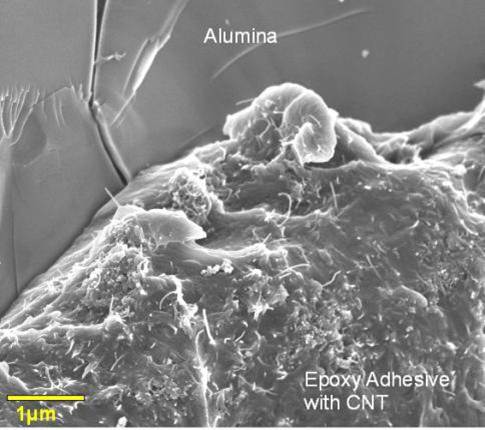

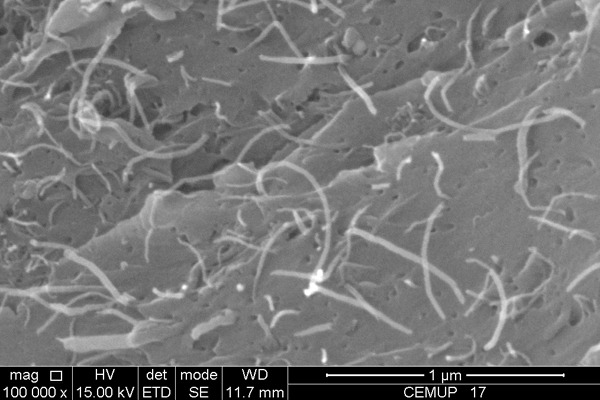

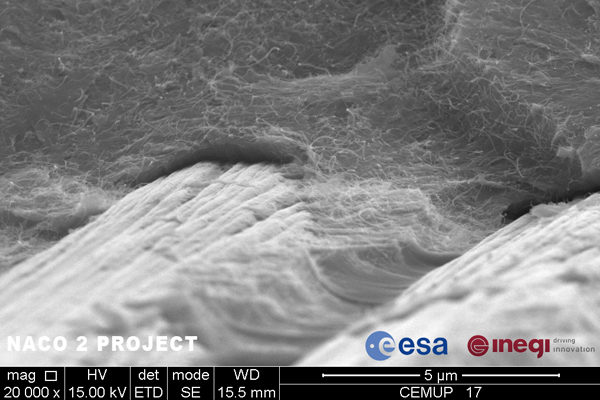

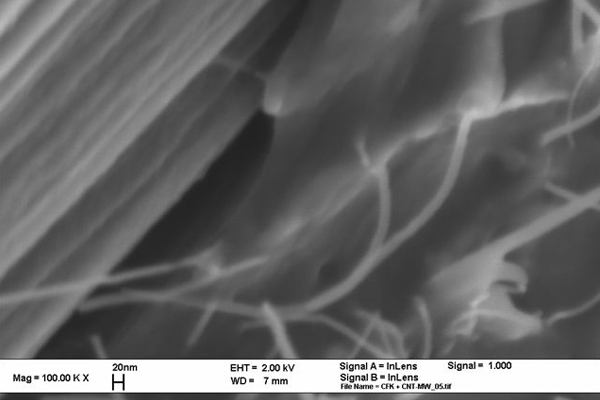

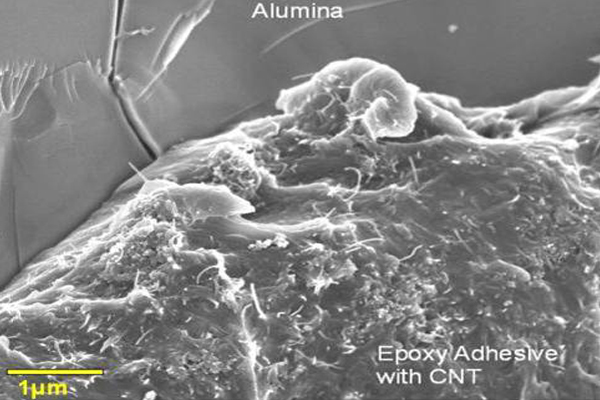

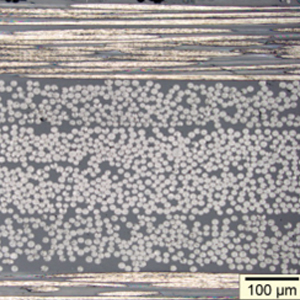

Carbon Nanotube Based Composites (CNT)

Features:

- Application for electronic housings, optical baffles, radiators, satellite structures, joints & adhesives, tribology

- More than 10 development projects performed in contract to ESA or nationally co-funded or internal funding since 2005

