März 2016

Taking the Next Step in ESA´s Clean Space Initiative

ESA-Prime HPS with SME-Consortium Ready to Build New Generation De-Orbiting Subsystem

Hardly any messages have dominated the space community´s discussions in the past two years as perseverently as these two:

- the debris from past satellite missions forms a growing threat to future endeavors in space

- the number of satellites expected to form future constellations especially on LEO is exploding since new players are discovering space as their domain

- which again multiplies the problem of future debris.

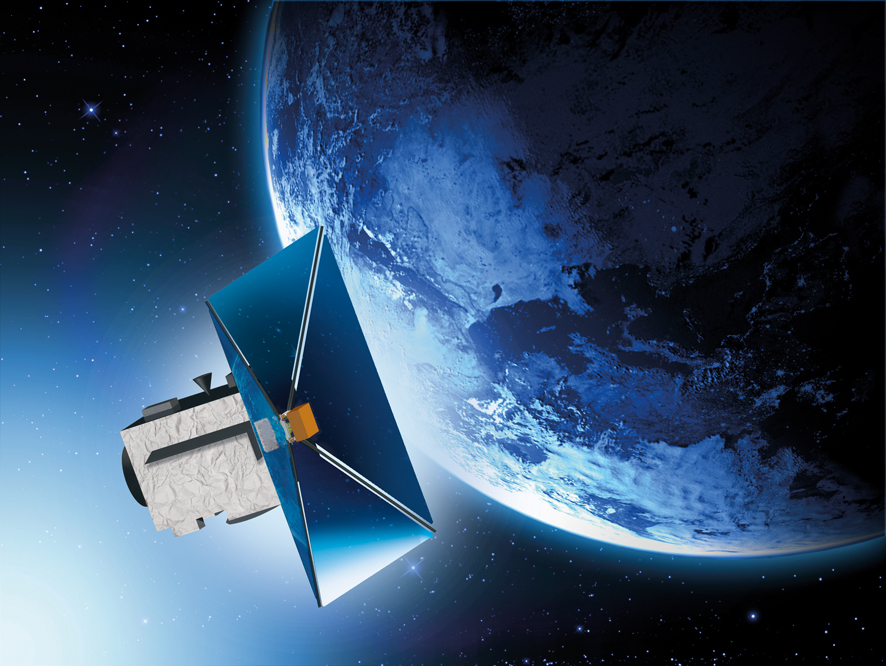

So, on the one hand enormous growth of the satellite business is to be foreseen, on the other hand this business needs better rules in order to be sustainable. „Clean Space“ is ESA´s answer in general and the quest for a new, fully ecological de-orbiting sailsystem in particular.

While currently satellite manufacturers are already facing problems to comply with the 25-years-deorbiting „guideline“ without minimising the effectiveness and increasing the cost of their missions, ESA now aims to make this period as a strict requirement leaving neither ecological nor economical footprints.

Capitalizing on previous research and development in this area like the precursor project ADEO, led by the subsystem prime HPS with its consortium of DLR-institutes in Bremen and Braunschweig and the SMEs Etamax and HTS, ESA now announced its expectations for a full fledged demonstrator ready to fly by 2018 with a deorbiting time of lower than 5 years. The new project will be ignited this year and ESA´s subsystem prime HPS is expected to take this next step towards the final breakthrough in deorbiting technology, too, because:

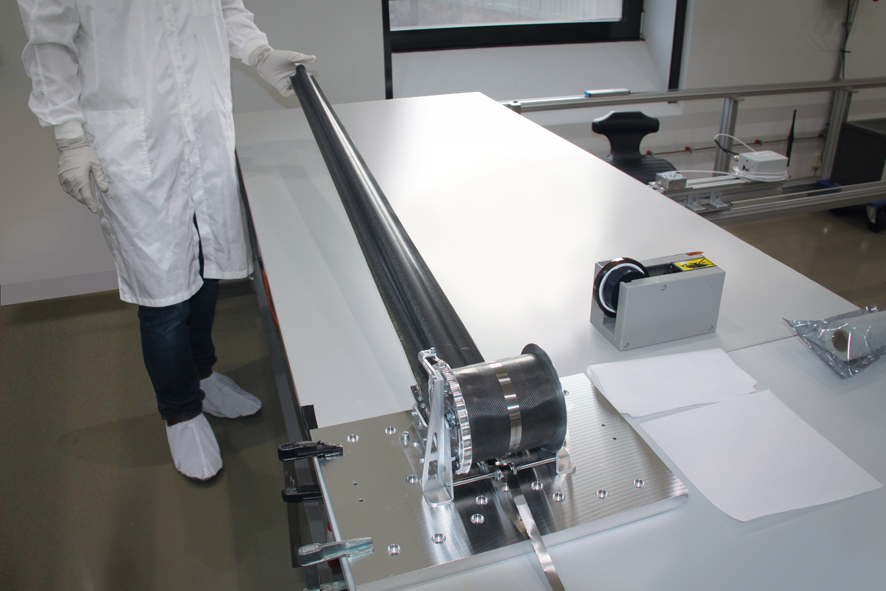

- the current HPS precursor project ADEO, featuring a 5m x 5m deployable boom and sail subsystem weighing just 20kg, has been successfully tested on breadboard level in February 2016 and will reach design maturity for an Engineering Model manufacturing and assembly through a CDR in these days in March.

- ADEO will then already fulfill the requirements of providing sail and boom materials able to withstand the very severe Atomic Oxygen (AtOx) and Ultra Violet (UV) environment, offering scalability down to 100-kilo-satellites down from the current reference case of spacecrafts at 1-1.5 tons of weight, and of providing reliable deployment technology tested under ambient conditions and in a vaccum chamber in mid 2016.

HPS as ESA subsystem prime is aiming at the follow-on project also with its proven partners.

In parallel and as leading specialist on deployable structures and antennas, HPS Germany acts as prime contractor for Large Deployable Antennas (LDA) in cooperation with the German SME LSS, while the HPS subsidiary in Portugal is working on a deployable highprecision mast system (10-20m) for instruments weighing 100-250 kg on science missions.