- HPS Germany mostly leading the development

- Collaboration with Austria, Portugal, Greece, Czech Republic, France

- Carbon Nanotubes, Graphenes, Carbon Black, other nano-materials

- In combination with CFRP, metal, ceramic or only with polymer resin

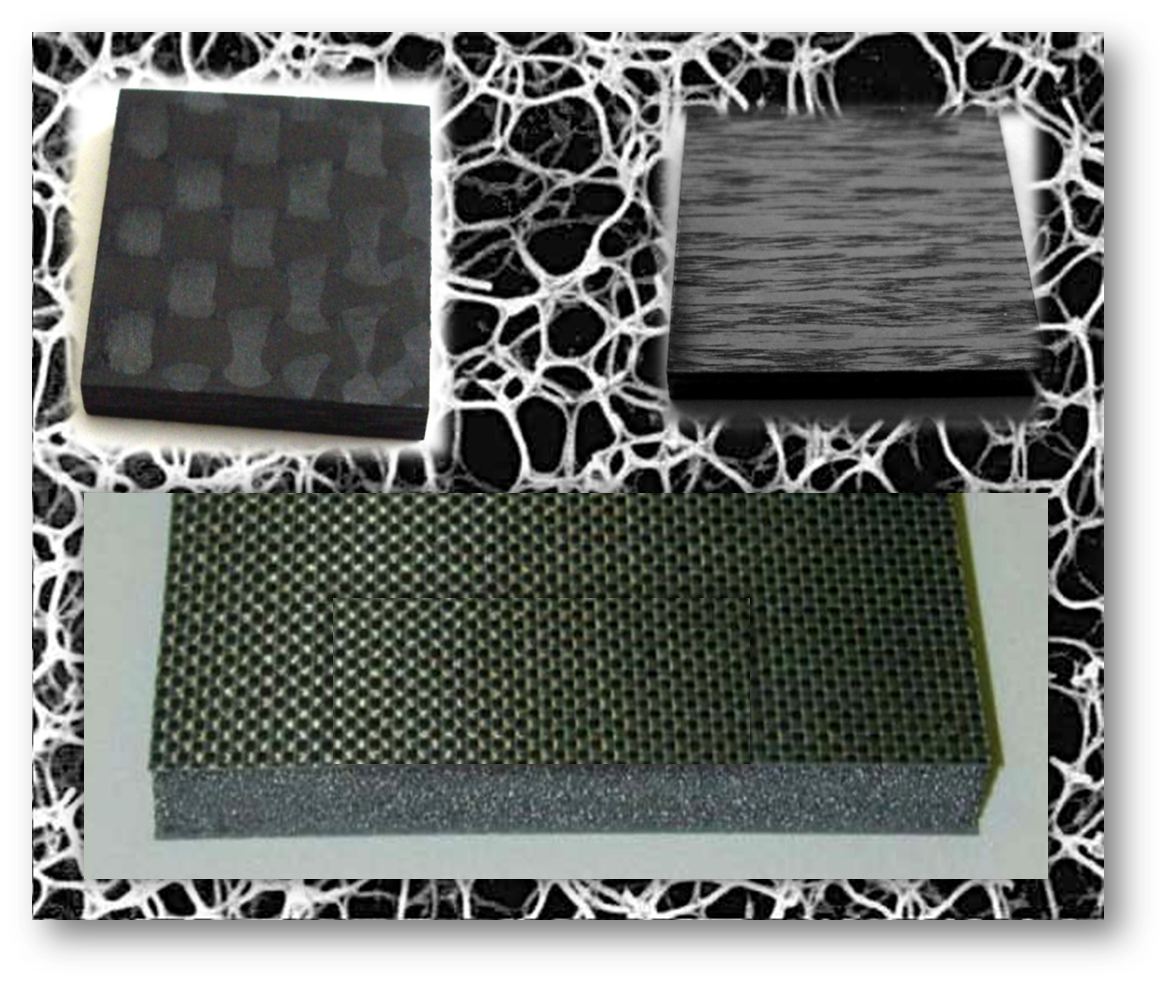

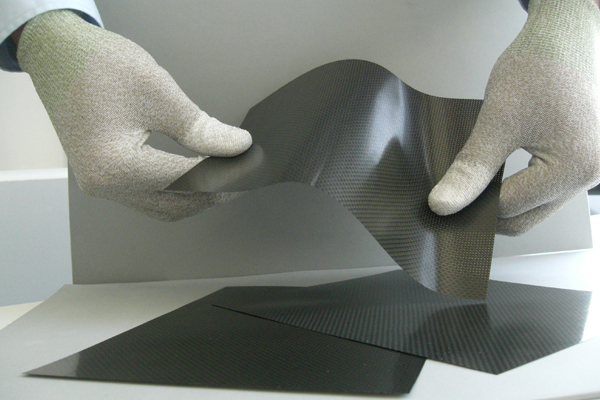

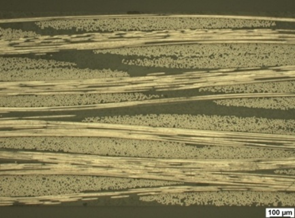

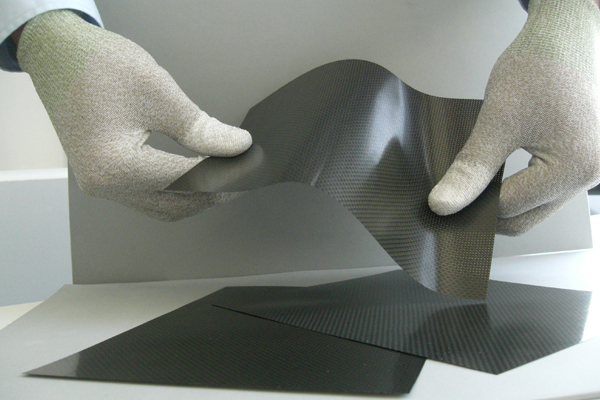

Composite Materials in General

Features:

- PAN-fibre- & pitch fibre composites

- Epoxy- or cyanat ester resins

- CFRP honeycomb core

- Glass fibre or aramid fibre composites

- Joining with titan sheets or metal joints